Method for determining melting behavior and melting point of slag-like material

A technology of melting point measurement and behavior, which is applied in the field of metallurgical slag material detection, can solve the problems of low accuracy, difficult control of the stability of the measurement conditions of the molten steel slag method, and high measurement costs, so as to achieve accurate test results and dynamic testing process intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] Example 1 Observation of melting behavior of blast furnace slag and accurate determination of melting point

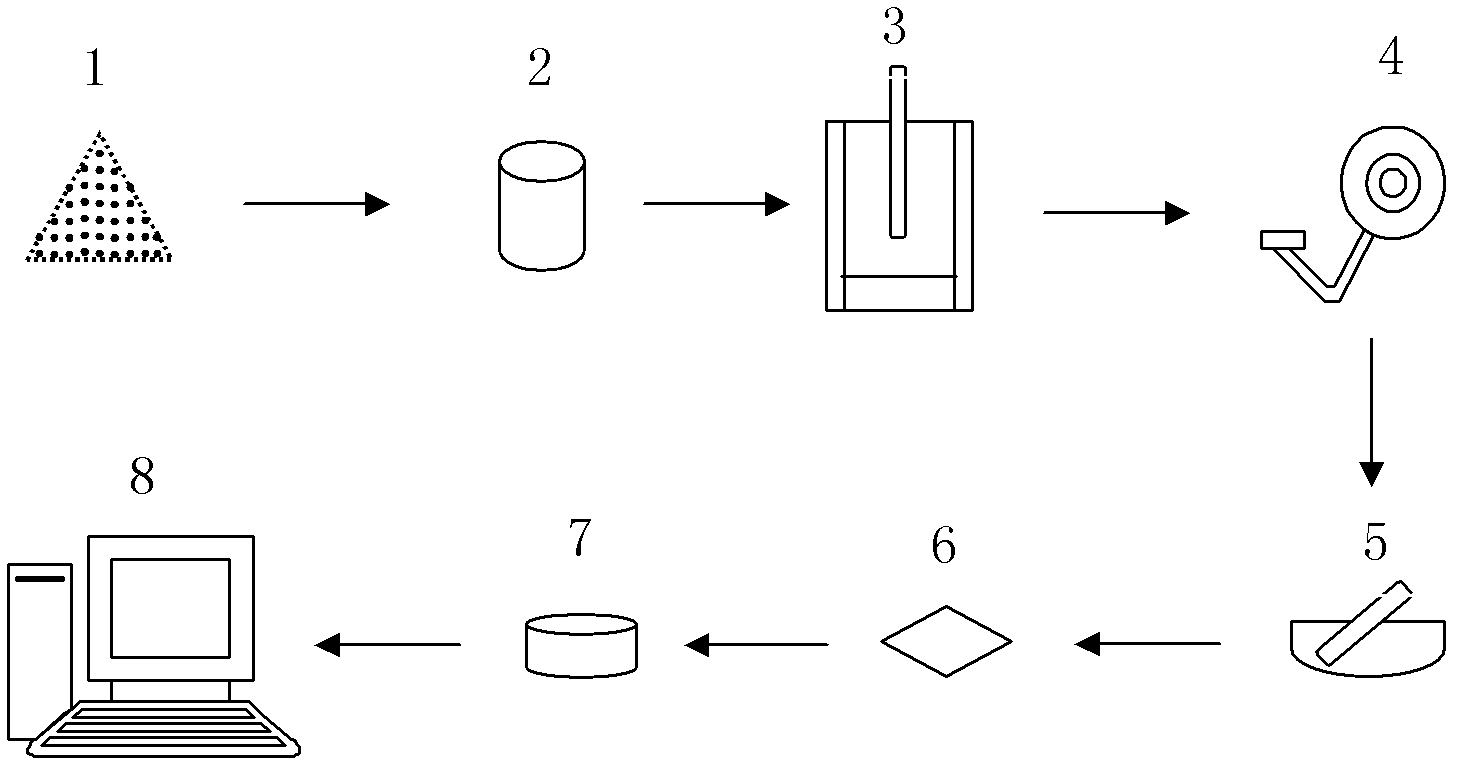

[0051] The present invention is applied in the observation of blast furnace slag melting behavior and the determination of melting point, and the specific steps are as follows:

[0052] 1. Slag sample preparation. Burn blast furnace slag to glassy slag and water quench, then grind into 100 mesh slag powder.

