High pure attapulgite clay and preparation method

A technology of attapulgite and attapulgite, which is applied in the field of high-purity attapulgite and its preparation, can solve problems affecting the use effect and use range, and achieve the effect of simple and easy purification process, easy-to-obtain raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

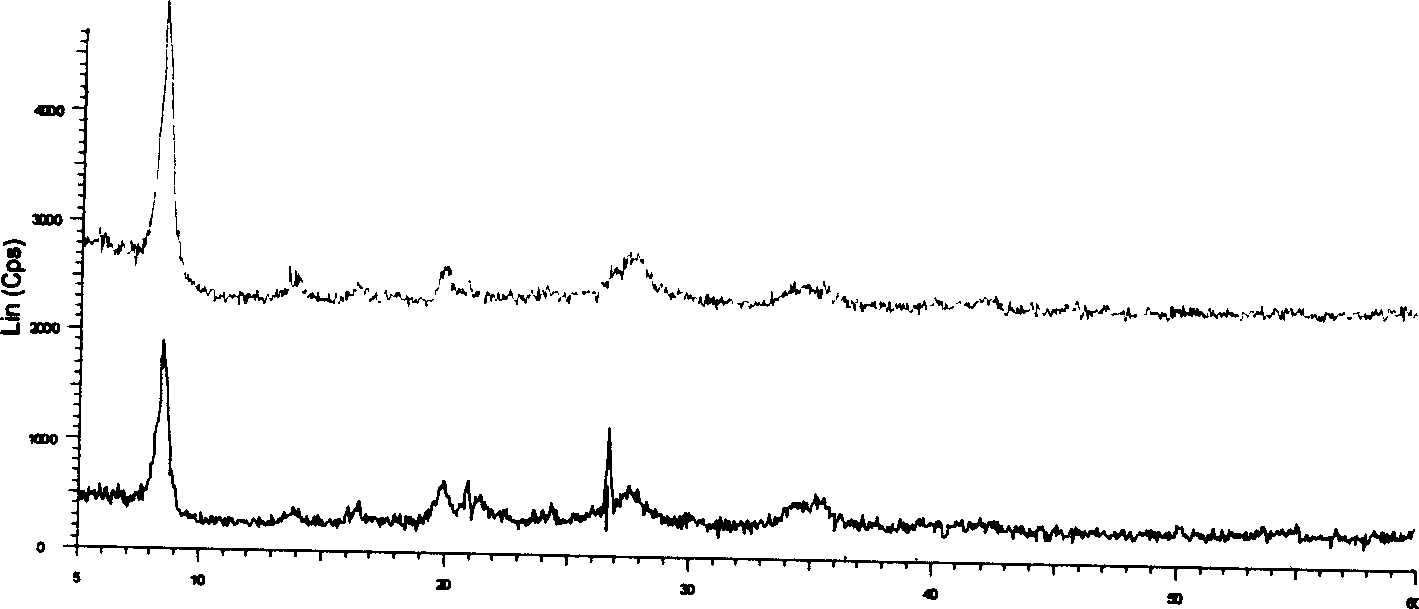

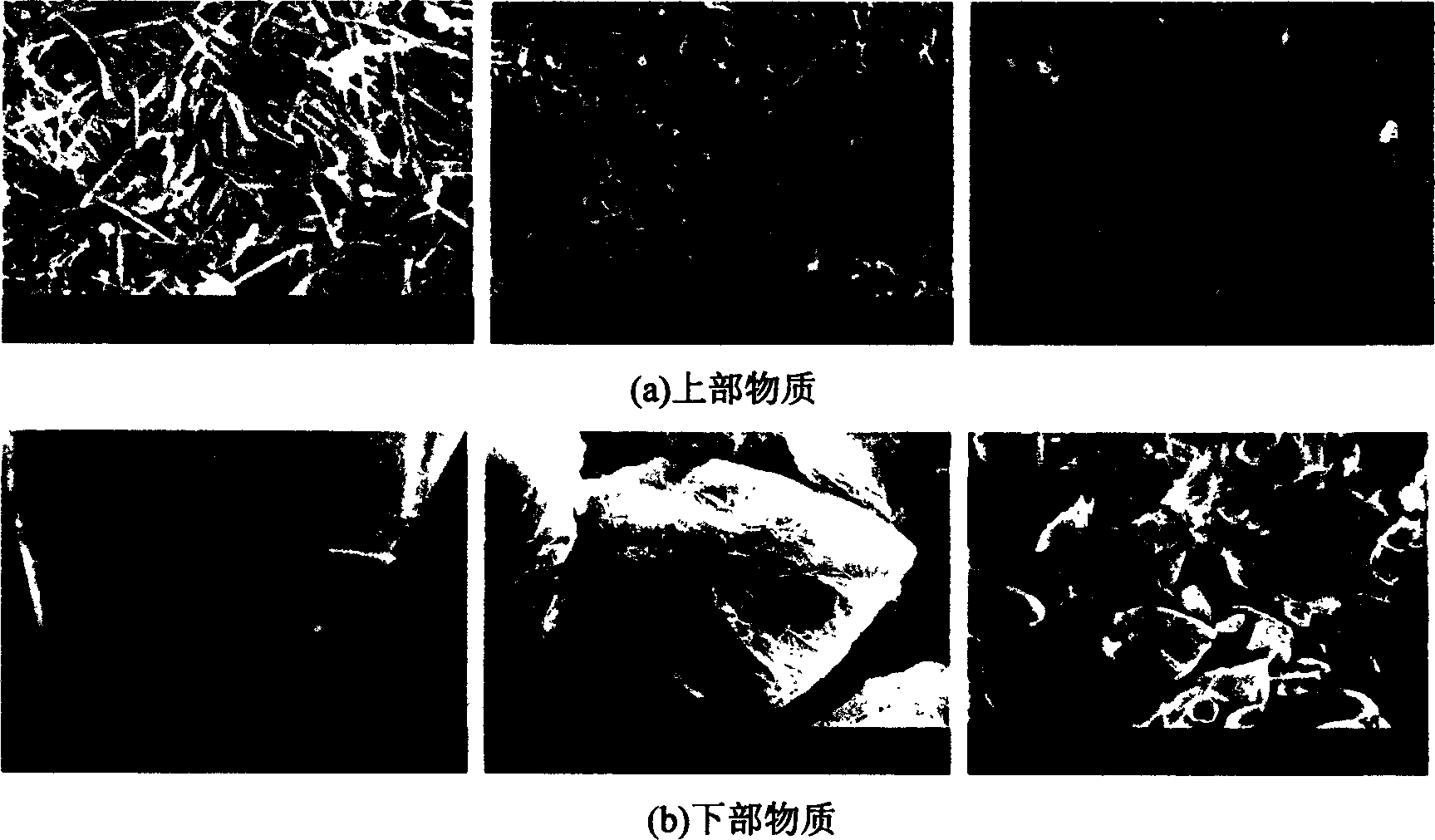

[0018] Example 1: gray-green attapulgite ore containing 17.2% of quartz and 83.8% of attapulgite, primary crushed to 200 mesh, added to 40°C, 1% homogeneous aqueous solution containing sodium polyphosphate at a ratio of 1:20, mechanically stirred for 20 minutes and mixed with After alternating 10min ultrasonic vibrations for 3 times each, stand still for 30min to produce an obvious off-white suspension and black precipitate layering, take out or pour out the upper suspension, and carry out vacuum spray drying at 80-100°C to obtain attapulgite with a content of 99.5% attapulgite particles with a whiteness of 87.

