Patents

Literature

31results about How to "Reduce heat transfer load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

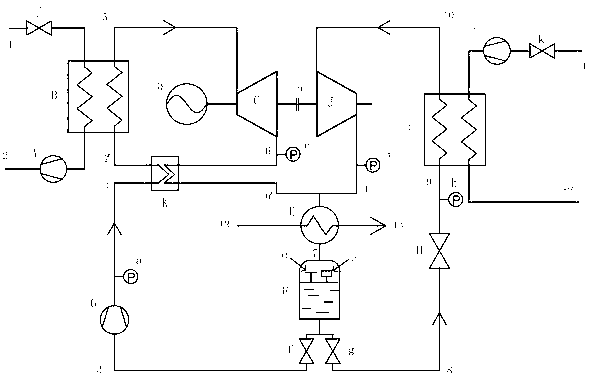

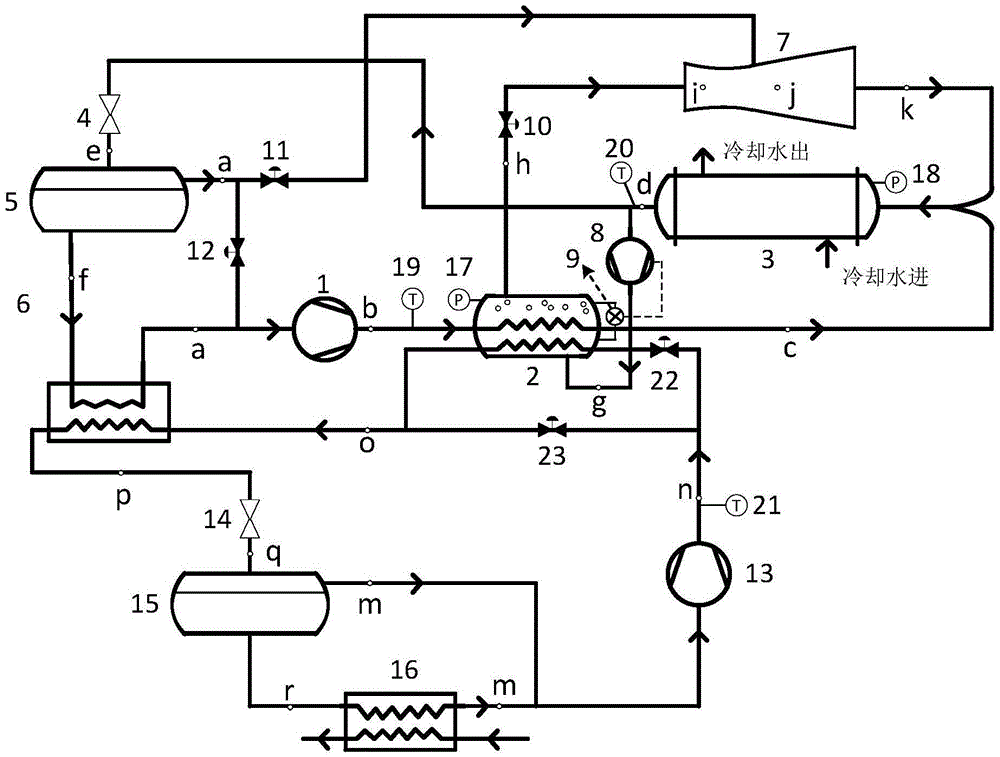

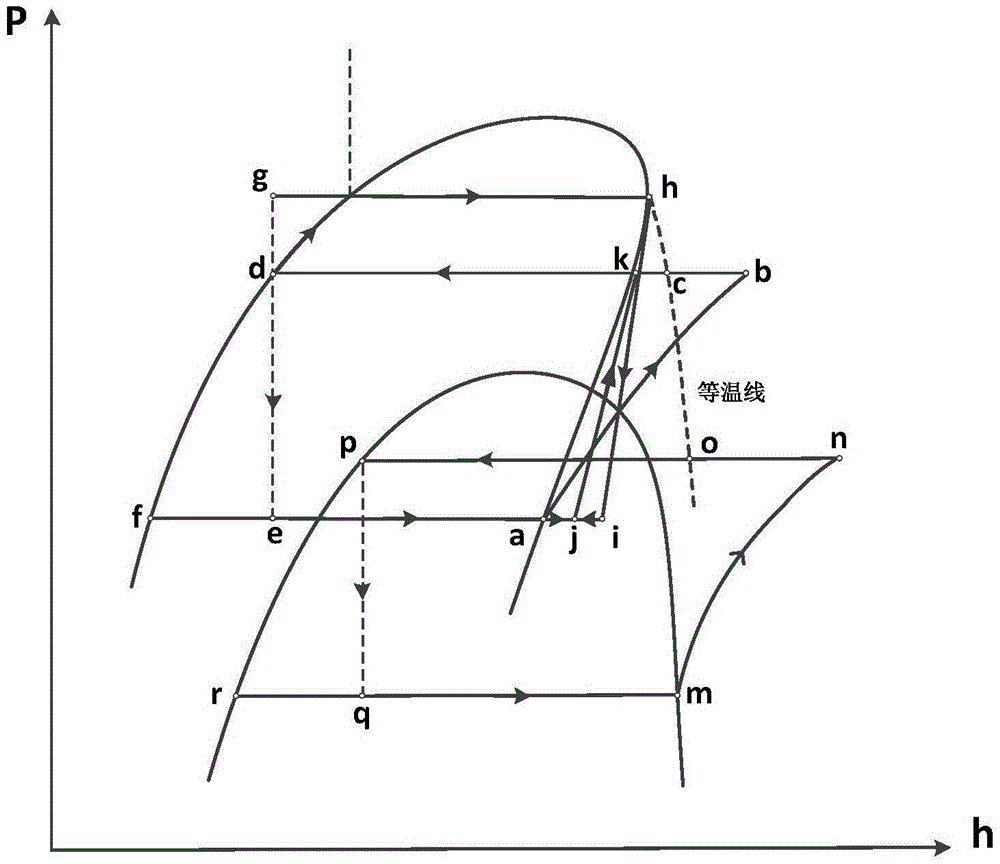

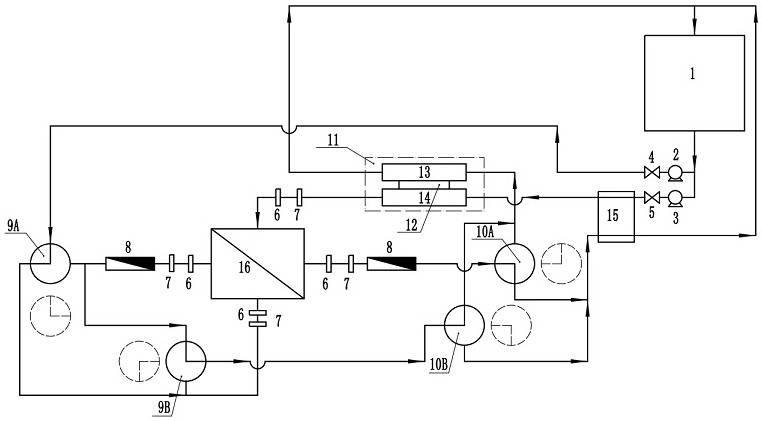

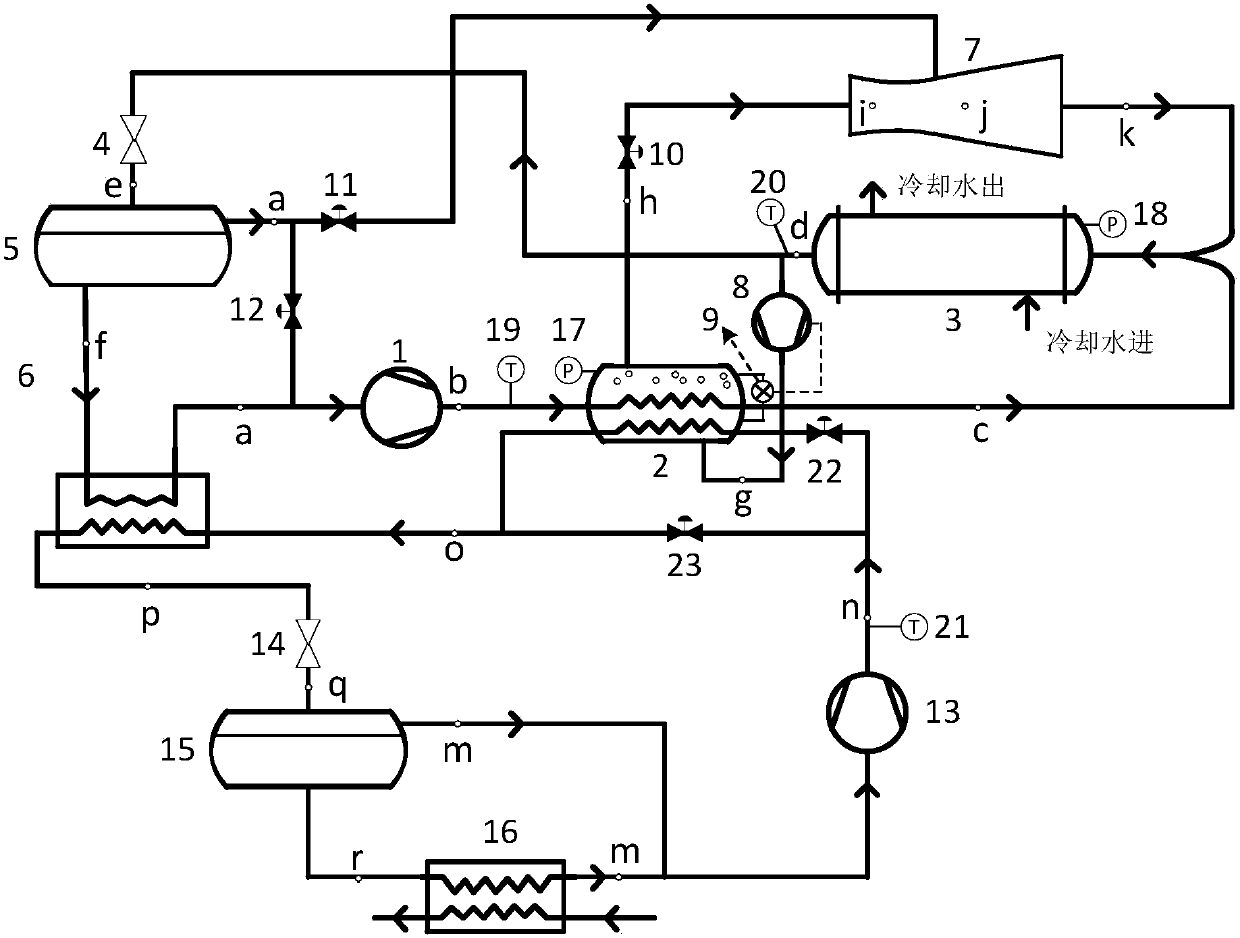

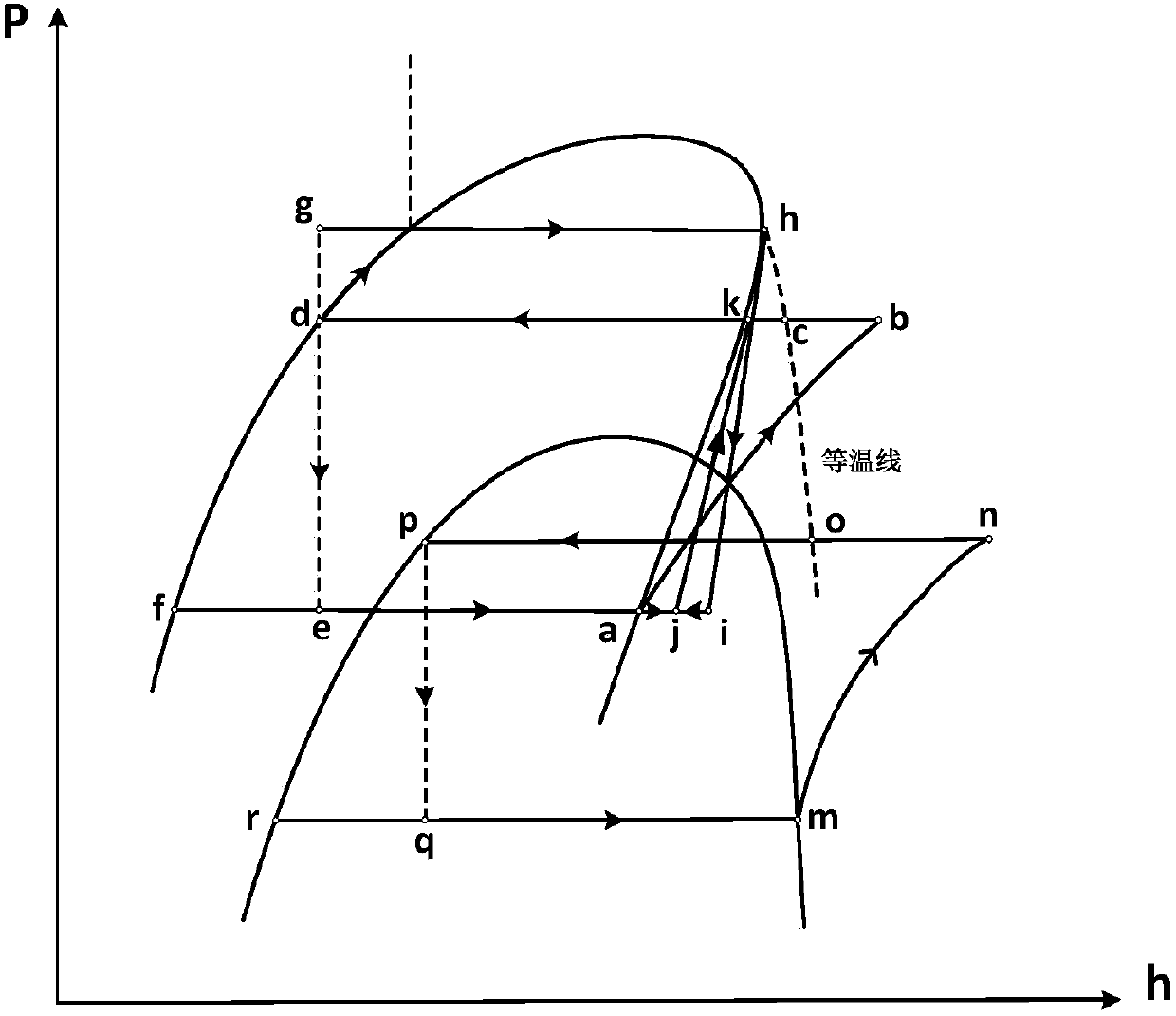

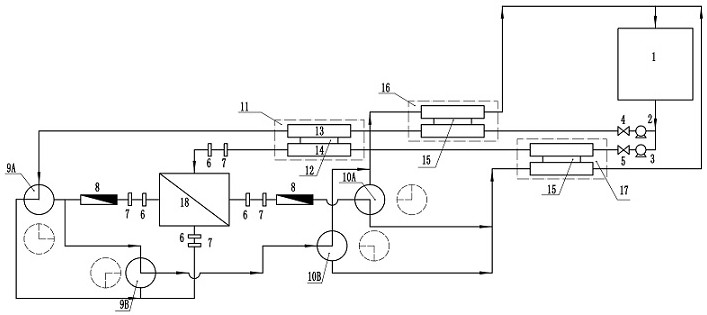

Combined cooling power generation composite system based on supercritical organic Rankine cycle

InactiveCN103195526AGuaranteed uptimeGuaranteed safe operationCompression machines with non-reversible cycleSteam useElectricityOrganic Rankine cycle

The invention provides a combined cooling power generation composite system based on a supercritical organic Rankine cycle and belongs to the field of industrial energy conservation. An expansion machine, a power generator and a steam compressing cold cycling compressor of the Rankine cycle are connected coaxially, same organic working medium is used to be simultaneously cooled in a condenser, and a steam compressing refrigerating cycle is coupled effectively on the basis of basic organic Rankine cycle. In addition, supercritical pressure is used to allow heat rising of organic working medium in a heat absorber to be well matched with temperature changing curve of a heat source, system irreversible loss is further lowered, and waste heat recycling rate is improved. Industrial smoke water heat or other water heat sources are used as driving force, combined cooling power generation is performed by taking refrigerating as priority, refrigerating is not performed by using smoke waste heat for power generation and using power for refrigerating, and accordingly loss caused by energy conversion is reduced. Cooling amount and power output amount can be flexibly adjusted according to cooling amount requirements.