[0053] 2. Slag sample forming. With the help of dextrin and anhydrous filter paper, press and fix the powder sample on the platinum sheet to shape the slag sample.

[0054] 3. High temperature laser sample loading. Place the platinum sheet with the molded slag sample on the Al 2 o 3 After the bottom of the crucible is put into the high-temperature metallographic heating furnace of the high-temperature laser confocal microscope.

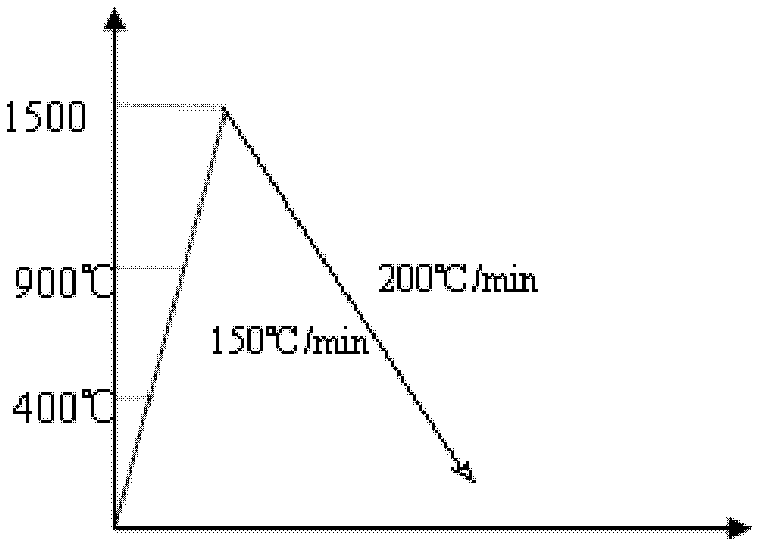

[0055] 4. Experimental program setting. Set up the experimental program for the temperature rise of blast furnace slag (se...

example 2

[0062] Example 2 Observation of Mold Flux Melting Behavior and Accurate Determination of Melting Point

[0063] The present invention is applied in the observation of melting behavior of mold flux and determination of melting point, and the specific steps are as follows:

[0064] 1. Slag sample preparation. Burn the mold slag to glassy slag and quench it with water, then grind it into 150 mesh slag powder.

[0065] 2. Slag sample forming. With the help of dextrin and anhydrous filter paper, press and fix the powder sample on the platinum sheet to shape the slag sample.

[0066] 3. High temperature laser sample loading. Place the platinum sheet with the molded slag sample on the Al 2 o 3 After the bottom of the crucible is put into the high-temperature metallographic heating furnace of the high-temperature laser confocal microscope.

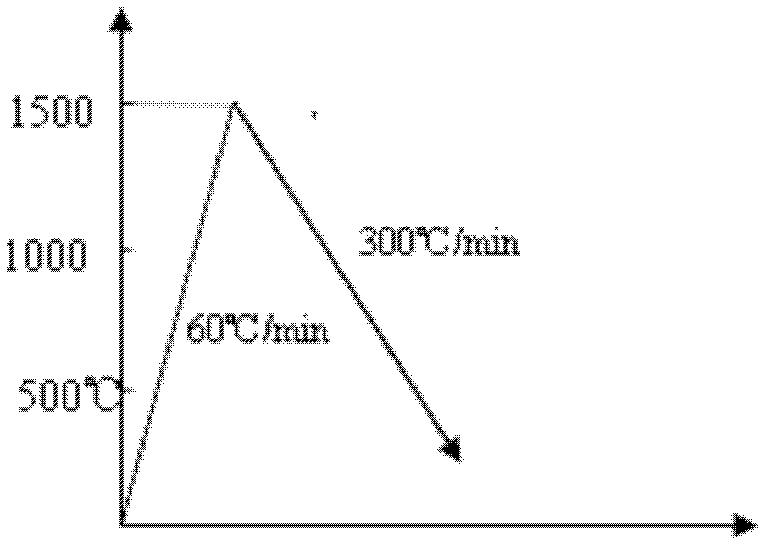

[0067] 4. Experimental program setting. Set up the temperature rise experiment program of mold flux (see image 3 ), after vacuuming in A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com