[0019] The x-diffraction and scanning electron microscope detection of attapulgite before and after purification are as follows: figure 1 with figure 2 shown.

example 2

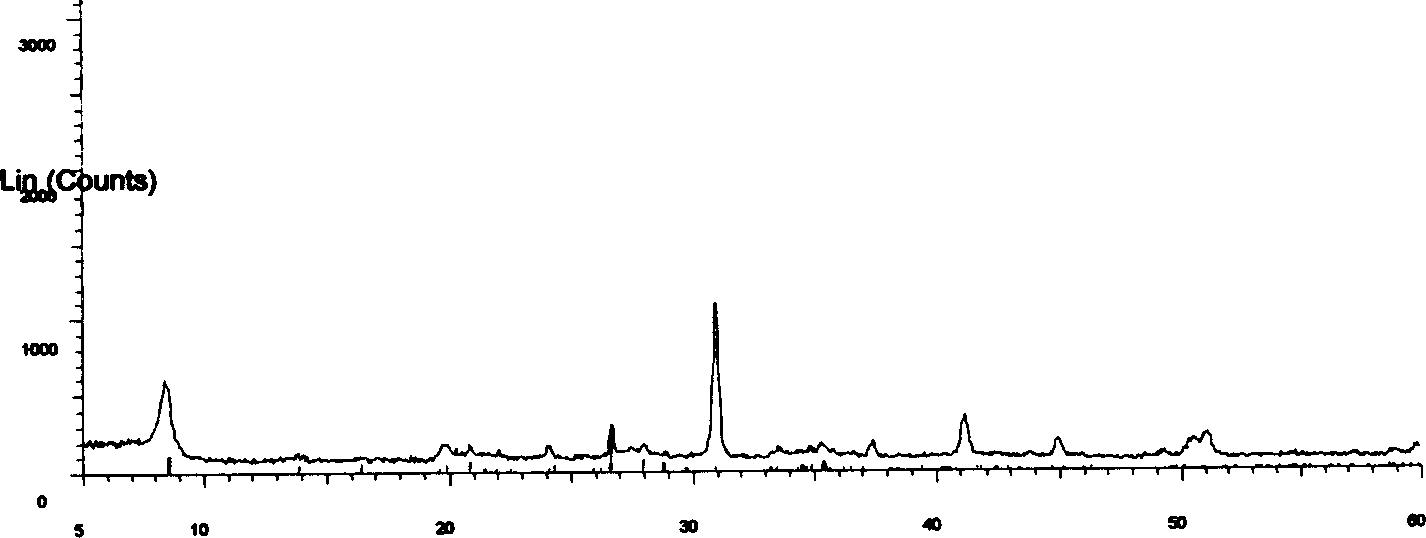

[0020] Example 2: The gray-white attapulgite ore containing dolomite and 47.5% of quartz is pre-filtered to 300 mesh, and added to a homogeneous aqueous solution containing 2.5% sodium silicate at 60°C at a ratio of 1:15, and mechanically stirred for 30 minutes and ultrasonically oscillated for 20 minutes. After 2 times, let it stand for 60 minutes, pour out the upper suspension, and carry out centrifugation to obtain attapulgite crystal slurry, and then vacuum freeze-dry at 40°C to obtain attapulgite with a content of attapulgite of 90% and a whiteness of 91. particles.

[0021] The x-diffraction and scanning electron microscope detection of attapulgite before and after purification are as follows: image 3 with Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com