Owner:CHONGQING UNIV

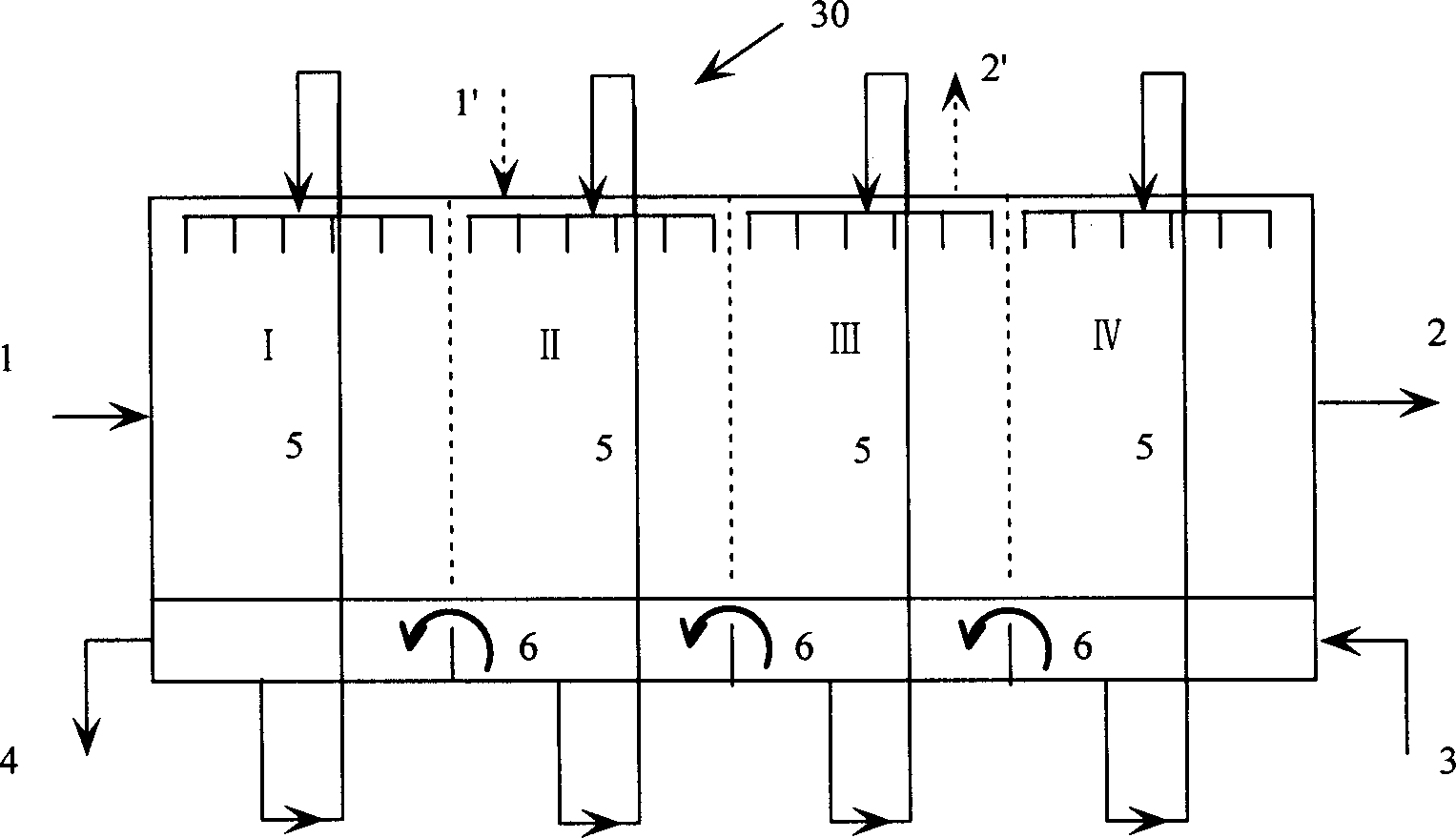

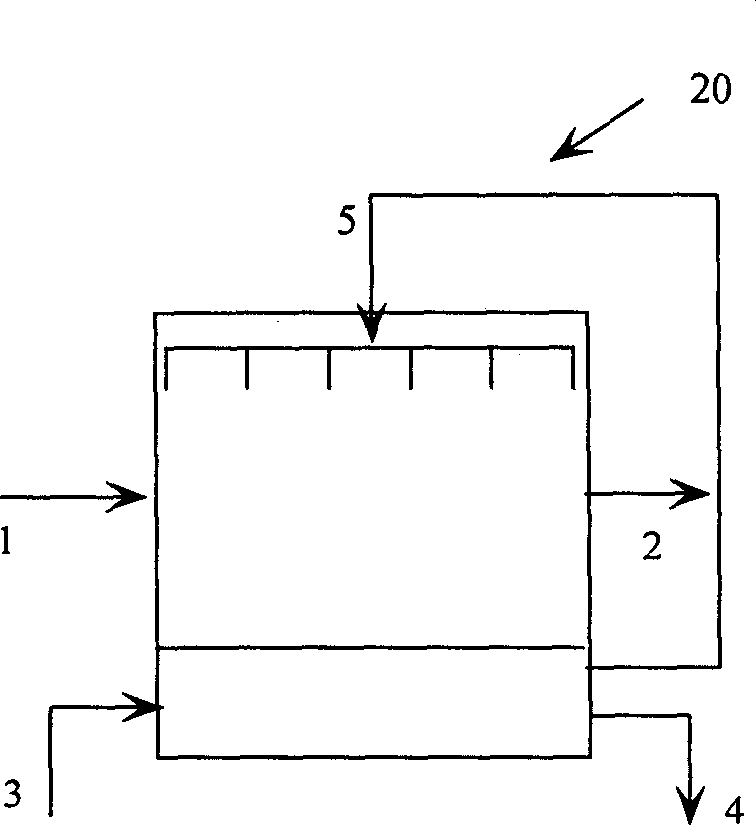

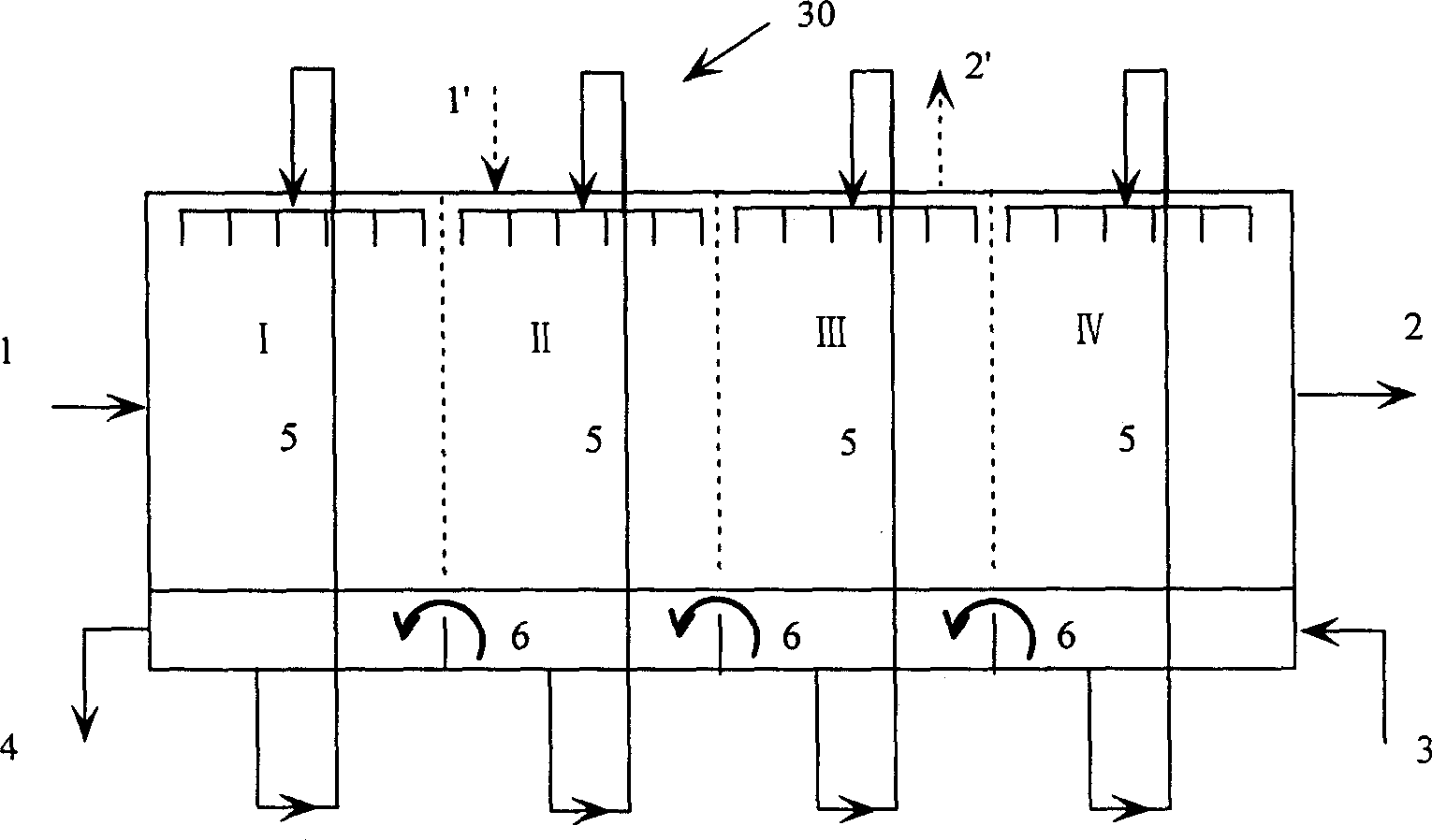

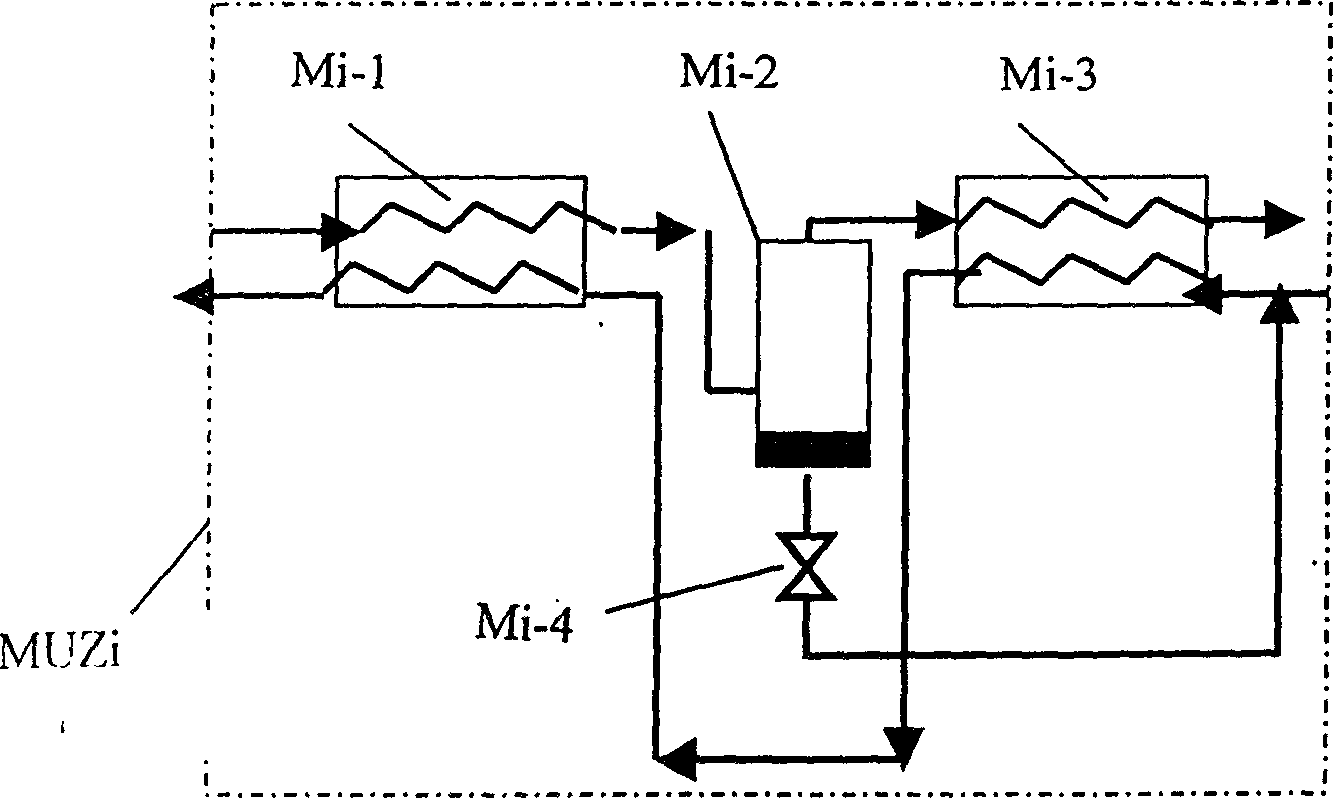

Multistage method for dehumidifying liquid

InactiveCN1415909ALower dew pointRegulate drynessLighting and heating apparatusDispersed particle separationLow densityAir conditioning

This invention relates to a multistage solution dehumidification method characterizing the solution dehumidification is classified into two or more stages, each stage solution circulates independently with different concentration, yet single-way transition exists between stages from high to low density and the most condensed solution stage is supplemented a certain amount of solution from outside and the weak solution stage exhausts a certain amount of solution, then the being processed gas will be dried via stages. This invention utilizes various cooling and gas-liquid contact way flexiblely.

Owner:刘拴强

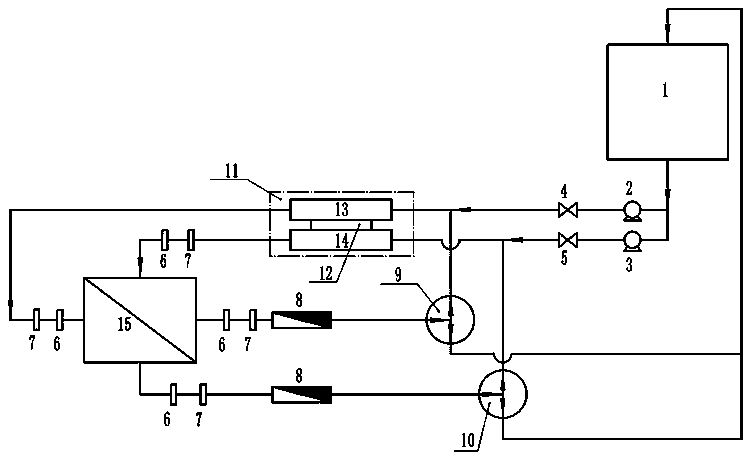

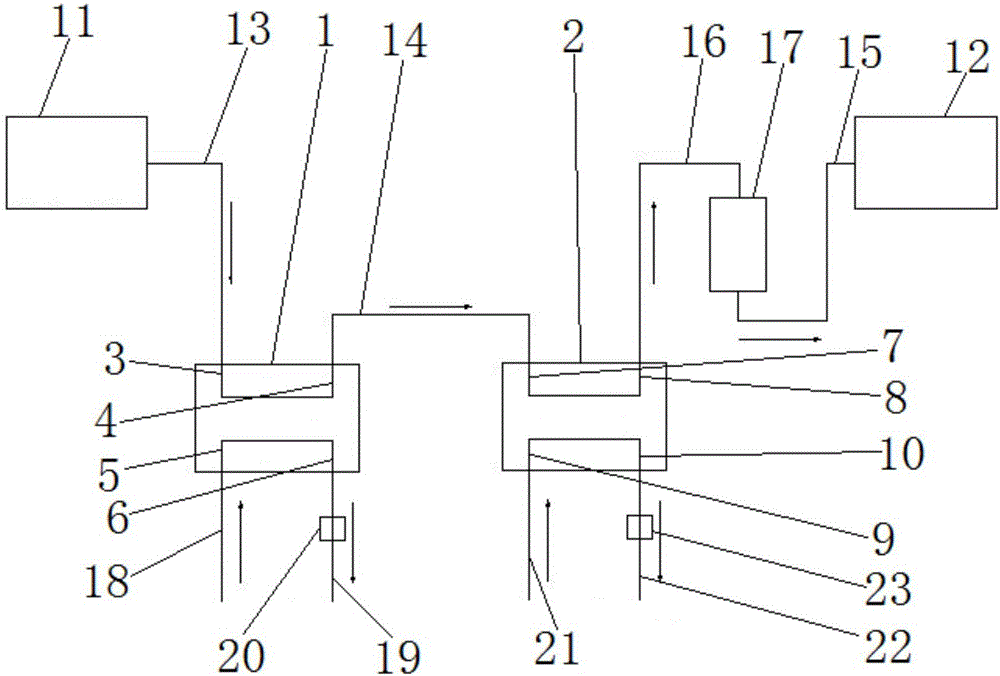

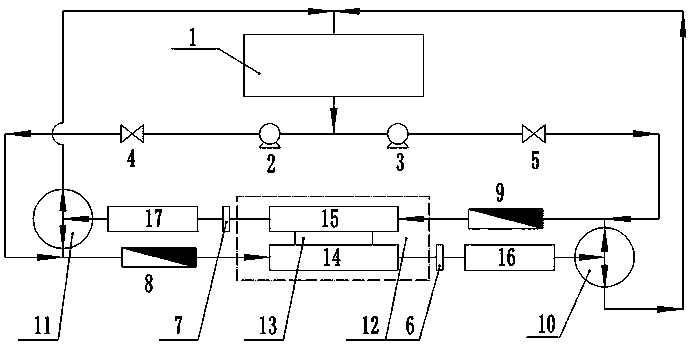

Desktop type self-water-supply heat exchanger performance testing device

InactiveCN109781782AAccuracy meetsRealize mixed cold and heat compensation heat exchangeMaterial heat developmentStructural/machines measurementExpansion tankSystem requirements

The invention provides a desktop type self-water-supply heat exchanger performance testing device based on a semiconductor heat pump. The semiconductor heat pump technology is utilized, the size is small, control is flexible, and the desktop system requirement is met; energy conservation is realized, especially when cold water and hot water are supplied at the same time, energy compensation is achieved, and cold and hot source energy is recycled; periodical water supply is realized, water supply and sewerage are not needed, the experiment is convenient and flexible, and the device is not limited by the positions of water supply and sewerage pipes; a heat exchanger type expansion water tank is adopted, a large-size cold and hot water tank is abandoned, the structure is compact, mixed cold and hot compensation heat exchange of cold and hot water is achieved, the environment heat exchange load is reduced, and water supplementing, pressure fixing and system gas discharging or excessive water containing are achieved. The device is flexible, convenient, compact in structure, water-saving, environment-friendly, energy-saving, capable of achieving thermal performance and resistance characteristics of a liquid-liquid heat exchanger, and widely suitable for experiment teaching and testing requirements of the heat exchanger.

