Molecular sieve adsorption apparatus for high-humidity organic waste gas

A technology of organic waste gas and adsorption device, which is applied in the field of molecular sieves, and can solve problems such as ambient air pollution, low work efficiency, and low organic matter adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

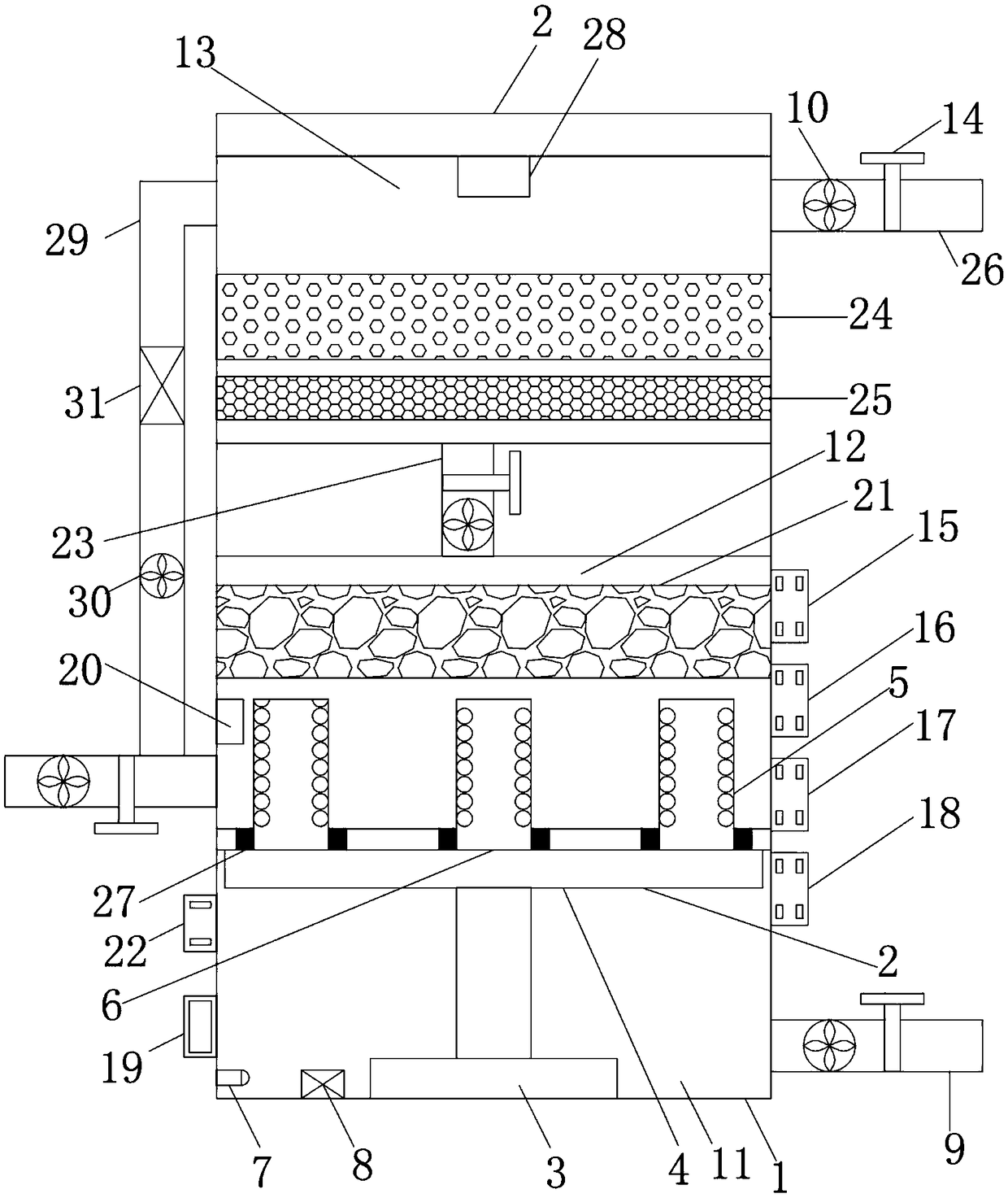

[0025] Such as figure 1 As shown, a molecular sieve adsorption device for high-humidity organic waste gas includes a waste gas purification cylinder 1, a sealing cover 2 is provided on the top surface of the waste gas purification cylinder 1, and an air inlet is provided at the lower left end of the waste gas purification cylinder 1 , The upper right end of the exhaust gas purification cylinder 1 is provided with an air outlet.

[0026] The exhaust gas purification cylinder 1 is provided with a dehydration chamber 11, a dehumidification chamber 12, and a purification chamber 13 in order from bottom to top; the dehydration chamber 11 is used for dehydration of silica gel; the dehumidification chamber 12 is used to remove moisture in the exhaust gas; the purification chamber 13 is used for further filtering exhaust gas.

[0027] The inner bottom surface of the dehydration chamber 11 is provided with an electric telescopic cylinder 3, the telescopic rod of the electric telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com