Process for converting tallow to diesel fuel

a technology of tallow and diesel fuel, which is applied in the field of internal combustion engine fuel, can solve the problems of poor cold weather performance, cumbersome and relatively expensive process, and poor cold weather performance of biodiesel derived from tallow, and achieves the effect of improving cold weather performance and improving cold weather performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

[0035] The tallow was purchased per the specifications provided by the British Government from a company, Taylor By Products, in Pennsylvania and trucked down to Charleston. As the tallow was solid, steam was applied to the truck heating system which brought the tallow to a liquid at 160° F. The tallow was processed as a single feedstock stream. The processing yields were 83% #2 diesel fuel with flash point of 145° F. and perfect distillation curve. The pour point was measured down to −18° F. and the end product was almost clear. The lowest temperature for attained was only −18° F. as it was the lowest temperature achievable on site. The actual pour point is expected to be lower. The tallow-derived product had no sulphur at all and it is anticipated that the mixture for biodiesel should be something on the order of 40% tallow diesel mixed with refined mineral diesel, i.e., diesel purchased to blend with or diesel made from waste oils as described in U.S. Pat. No. 5,885,999.

example two

[0036] In order to gain greater detail on the resulting product a laboratory scale process was set up mimicking the foregoing conditions.

Laboratory Methodology

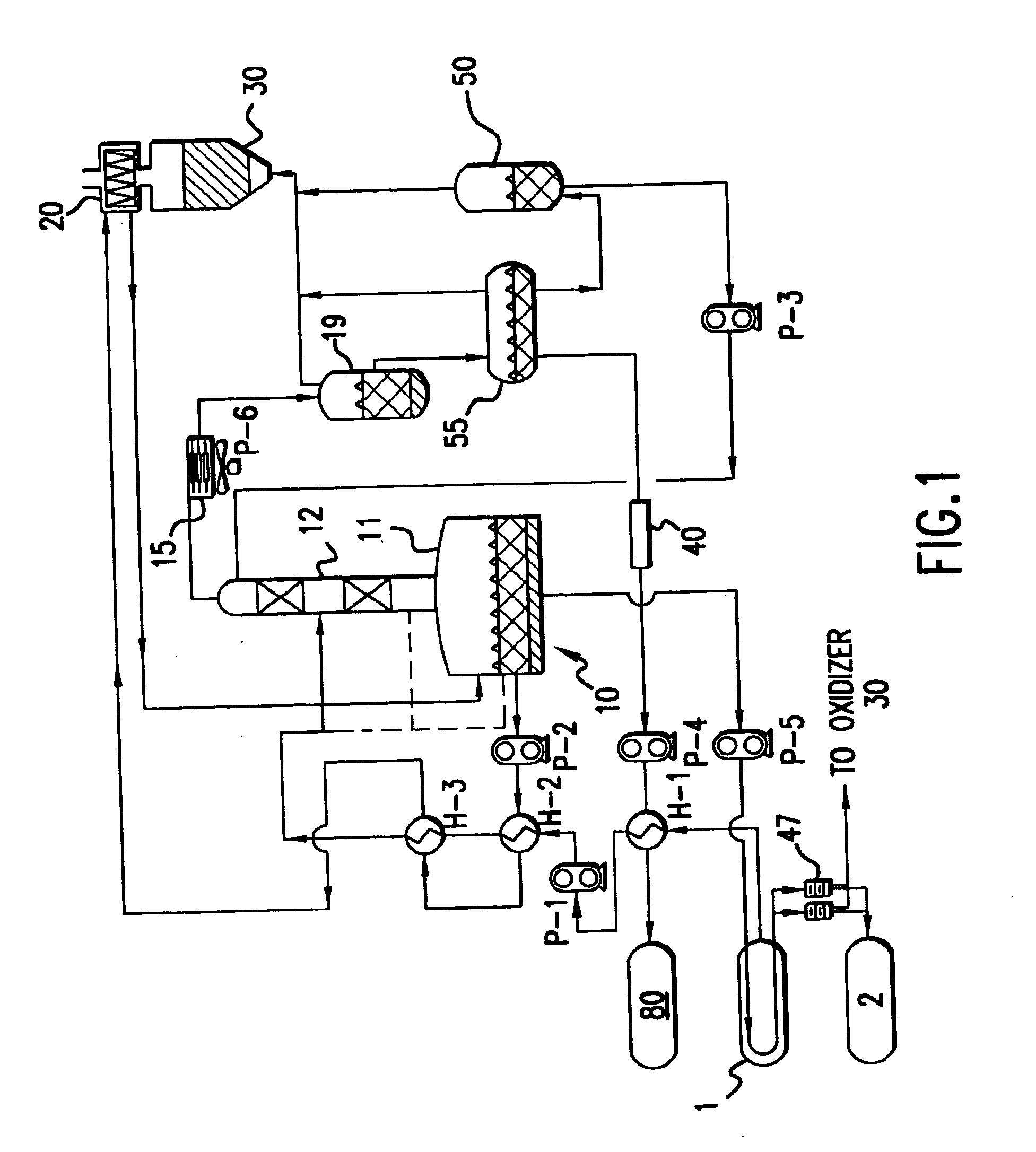

[0037] 1. A flow microreactor (11.5 mm×400 mm) was used for all studies. As the flow rates of the feed material were low, we used N2 as the co-feed to feed tallow in the reactor. Similar techniques have been used in earlier similar type of work. This technique helped to distribute the feed material evenly as well as it prevents any thermal gradients in the reactor. FIG. 1 shows a simple schematic diagram of the reactor set up. [0038] Also, by varying the co-feed N2 flow, the residence time in the reactor could be varied. Residence time also was an important variable. [0039] Temperature was the major variable for this study with a thermal cracking over the temperature range 200-600° C. [0040] Several runs were carried out at 800° C. to determine the final pyrolysis gaseous products as well. The objective was to optimize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com