Owner:QINGDAO UNIV

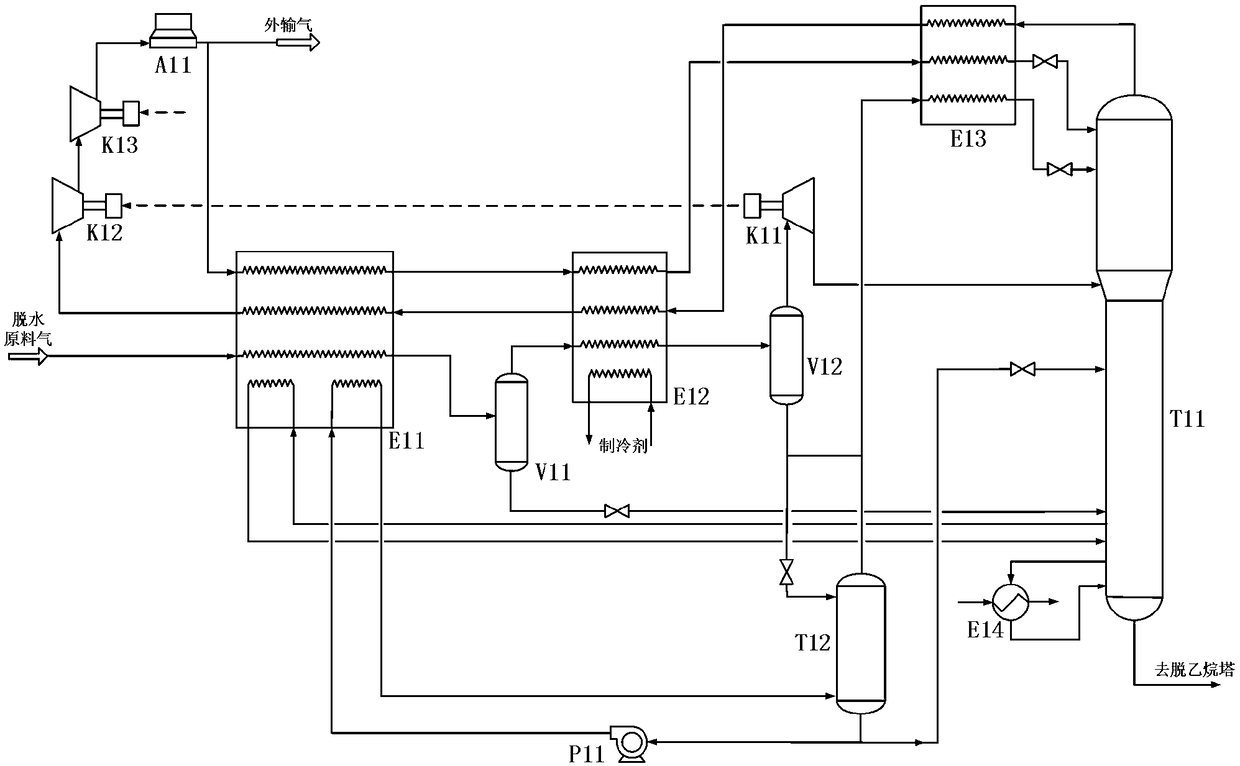

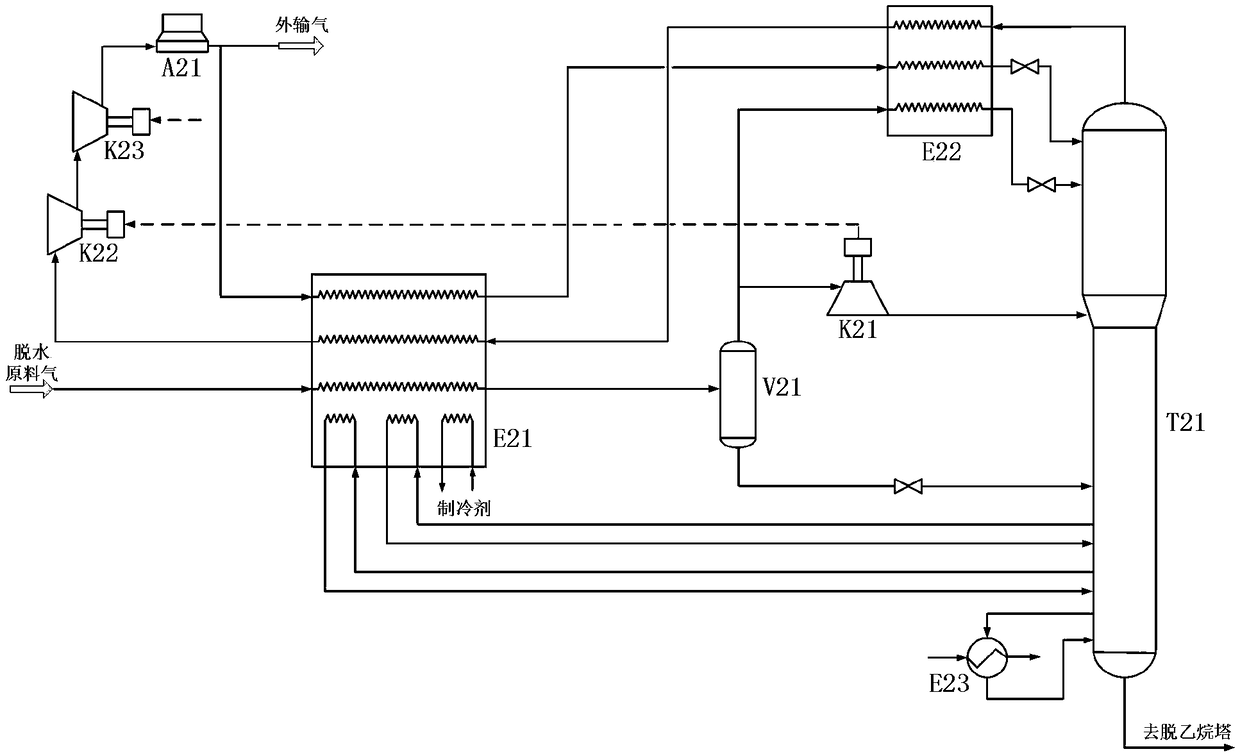

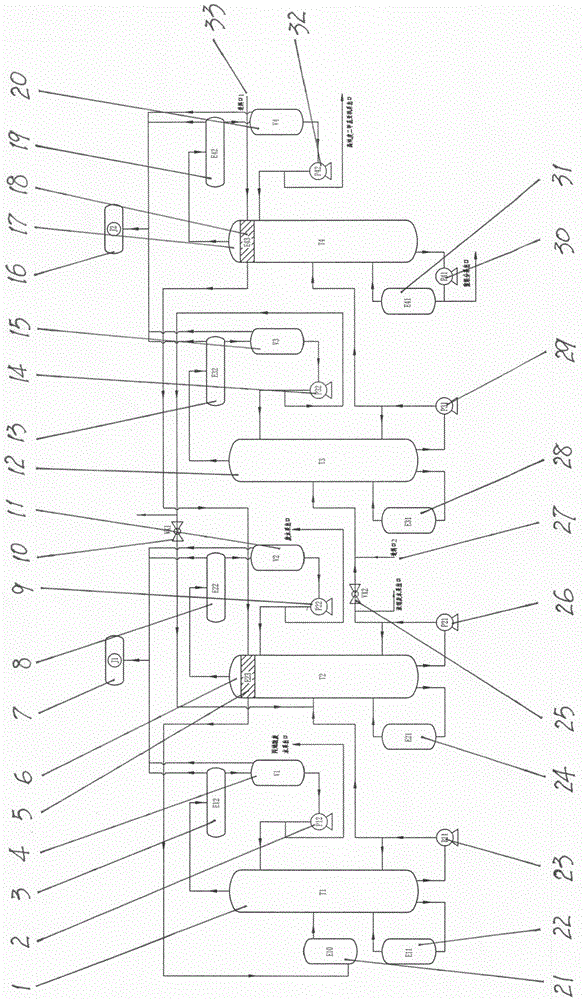

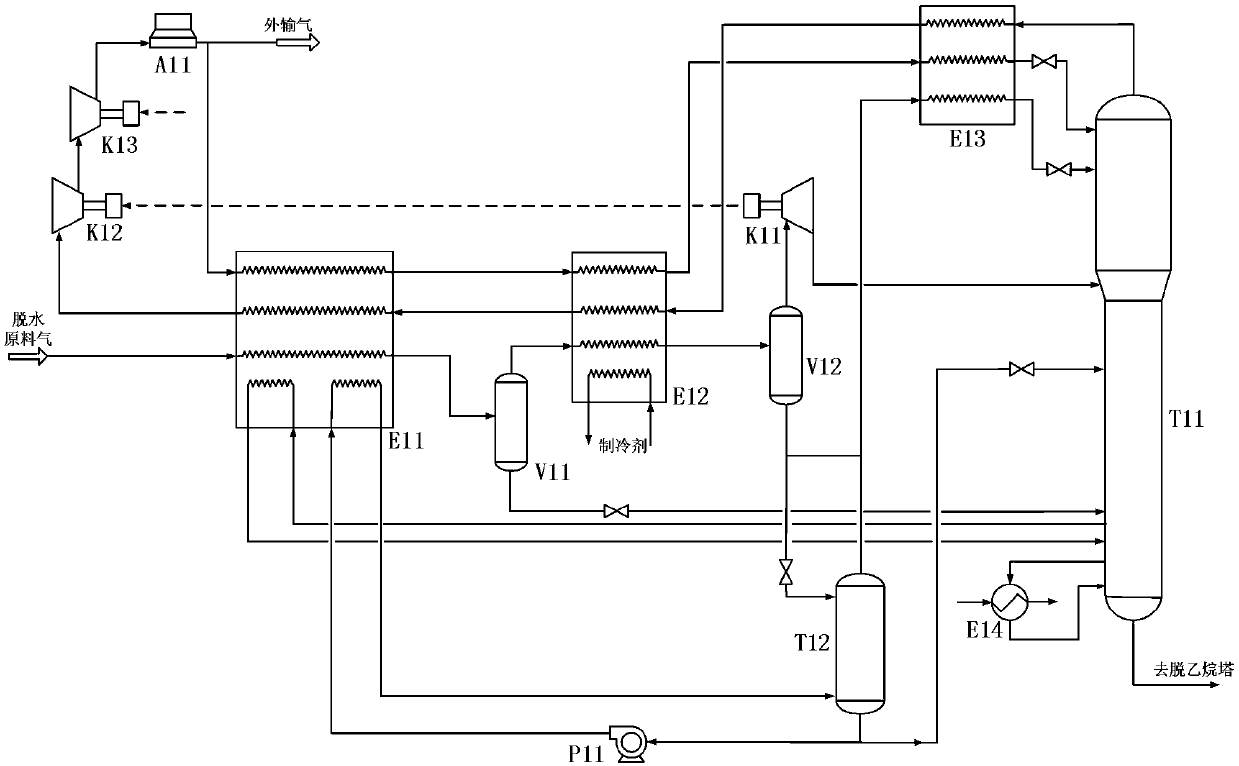

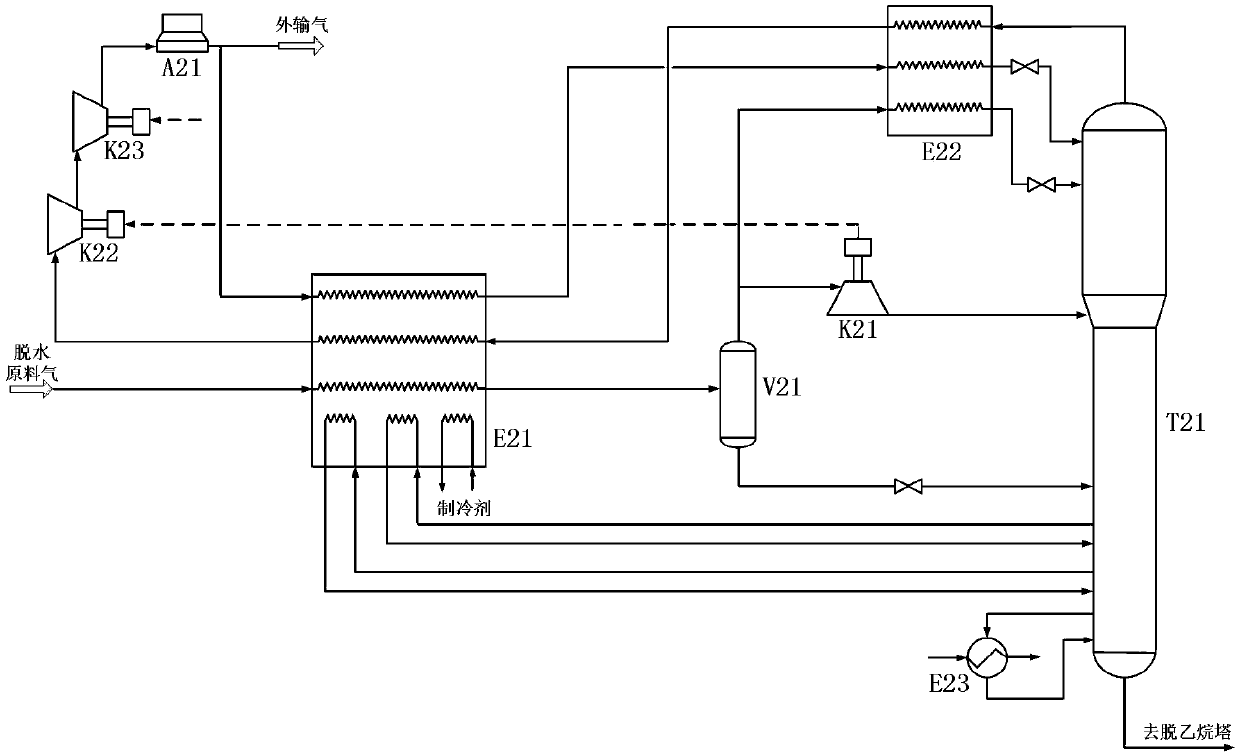

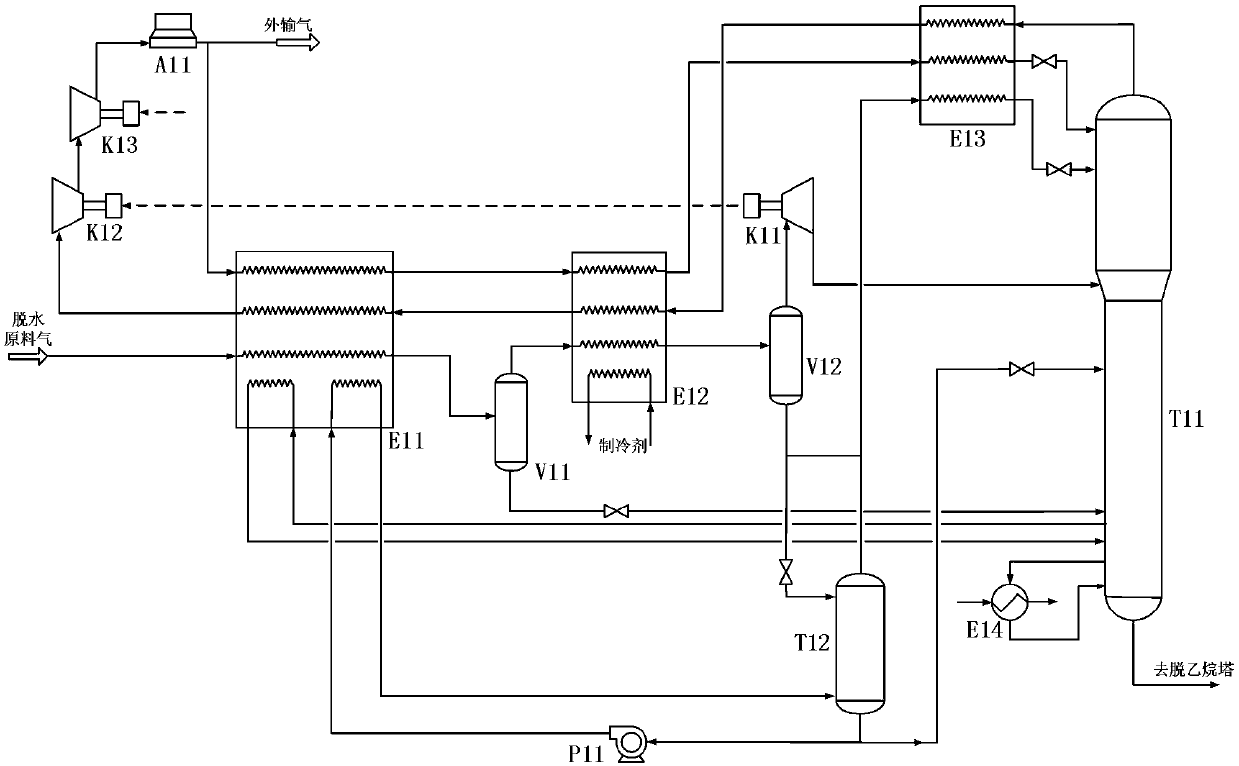

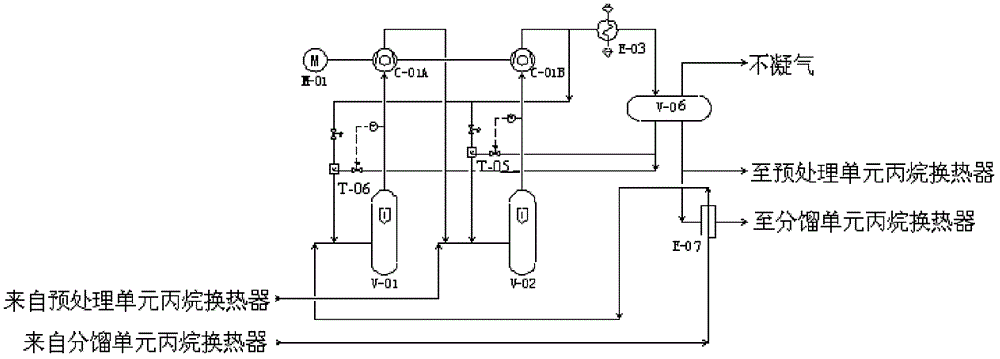

Ethane recovery method with absorption tower suitable for rich gas

ActiveCN108731380AHigh recovery rateGood absorption cooling effectSolidificationLiquefactionFractionationCooling effect

The invention discloses an ethane recovery method with an absorption tower suitable for rich gas. Raw material gas is cooled by a first cold box and then enters a separator for pre-separation; a gas phase separated by the separator enters a second cold box and is further cooled and then enters a low temperature separator; a gas phase separated by the low temperature separator totally enters the expansion end of a turbo-expander for expansion cooling, and then enters the middle-upper part of a demethanizer, a part of condensate of the bottom of the absorption tower is reheated in the first coldbox and is gasified in a large amount mode and then enters the bottom portion of the absorption tower, and the other part of the condensate is directly connected into the middle of the demethanizer;the gas phase of the top of the absorption tower is discharged and deep-cooled, and then is subjected to throttling and cooling to enter the upper portion of the demethanizer; the gas phase of the topof the demethanizer is subjected to heat transfer and heating and pressurization, and then transported outwards after cooled by an air cooler; and a condensate product at the bottom of the demethanizer enters subsequent fractionation processing units such as the demethanizer for processing. The tower overhead feed enriched with more methane can enable a better absorbing and cooling effect on theupper portion of the demethanizer, and the recovery rate of the ethane is improved.

