Method for preparing salidroside

A technology of salidroside and Rhodiola grandiflora, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problem of small amount of preparation by high-performance liquid chromatography, which is not suitable for industrialized large-scale production, and rhodiola To solve the problems of low content of tianosin, to achieve the effect of simple purification and refining process, treatment of cardiovascular and cerebrovascular diseases, and improvement of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

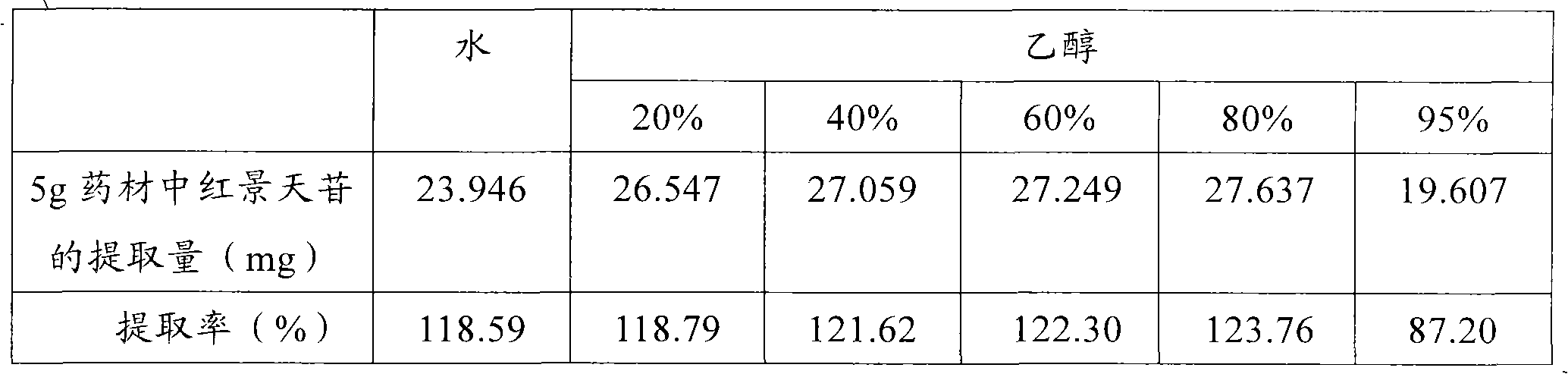

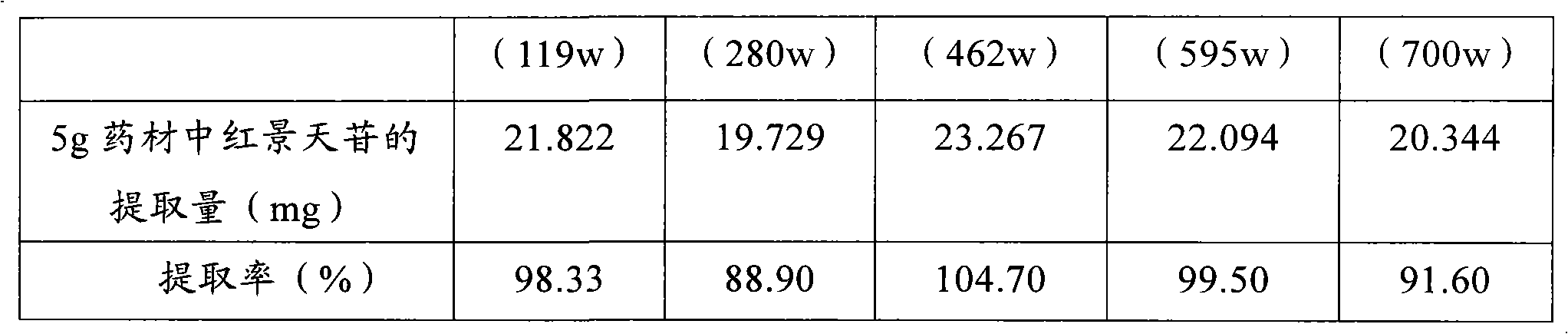

[0037] Example 1 Study on Extraction Technology of Rhodiola daflora

[0038] In this example, the extraction method, extraction solvent, raw material particle size, soaking time, and extraction conditions in the extraction process of Rhodiola daflora were studied respectively.

[0039] 1. Investigation of extraction method

[0040] Take 3 parts of Rhodiola grandiflora medicinal materials that have been passed through a 50-mesh sieve, each 10 g, and extract with hot reflux respectively (add 10 times the amount of water each time, heat at 100 ° C, extract 3 times, and extract 3 hours each time); ultrasonic Extraction (add 10 times the amount of water each time, ultrasonic frequency 45KHz, extract 3 times, extract 1 hour each time); microwave extraction (add 10 times the amount of water each time, microwave power 462w, extract 3 times, extract 1.5 minutes each time ); the extract is filtered, concentrated under reduced pressure to a relative density of about 1.00 (measured at 2...

Embodiment 2

[0081] Example 2 Study on Purification Process of Rhodiola daflora

[0082] When the ethanol content in the extract reaches 60% to 70%, except for tannins and resins, other impurities have basically been precipitated and removed. If ethanol is added in two times, the concentration will gradually increase, and finally reach 75% to 85%. The effect of removing impurities is better, so choose two alcohol precipitation methods to remove impurities.

[0083] 1. Investigation of the first alcohol precipitation process

[0084] The relative density of the extract, alcohol precipitation concentration, and alcohol precipitation time are the main factors affecting the purification process. For these three factors, we choose L 9 (3 4 ) Orthogonal experiments are optimized, and three conventional levels are selected in each factor to consider, and Table 8A is a factor level table:

[0085] Table 8A Alcohol precipitation process factor level table

[0086]

[0087] Take 9 parts of ...

Embodiment 3

[0119] Example 3 Research on the Refining Technology of Rhodiola daflora

[0120] In this example, the resin type and purification process conditions in the refining process of Rhodiola daflora were studied respectively.

[0121] 1. Selection of macroporous resin model

[0122] Take NK-2 (purchased from Tianjin Fine Chemical Co., Ltd.), SP825 (purchased from Japan Mitsubishi Chemical Industry), D101 (purchased from Japan Mitsubishi Chemical Industry), D301 (purchased from Japan Mitsubishi Chemical Industry), AB-8 (purchased from Japan Mitsubishi Chemical Industry Co., Ltd.), AB-8 (purchased from Japan Mitsubishi Chemical Industry Co., Ltd. factory), HP-20 (purchased from Mitsubishi Chemical), SP700 (purchased from Mitsubishi Chemical), S-8 (purchased from Anhui Samsung Resin Technology Co., Ltd.) 8 different models have been pretreated (pretreatment process: with Soak the newly purchased resin in 0.5BV of ethanol for 24 hours, then alternately elute with 3 times the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com