Combined cooling power generation composite system based on supercritical organic Rankine cycle

A Rankine cycle and composite system technology, which is applied in the field of combined cooling and power generation composite system, can solve the problems of increased energy loss, increased system operating cost and instability, and reduced energy utilization rate, so as to reduce heat exchange load and ensure Safe and efficient operation, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

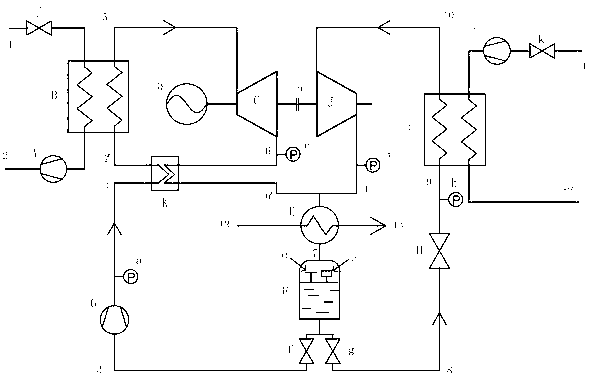

[0012] The following in conjunction with the accompanying drawings in the description figure 1 The specific implementation of the present invention will be described in detail.

[0013] The present invention mainly consists of a smoke exhaust fan A, a heat absorber B, an expander C, a generator D, a condenser E, a liquid storage tank F, a working medium pump G, a throttle valve H, an evaporator I, a compressor J, It is composed of regenerator K, refrigerant water pump L, solenoid valve, connecting pipes and monitoring equipment.

[0014] Working process of the present invention is as follows:

[0015] Part of the saturated liquid organic working fluid from the storage tank F enters the working medium pump G through the first solenoid valve f, and part of it flows to the throttle valve H through the second solenoid valve g. By adjusting the electromagnetic valve to control the flow rate of the working fluid, it can assist in adjusting the share of power generation and cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com