Owner:SOUTHWEST PETROLEUM UNIV

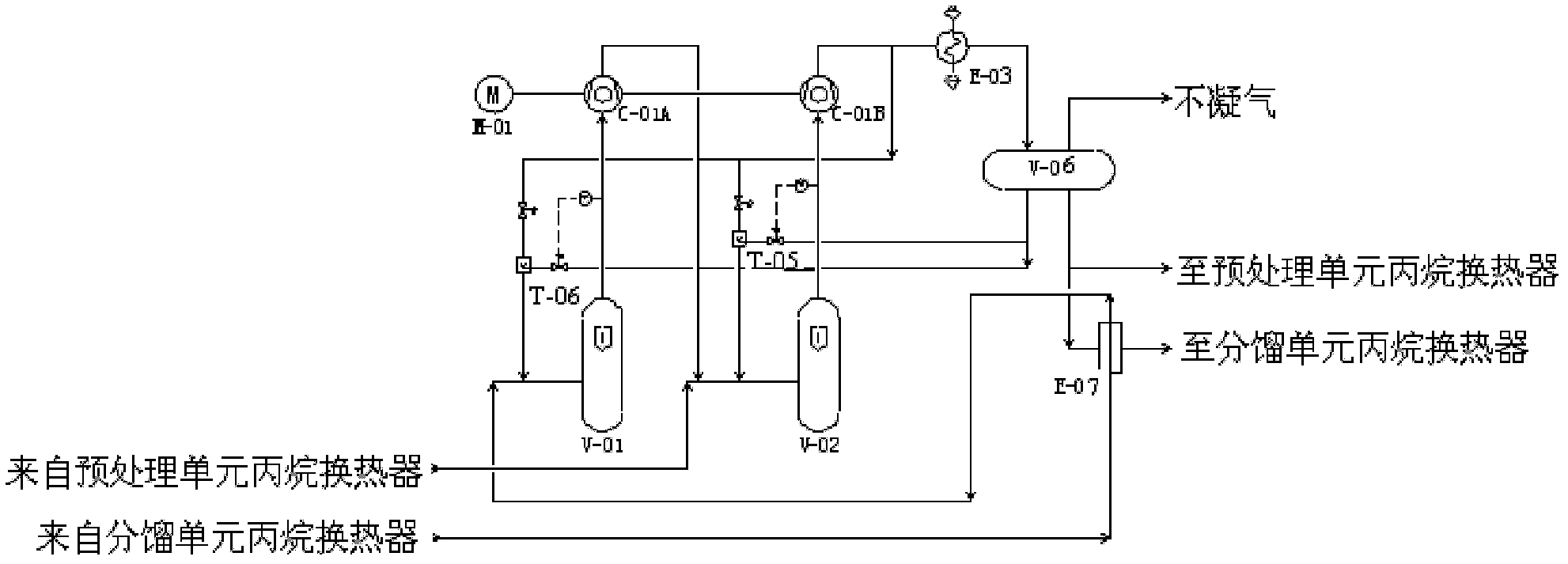

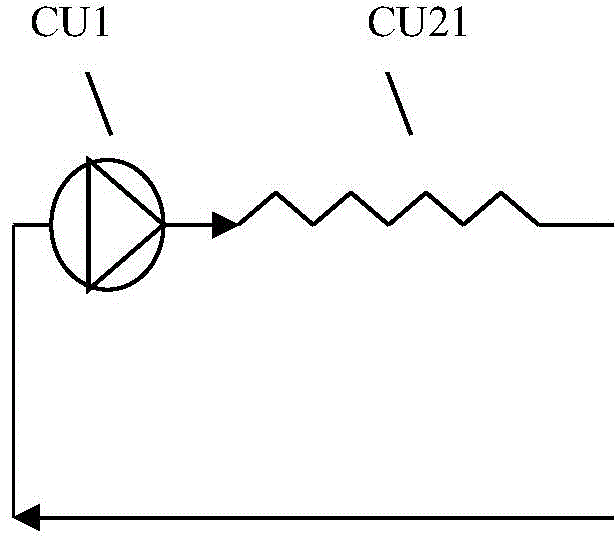

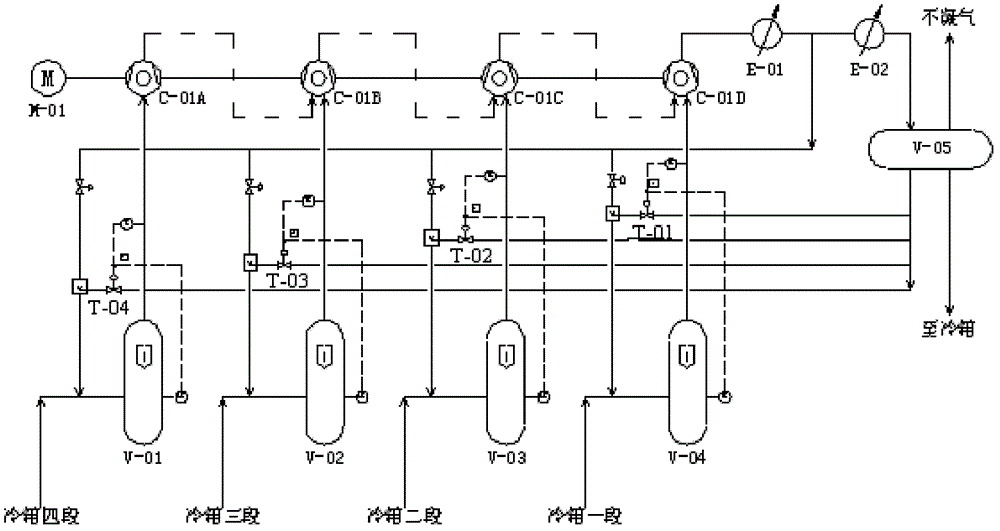

Method of reducing interstage temperature of propane compressor in propane compressor cycle refrigerating system

ActiveCN102562532AReduce heat transfer loadImprove work efficiencyPositive displacement pump componentsFluid circulation arrangementLow loadEngineering

The invention discloses a method of reducing the interstage temperature of a propane compressor in a propane compressor cycle refrigerating system, and the method comprises the flowing steps: communicating a propane accumulating tank in the propane compressor cycle refrigerating system with each anti-surge pipeline or return pipeline, and arranging throttle valves the communicated pipelines; and arranging adjusting valves on the pipelines through which the propane accumulating tank is communicated with the anti-surge pipelines or the return pipelines. The method of reducing the interstage temperature of the propane compressor in the propane compressor cycle refrigerating system can be used for effectively improving the working efficiency of the compressor, reducing the heat exchange load of a heat exchanger at the outlet of the compressor, and eliminating the influence of change of interstage temperature of the compressor on the frige heat exchanger in low-load running working conditions.

