Waste gas treatment method and system of coating workshop based on concentrated runner and RTO (regenerative thermal oxidizer)

A technology for concentrating exhaust gas from runners and workshops, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as human health hazards, toxicity, and depletion of the high-altitude ozone layer, and achieve the goal of reducing the processing air volume and increasing the concentration of organic solvents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

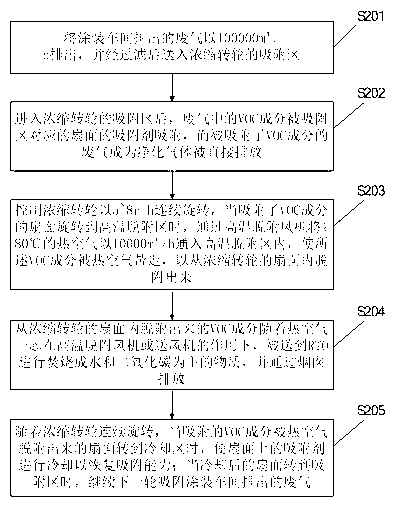

[0030] An embodiment of the present invention provides a paint shop exhaust gas treatment method based on a concentration wheel and an RTO, which is suitable for waste gas treatment including a concentration wheel and an RTO. The concentration wheel at least includes an adsorption zone and a high-temperature desorption zone. Such as figure 1 As shown, the method includes:

[0031] Step S101: Filter the exhaust gas discharged from the painting workshop and send it to the adsorption area of the concentration runner, so that the VOC components in the exhaust gas are adsorbed by the adsorbent on the fan surface corresponding to the adsorption area;

[0032] Specifically, in this embodiment, the exhaust gas discharged from the painting workshop is a high-volume exhaust gas containing low-concentration VOC. The flow rate of the exhaust gas is controlled, and the exhaust gas is first drawn to the front of the runner by the exhaust fan of the spray booth. After filtering (removing ...

Embodiment 2

[0038] The embodiment of the present invention provides a paint shop exhaust gas treatment method based on the concentration runner and RTO, which is suitable for exhaust gas treatment including the concentration runner and RTO. The concentration runner at least includes an adsorption zone, a high temperature desorption zone and a cooling zone. Area. Such as figure 2 As shown, the method includes:

[0039] S201: Discharge the exhaust gas from the painting workshop at 100,000m3 / h, and send it to the adsorption area of the concentration runner after being filtered;

[0040] Specifically, in this embodiment, the exhaust gas discharged from the painting workshop is a high-volume exhaust gas containing low-concentration VOCs. After being pumped by the exhaust fan of the spray booth to the filter device in front of the runner for filtering (removing certain impurities); then, under the action of the air supply fan, the waste gas containing low concentration VOC is sent to the a...

Embodiment 3

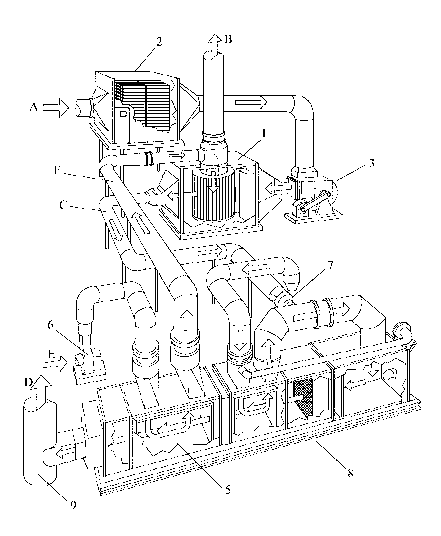

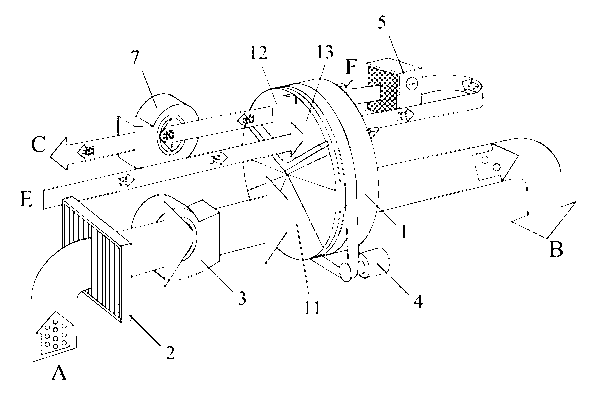

[0052] An embodiment of the present invention provides a paint shop exhaust gas treatment system based on a concentrated runner and an RTO, such as image 3 As shown, the system includes a concentration runner 1, a filter device 2, a low-concentration exhaust gas blower 3, a drive motor 4, a heat source 5, a fresh air blower 6, a high-concentration waste gas blower 7, and an RTO (regenerative thermal incinerator) 8 and chimney 9.

[0053] Below, combine Figure 4 , to introduce the working process of the paint shop exhaust gas treatment system in this embodiment.

[0054] The exhaust gas (exhaust gas with large air volume and low concentration of VOC) A discharged from the painting workshop is discharged at a certain flow rate (for example, at a flow rate of 100000m3 / h), and the exhaust gas is first discharged by the exhaust fan of the spray booth (not shown in the figure) (shown) is pumped to the filter device 2 in front of the runner to filter (remove certain impurities); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com