Color-coating line waste gas treatment and heat recovery method and system based on concentration rotating wheels and RTO (regenerative thermal oxidizer)

A technology for concentrating runners and waste gas treatment, which is applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of high-grade energy waste, large energy consumption, and discharge into the atmosphere, and achieves energy saving, electric energy saving, The effect of reducing business expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the description appropriate, simple and clear, the following will be described in conjunction with examples.

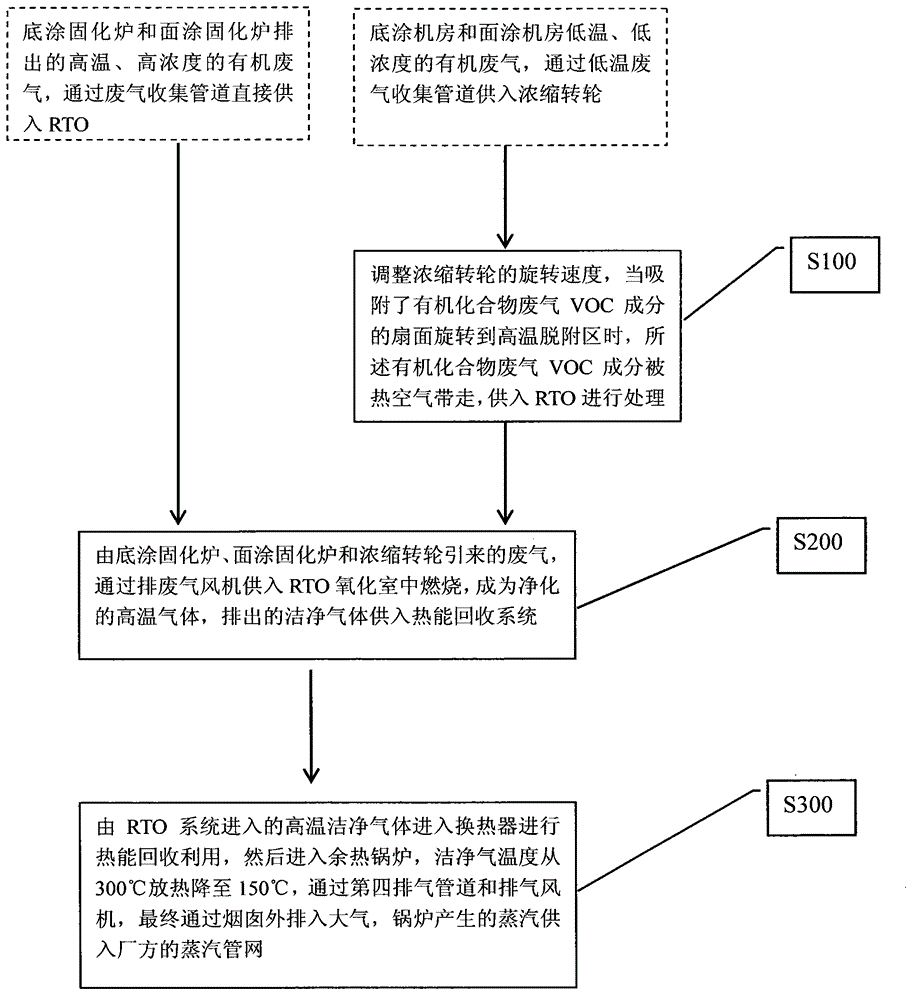

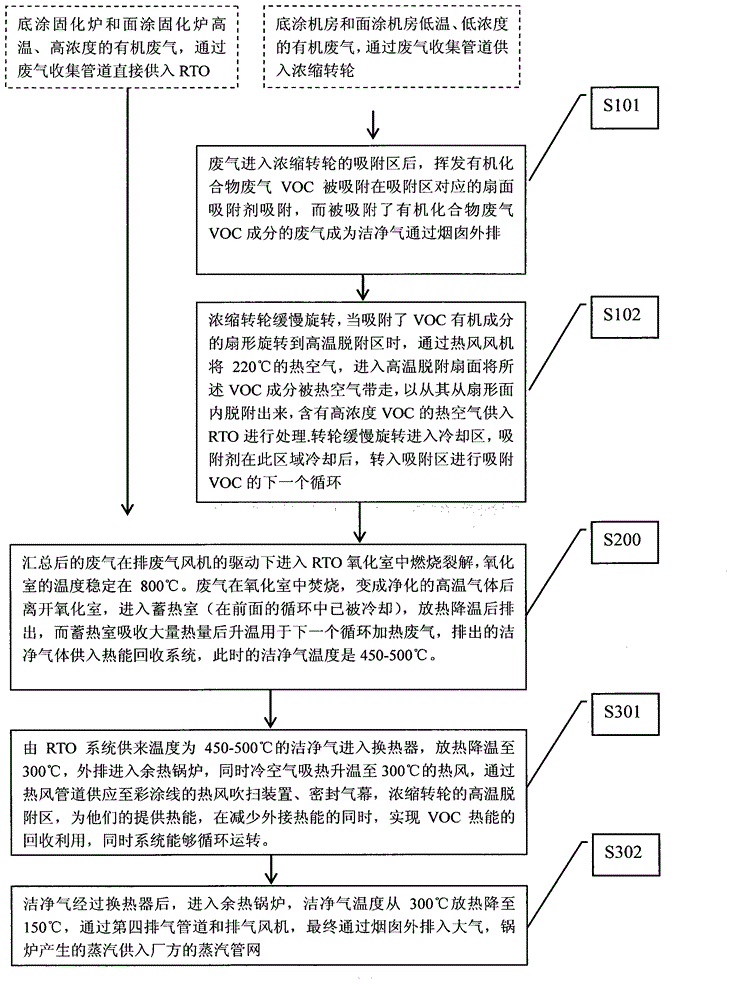

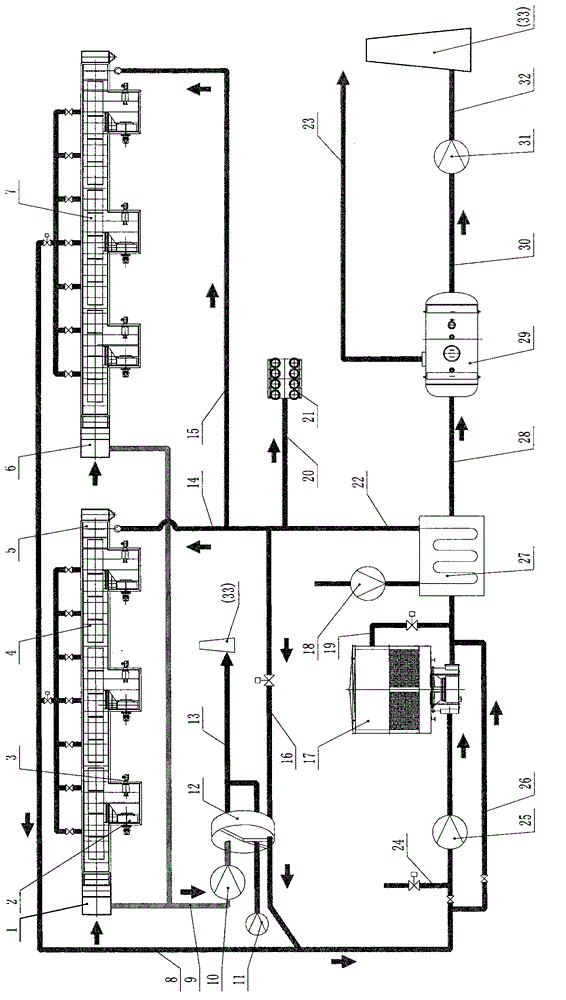

[0026] Reference attached figure 1 , using the enrichment wheel and regenerative incinerator (RTO) color coating production line exhaust gas treatment and waste heat utilization method, the low-temperature and low-concentration volatile organic compound exhaust gas discharged from the base coating machine room (1) and the top coating machine room (6) , into the concentration runner (12) through the low-temperature exhaust gas collection pipe (9). These low-temperature and low-concentration volatile organic compound waste gases are sent to the adsorption zone of the concentration runner (12), so that the VOC components in the waste gas are adsorbed by the adsorbent on the fan surface corresponding to the adsorption zone. The purified waste gas is converted into clean gas that meets emission requirements. Finally, they are discharged outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com