Owner:CHINA NAT OFFSHORE OIL CORP +1

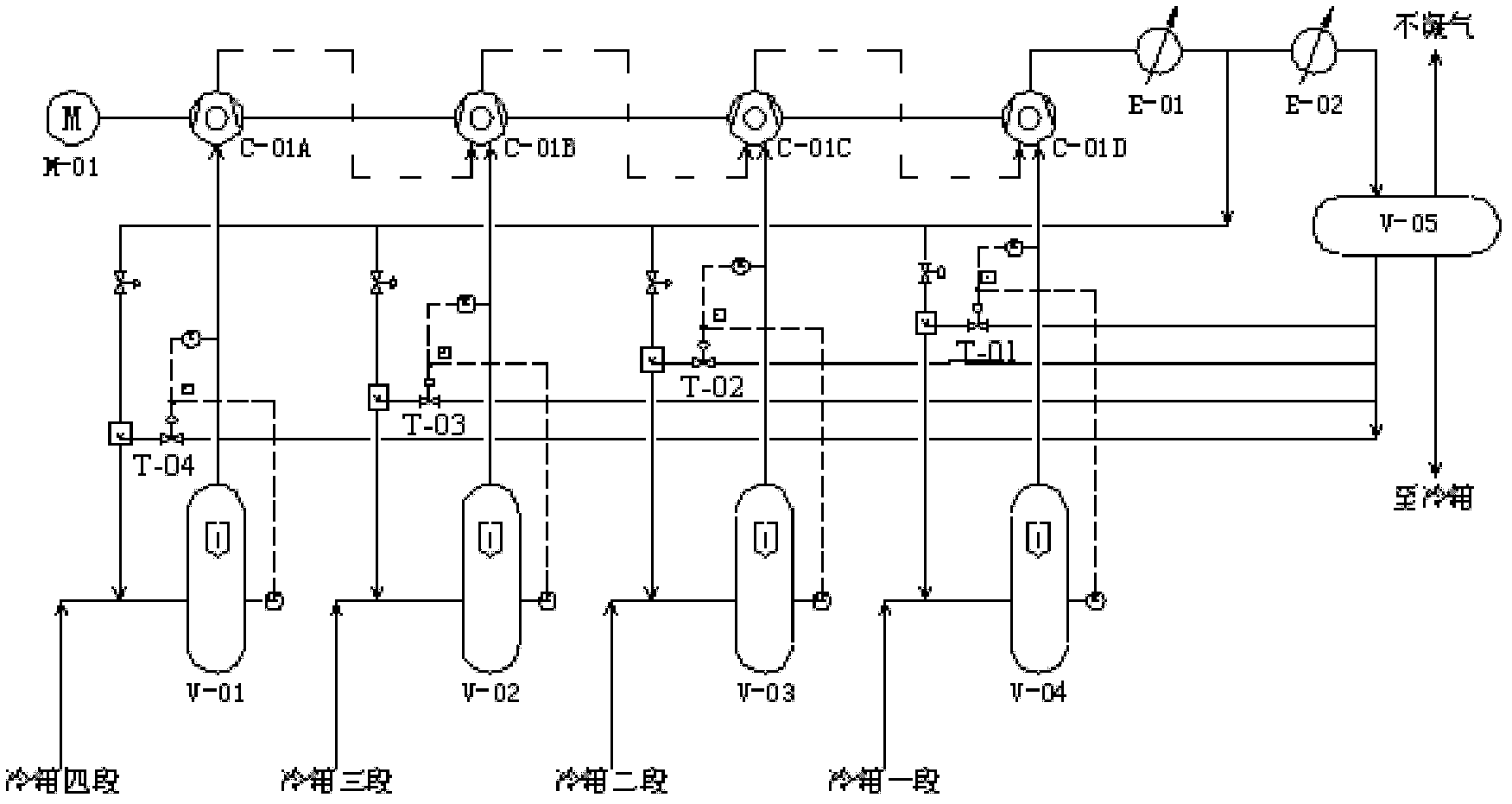

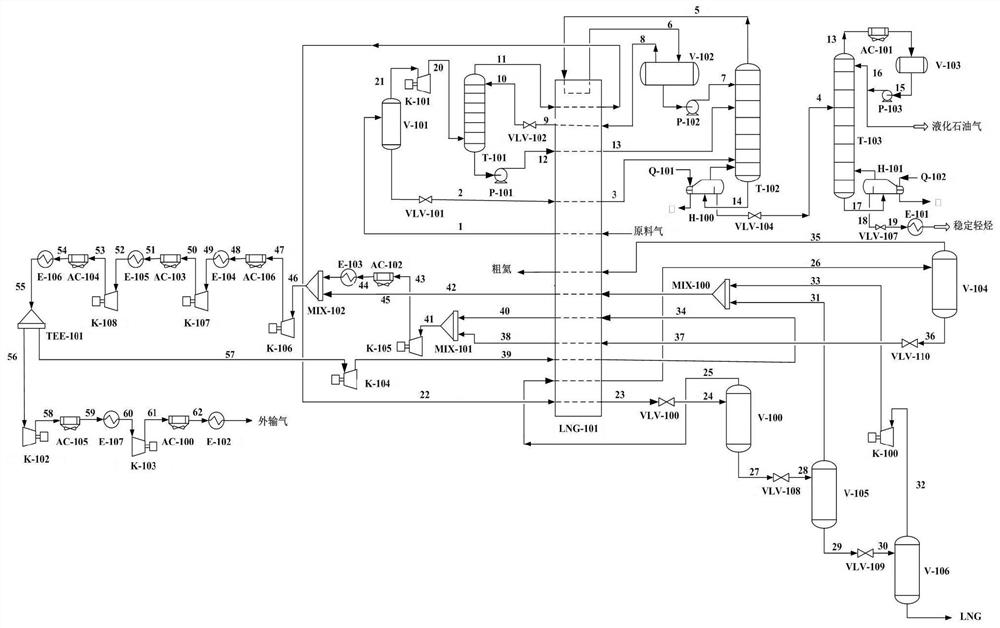

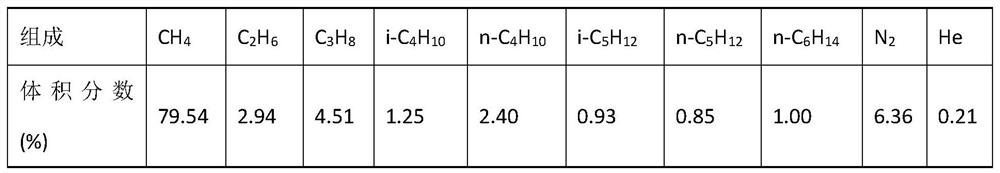

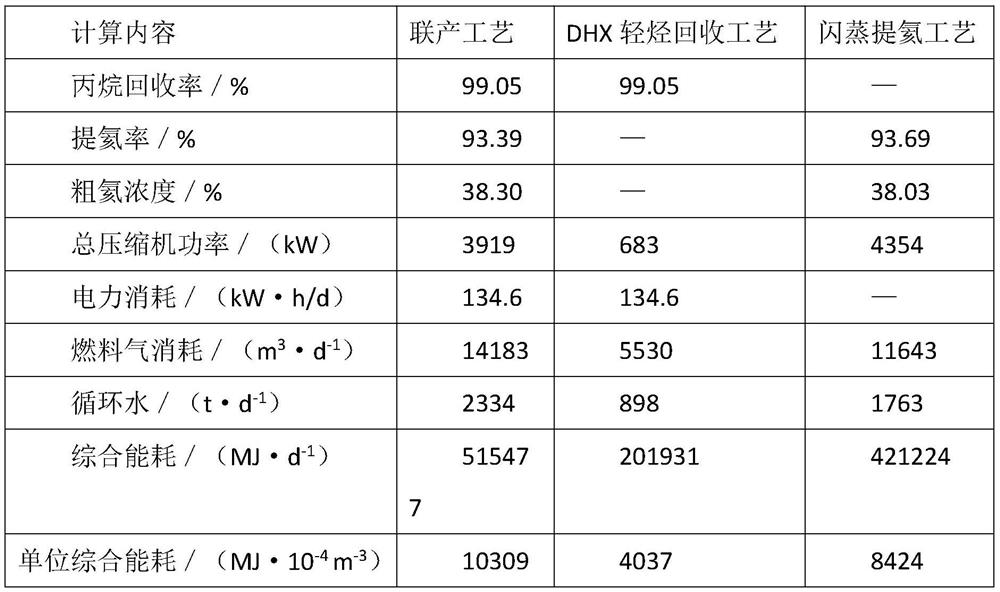

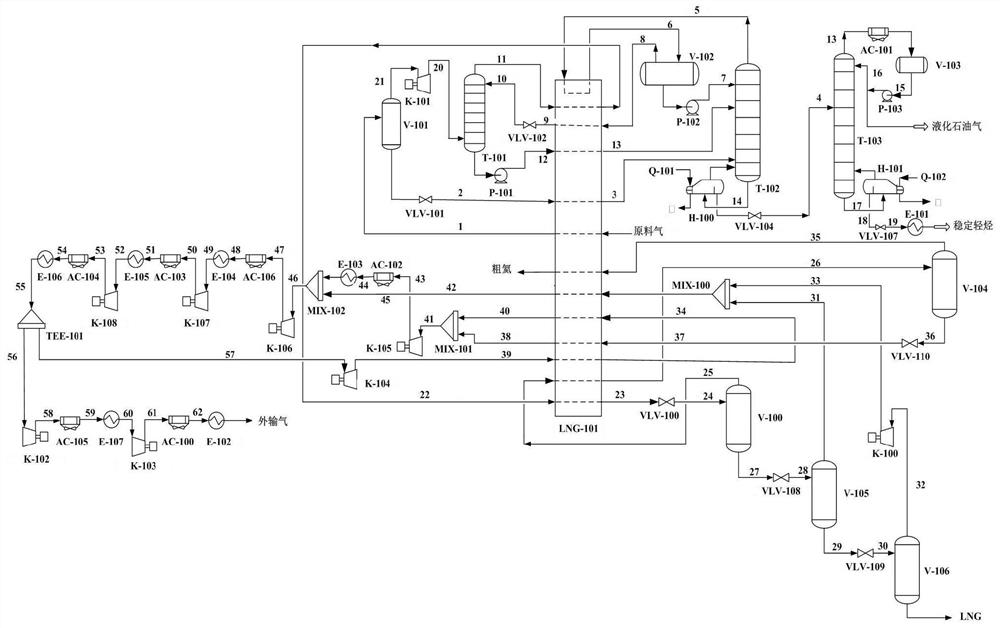

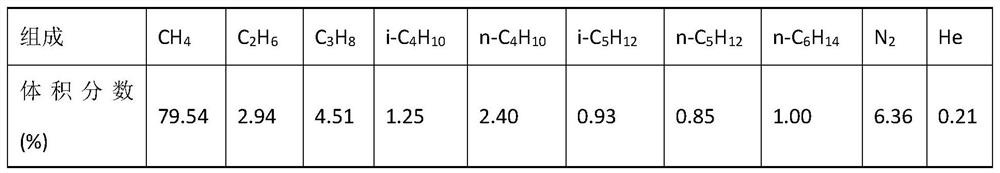

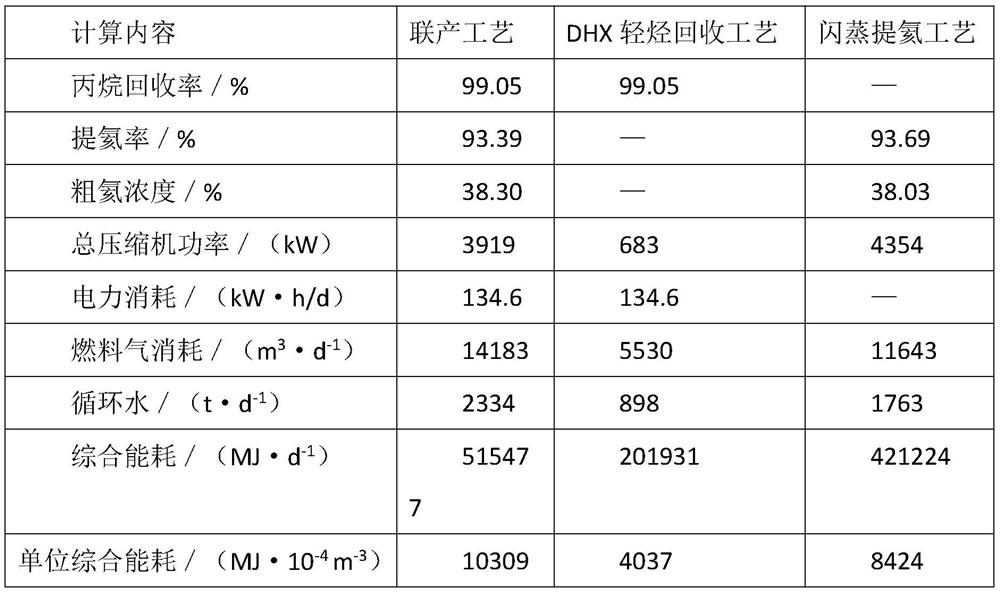

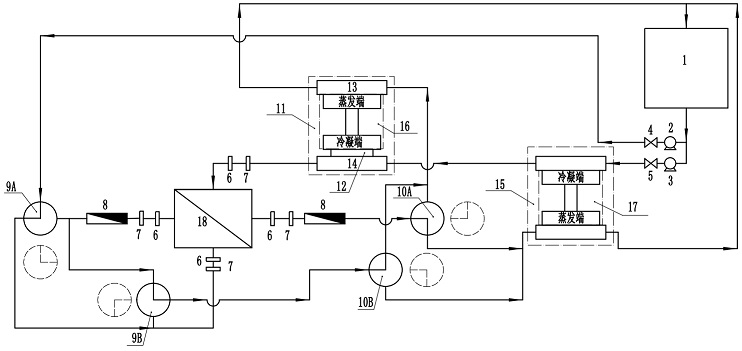

Recycling and helium-extracting co-production system and method for light hydrocarbons of helium-poor natural gas

ActiveCN112179048ALow costReduce energy consumptionSolidificationLiquefactionProcess engineeringEnvironmental geology

The invention discloses a recycling and helium-extracting co-production system and method for light hydrocarbons of helium-poor natural gas. The co-production system mainly comprises a heat exchanger,a low-temperature separator, a heavy contact tower, an ethane-removal device, a butane removal device, four flash tanks, three mixers, a plurality of compressors and a plurality of expanders. The co-production process utilizes an agent capable of automatically generating cold to refrigerate and expand a cold box to integrate heat exchange, and liquefied petroleum gas and stable light hydrocarbonsare obtained from raw material gas in the light hydrocarbon recycling device; dry gas of the light hydrocarbon recycling device enters a flash-evaporating helium-extracting device to gradually liquefy and separate to obtain LNG, externally conveyed gas and rough helium; and a low-temperature liquid-state natural gas product separated from the flash-evaporating helium-extracting device is taken asan agent capable of automatically generating cold through cascade cycle. Helium extracting and light hydrocarbon recycling are integrated, the heat exchanger is designed with high integrity, and theagent capable of automatically generating cold is adopted for cycle refrigeration; and compared with an existing process, the method overcomes the bottleneck of singe line production capacity, reducesliquefying cost and comprehensive energy consumption, improves performance, and has a practical application value.

