Control system and control method for movement of welding machine

A control method and control system technology, which is applied in the field of large-scale, high-precision welding machine mobile control systems, can solve problems such as inapplicability, achieve high efficiency, easy system operation, and avoid manual input of position parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

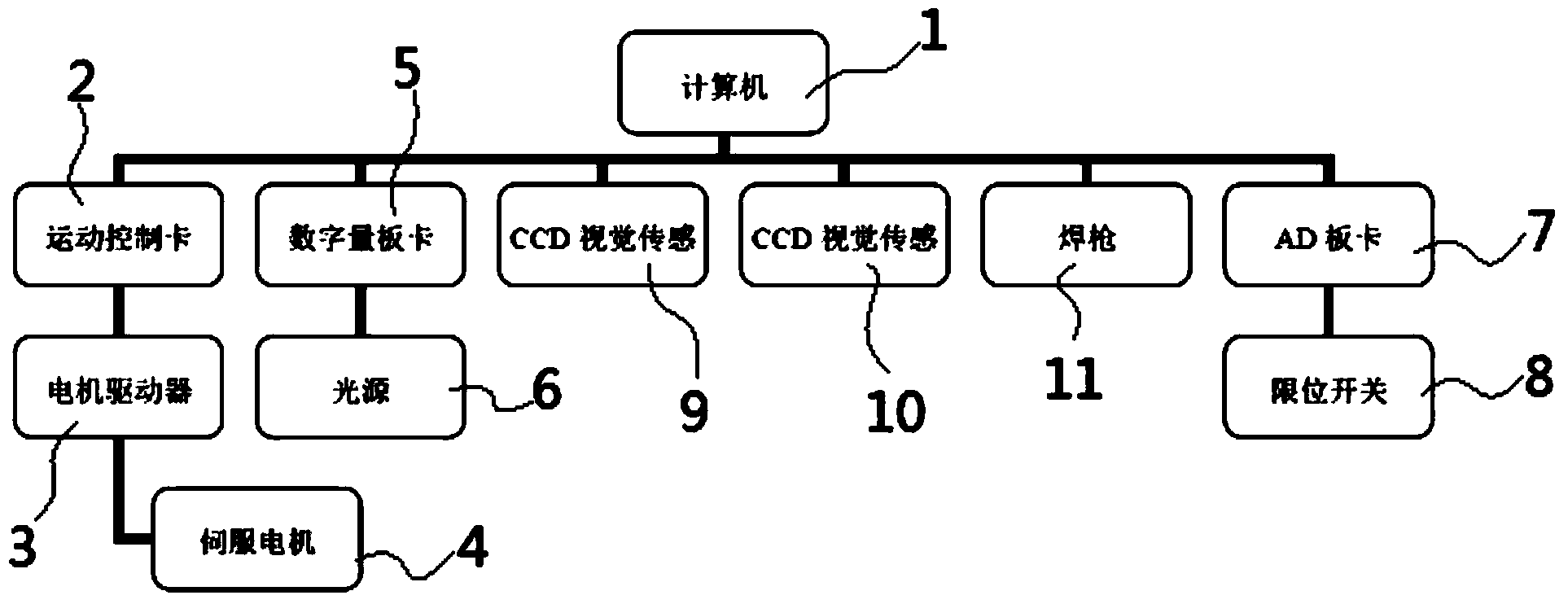

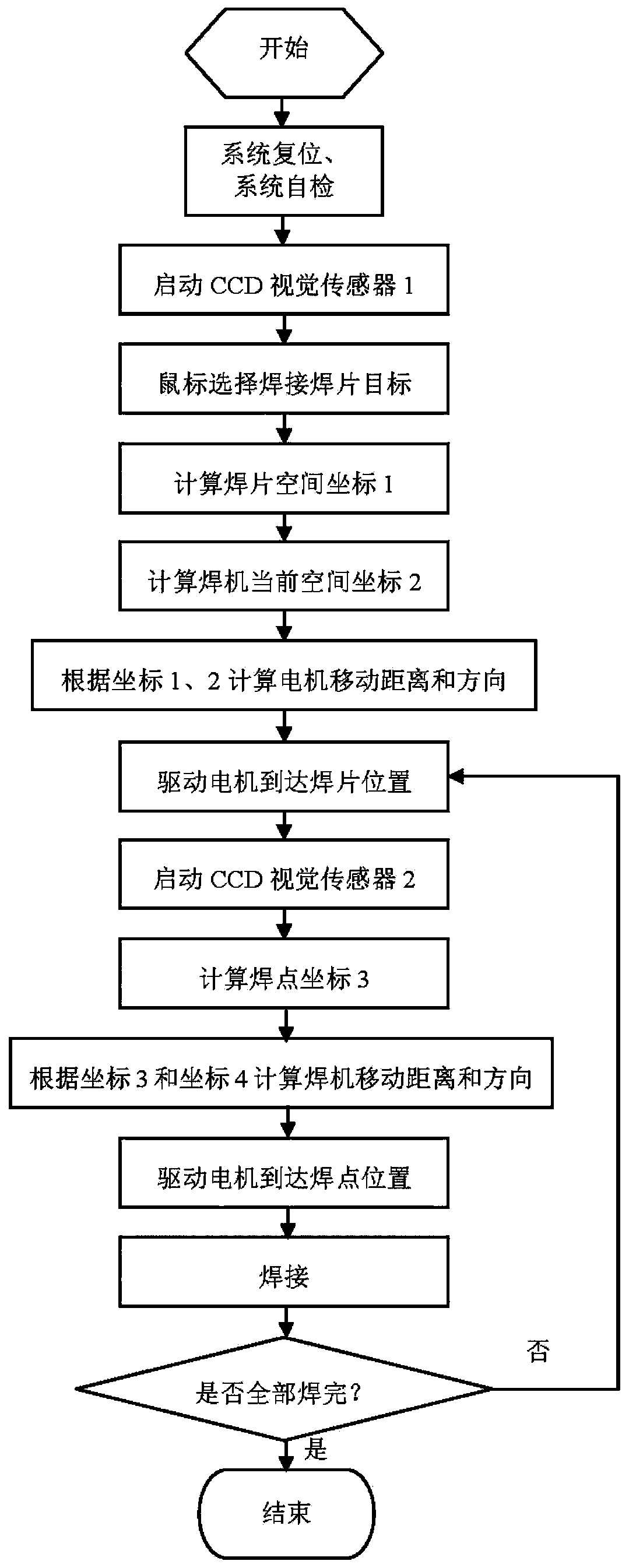

[0045] see figure 1 , which shows a structural block diagram of the welding machine mobile control system provided by the present invention. As can be seen from the figure, the control system is mainly composed of control host 1, motion control card 2, motor driver 3, servo motor 4, digital quantity board 5, light source 6, AD board 7, limit switch 8, and the first CCD visual sensor 9 and the second CCD vision sensor 10 and track (not shown in the figure) cooperate to form.

[0046] Wherein, the track provides a moving path for the welding machine to move, which is distributed relative to the area to be welded, and provides a longitudinal and a horizontal moving path for the welding machine.

[0047] The limit switch 8 is a through-beam photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com