Owner:KUNMING INST OF PRECIOUS METALS +1

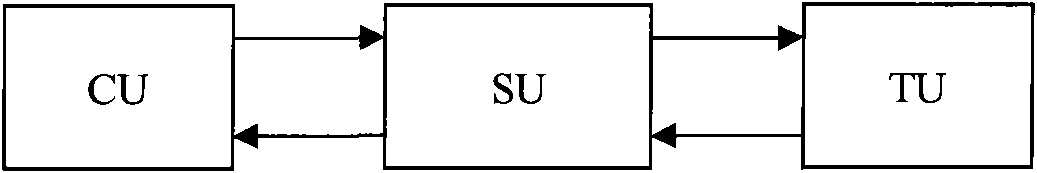

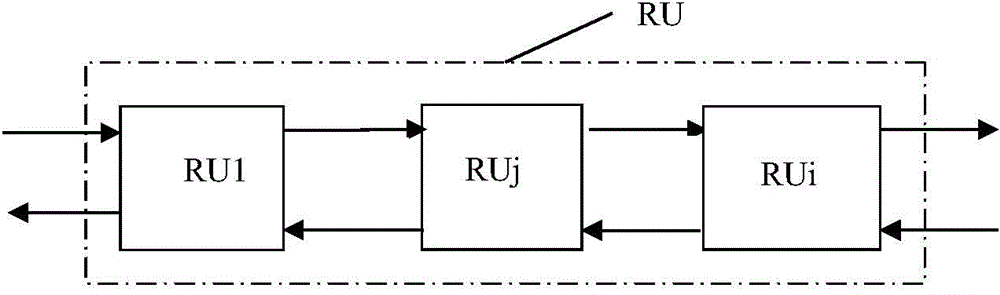

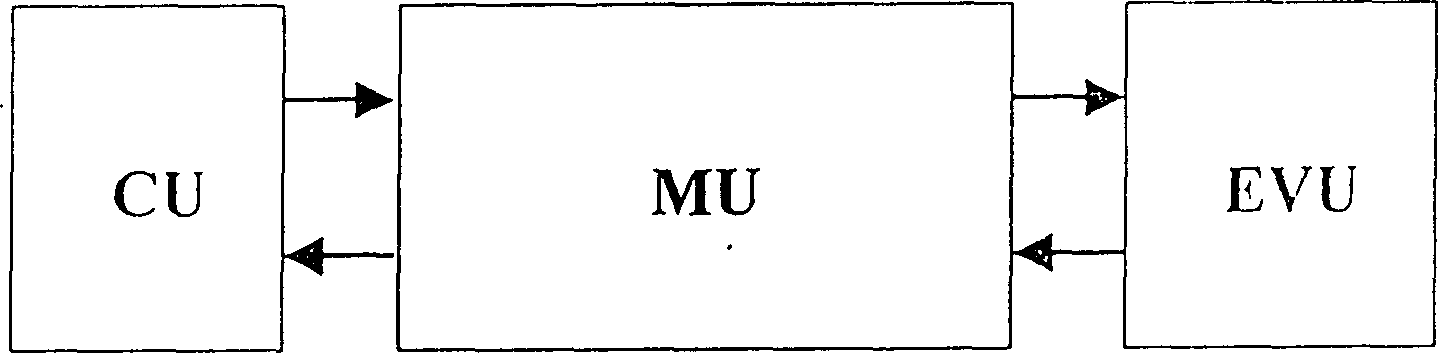

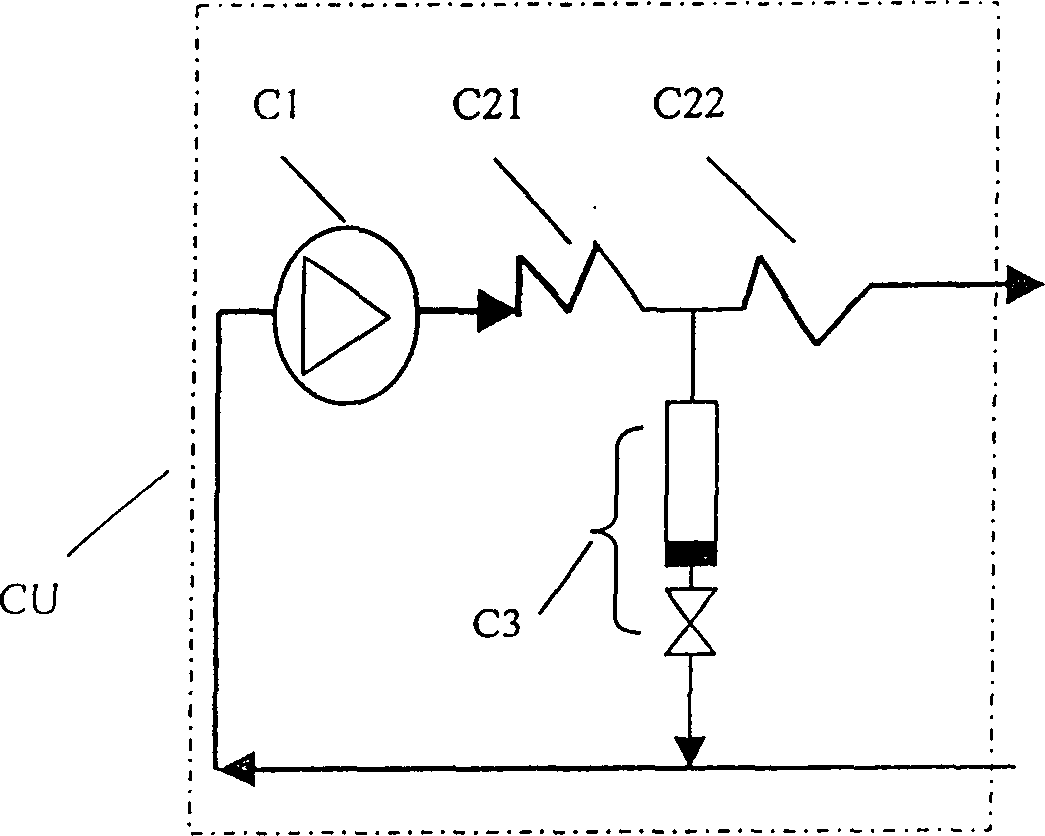

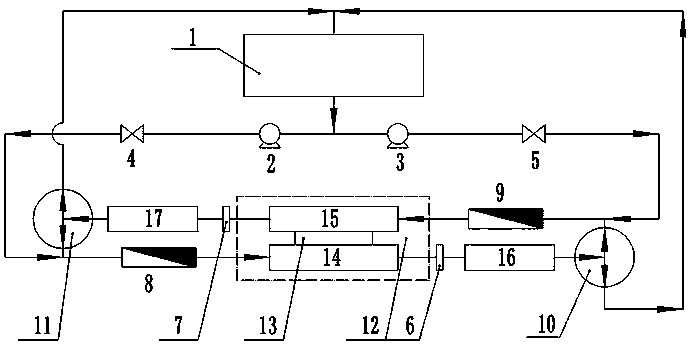

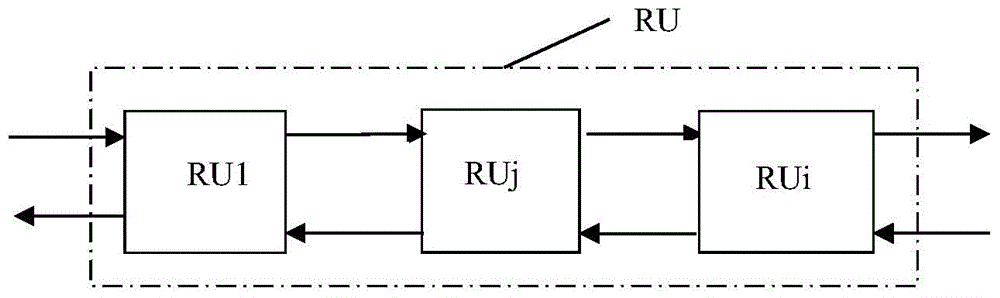

Low-temperature gas liquefaction and separation system applying effect of segregation

ActiveCN101625191ALiquefaction separation is effectiveImprove condensation separation driving forceSolidificationLiquefactionEnd stagesProduct gas

The invention relates to a low-temperature gas liquefaction and separation system applying the effect of segregation, which comprises a compressor module, a cooling and segregation module and a liquefaction and separation module, wherein a high-pressure outlet of the compressor module is connected with a refrigerant high-pressure inlet of the cooling and segregation module; a refrigerant high-pressure outlet of the cooling and segregation module is connected with a refrigerant high-pressure inlet of the liquefaction and separation module; a refrigerant low-pressure outlet of the liquefaction and separation module is connected with a refrigerant low-pressure inlet of the liquefaction and separation module, and a refrigerant low-pressure outlet of the cooling and segregation module is connected with a lower-pressure inlet of the compressor module; after pretreatment, mixed gas required to be separated enters the cooling and segregation module from a separated gas inlet and then enters the liquefaction and separation module; liquid separated out by each stage and tail gas output by an end stage enters respective preceding stages as required, and cold energy is recovered stage by stage or directly output. The system is driven by a single compressor so as to have reliable and simple operation, applies the segregation to realize separation in a heat exchanger and has simple structure and flexible arrangement.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

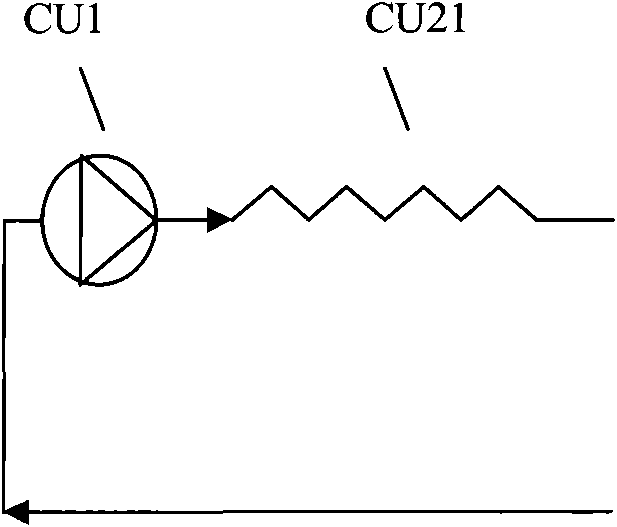

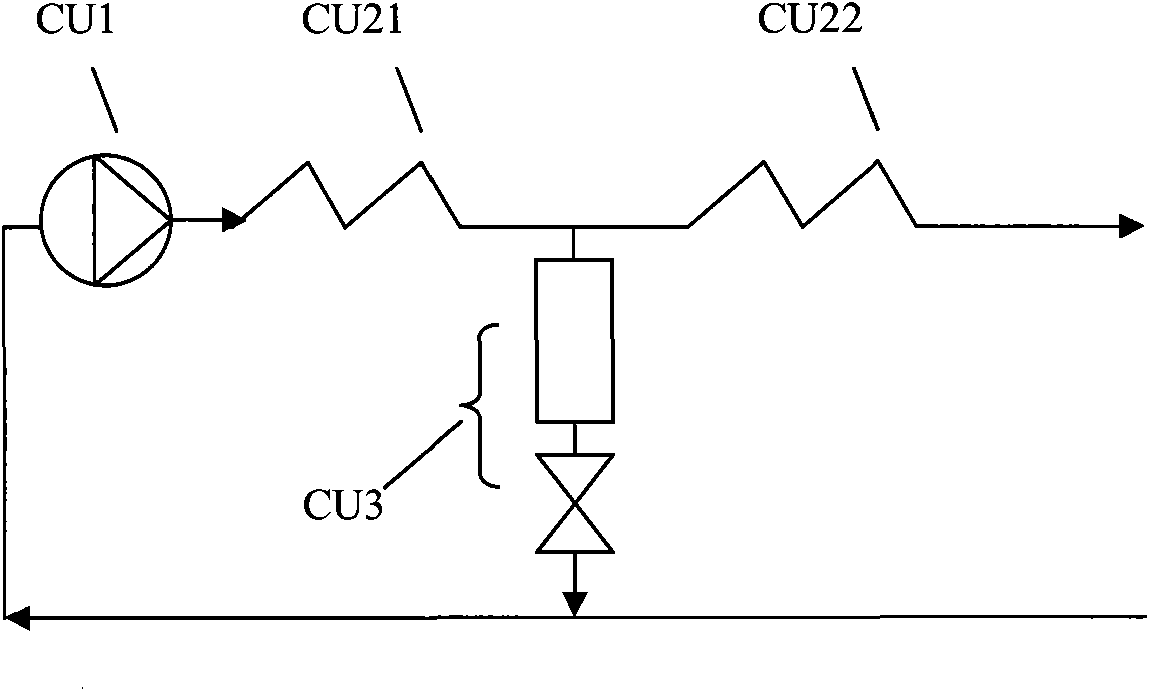

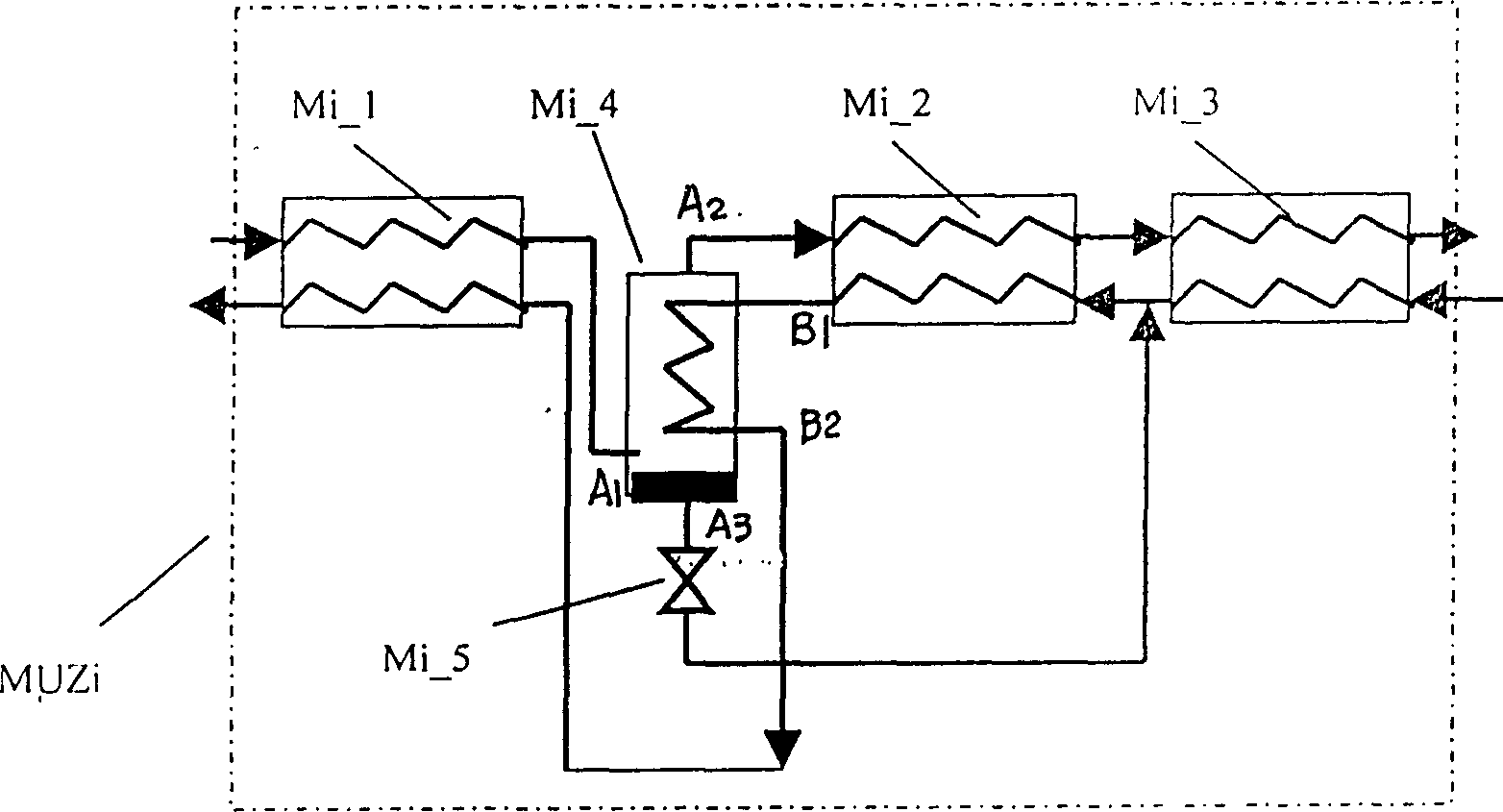

Multi-element mixed working medium back-heating type throttling and refrigerating circulation system with dephlegmator-separator

ActiveCN103822389AImprove efficiencyFlexible layoutCompression machines with non-reversible cycleSuperheatersRefrigeration compressorEngineering

A multi-element mixed working medium back-heating type throttling and refrigerating circulation system with dephlegmator-separator is composed of a compressor module, a back-heating heat exchanger module, a throttling module, an evaporative heat exchanging module and connecting pipes thereof. A high-pressure outlet of the refrigerating compressor module is connected with a refrigerant high-pressure inlet of the back-heating heat exchanger module, a refrigerant high-pressure outlet of the back-heating heat exchanger module is connected with a refrigerant high-pressure inlet of the throttling module, a refrigerant low-pressure inlet of the throttling module is connected with the evaporative heat exchanging module, an outlet of the evaporative heat exchanging module is connected with a refrigerant low-pressure inlet of the back-heating heat exchanger module, a refrigerant low-pressure outlet of the back-heating heat exchanger module is connected with a low-pressure inlet of the refrigerating compressor module. The back-heating heat exchanger module is composed of dephlegmator-separator sub modules from first stage to fifth stage, and the dephlegmator-separator sub module of any stage is of eight different structures. The system can realize refrigeration of fixed temperature zone at a low temperature effectively, and can also be applicable to fields with complicated load, such as multi-element gas liquefied separation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Carbon fiber production wastewater separation treatment and resource utilization process method and device

ActiveCN104891591BImprove biodegradabilityReduce processing costsOrganic chemistryOrganic compound preparationFiberCarbon fibers

The invention provides a separated treatment and resource utilization technological method and device for carbon fiber production wastewater. The device comprises a first vacuum pump unit, a second vacuum pump unit, an acrylonitrile removing tower, a dimethyl sulfoxide concentrating tower, a crude product tower and a refining tower. According to the method, wastewater containing 0.5%-1% of acrylonitrile and 1%-5% of dimethyl sulfoxide enters the acrylonitrile removing tower and is subjected to acrylonitrile removal through pressure reduction for separated treatment, tower bottom solution wastewater is subjected to water removal through pressure reduction in the dimethyl sulfoxide concentrating tower and the crude product tower, the content of dimethyl sulfoxide is up to 99%, the dimethyl sulfoxide is subjected to pressure-reducing distillation in the refining tower, and accordingly, dimethyl sulfoxide with the purity higher than 99.97% is obtained. According to the method and the device, the wastewater is subjected to acrylonitrile removal through pressure reduction for separated treatment, the environmental protection treatment problems that the wastewater containing acrylonitrile is difficult to degrade, the treatment cost is high and the like are solved, distillation extraction and high-purity refining recovery of low-concentration dimethyl sulfoxide in the wastewater are realized synchronously, the technological process is simple, the resource recovery efficiency is high, the purity of recovered dimethyl sulfoxide is high, and the wastewater treatment cost is greatly reduced.

Owner:HENAN YONGMEI CARBON FIBER +1

Multistage method for dehumidifying liquid

InactiveCN1185447CLower dew pointRegulate drynessLighting and heating apparatusDispersed particle separationLow densityAir conditioning

Owner:刘拴强

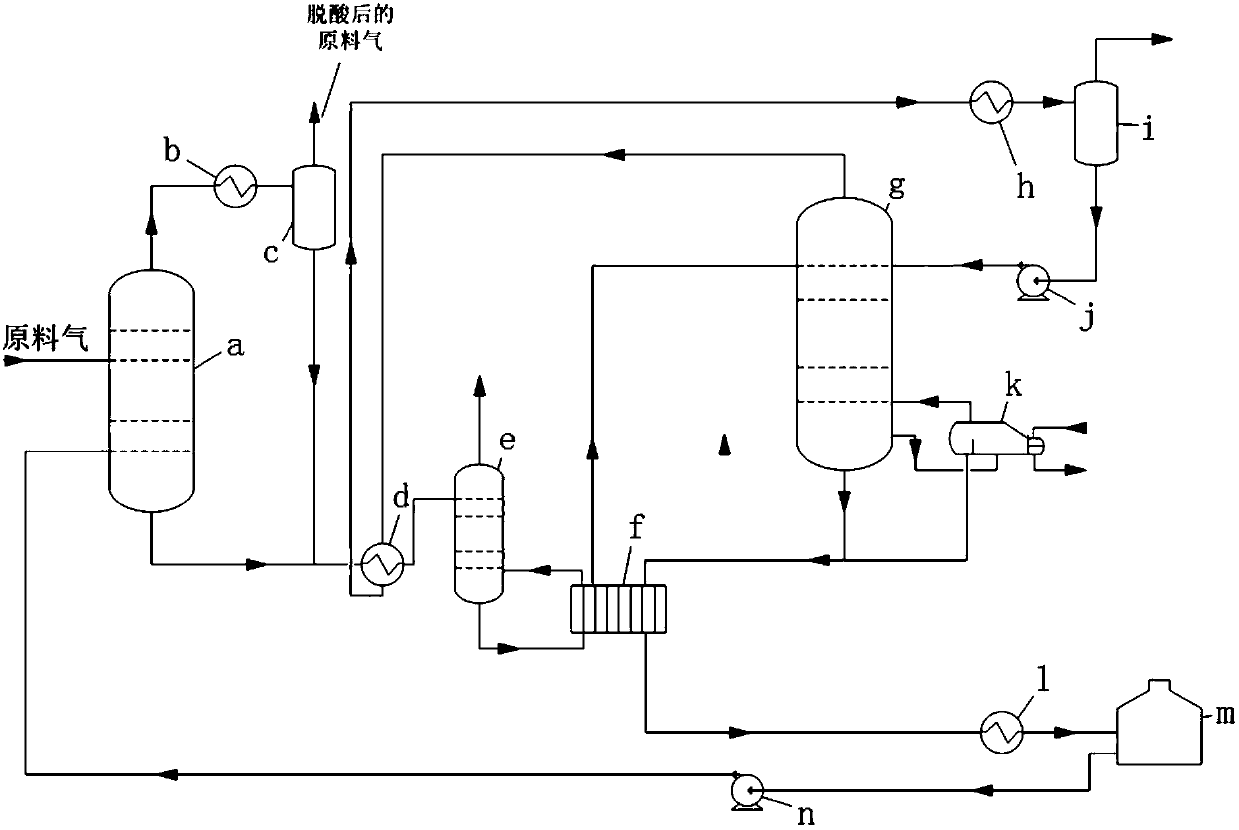

Amine solution regeneration system and amine solution regeneration process applied to floating liquefied natural gas facility

PendingCN108048147AIncrease temperatureAccelerated precipitationDispersed particle separationGaseous fuelsRefluxPlate heat exchanger

The invention relates to an amine solution regeneration system and an amine solution regeneration process applied to a floating liquefied natural gas facility. The system comprises an amine solution absorbing tower, wherein a top outlet of the amine solution absorbing tower is connected with a heat flow inlet of a treatment gas heat exchanger; a heat flow outlet of the treatment gas heat exchangeris connected with an inlet of a treatment gas buffer tank; a bottom liquid outlet of the treatment gas buffer tank is jointed with a bottom outlet of the amine solution absorbing tower and then is connected to a cold flow inlet of a waste heat use exchanger; a cold flow outlet of the waste heat use exchanger is connected with an inlet of an amine solution flash distillation column; a cold flow outlet of a poor / rich amine solution heat exchanger is connected with an inlet of an amine solution regeneration tower; a top outlet of the amine solution regeneration tower is connected with a heat flow inlet of the waste heat use exchanger; a heat flow outlet of the waste heat use exchanger is connected with a heat flow inlet of a regeneration tower top condenser; a heat flow outlet of the regeneration tower top condenser is connected with an inlet of a regeneration tower reflow tank; a bottom liquid outlet of the regeneration tower reflow tank is connected with an inlet of the amine solutionregeneration tower through a reflux pump.

Owner:CNOOC GAS & POWER GRP

Condensate water waste heat recycling and utilization device

InactiveCN106767050ATake advantage ofReduce manufacturing costHeat exchange apparatusStationary plate conduit assembliesWater dischargeEngineering

The invention relates to a condensate water waste heat recycling and utilization device which comprises a condensate water circulating unit, a technological returned-water circulating unit, a living returned-water circulating unit, a first heat exchanger and a second heat exchanger. The technological returned-water circulating unit communicates with a low-temperature-side water feeding pipe of the first heat exchanger and a low-temperature-side water discharging pipe of the first heat exchanger correspondingly, and the living returned-water circulating unit communicates with a low-temperature-side water feeding pipe of the second water exchanger and a low-temperature-side water discharging pipe of the second heat exchanger correspondingly; the condensate water circulating unit comprises a high-temperature condensate water box and a low-temperature condensate water box, and the high-temperature condensate water box communicates with the low-temperature condensate water box after passing through a high-temperature-side water feeding pipe of the first heat exchanger, a high-temperature-side water discharging pipe of the first heat exchanger, a high-temperature-side water feeding pipe of the second water exchanger and a high-temperature-side water discharging pipe of the second heat exchanger. Compared with the prior art, cooling of condensate water and heating of technological circulated-water returned-water and living circulated-water returned-water are integrated, the heat utilization rate is high, energy is saved, and consumption is lowered.

Owner:NINGBO CITY HANGZHOUWAN NEW DISTRICT XIANGYUAN POWER SUPPLYING

An ethane recovery method suitable for rich gas with absorption tower

ActiveCN108731380BHigh recovery rateGood absorption cooling effectSolidificationLiquefactionFractionationCooling effect

Owner:SOUTHWEST PETROLEUM UNIV

Multi-element mixed work medium condensating, separating, throttling and oleep cooling circular refrigeration system

InactiveCN1122797CAvoid cloggingChange the water equivalent ratioCompression machines with cascade operationPolyolEngineering

The multi-component mixed working medium segregation, separation, throttling and throttling cryogenic refrigeration cycle system involved in the present invention includes a compressor, an intermediate refrigeration and an evaporator module; the compressor module is composed of a compressor, a front cooler and a filter oil return device; the intermediate refrigeration module It consists of multi-stage mixed working medium refrigeration sub-modules, each sub-module includes a decondensation separator, a throttling element and a counterflow heat exchanger; the evaporator module includes a throttling element, an evaporator and a counterflow heat exchanger; the refrigerator adopts a high-efficiency Multi-component non-azeotropic mixed working fluid, no environmental hazards, driven by a single compressor, simple and reliable, multi-component mixed working fluid internal cascade refrigeration, reliable performance of the refrigerator, high refrigeration efficiency.

Owner:中科赛凌(北京)科技有限公司

Cascade refrigerating circulating system coupled with injector

ActiveCN105650922AImprove heat transfer coefficientReduce power consumptionMechanical apparatusCompression machines with cascade operationVapor–liquid separatorProcess engineering

The invention discloses a cascade refrigerating circulating system coupled with an injector. Overheat steam exhausted by a high-temperature-level compressor and a low-temperature-level compressor in the system will heat and gasify a high-temperature-level overcooled liquid refrigerant which is boosted through a booster pump to be under generation pressure, and generated saturated steam is used as working steam of refrigerant flash evaporation gas which is separated through a gas-liquid separator after injecting of an injector and high-temperature-level throttling are conducted. Due to the fact that sensible heat of overheat gas exhausted by the low-temperature-level compressor is utilized in a three-channel generator, loads of a condensation evaporator are effectively reduced, in other words, the refrigerating amount of high-temperature-level refrigerating circulation is reduced, on the premise of the high-temperature-level and low-temperature-level working conditions and the same low-temperature-level refrigerating amount, refrigerating loads of high-temperature-level circulation and power consumption of the compressors will be reduced, and the COP of the whole cascade refrigerating circulation will be improved. It can be obtained that the refrigerating coefficient of the cascade refrigerating circulating system will be increased by 10% or so compared with the refrigerating coefficient of a traditional cascade refrigerating system through preliminary estimation on the cascade refrigerating system composed of NH3 and CO2.

Owner:SOUTHEAST UNIV

A desktop self-supply water heat exchanger performance testing device

InactiveCN110823616BFulfil requirementsAccuracy meetsStructural/machines measurementExpansion tankEnergy recovery

The present invention provides a desktop type self-supply water heat exchanger performance test experiment device based on semiconductor heat pump, which utilizes semiconductor heat pump technology, has small volume, flexible control, and adapts to the requirements of desktop systems; realizes energy saving, especially when hot and cold water are supplied at the same time. Compensation, recovery of energy from cold and heat sources; circulating water supply, no need for upper and lower water, convenient and flexible experiments, not limited by the position of upper and lower water pipes; heat exchanger type expansion tank is adopted, bulky cold and hot water tanks are discarded, and the structure is compact, realizing hot and cold water The mixed cold and heat compensation heat exchange reduces the heat exchange load of the environment, and at the same time realizes water replenishment, constant pressure, and removal of system gas or excess water; the flow rate is independently adjusted and is not affected by other factors, and each test condition is easy to achieve; considering downstream and countercurrent test conditions and its influence on energy recovery thermodynamic efficiency to maximize energy recovery; the invention is flexible and convenient, compact in structure, water-saving, environmentally friendly, and energy-saving, and can realize the thermal performance and thermal performance of liquid-liquid heat exchangers The resistance characteristic test is widely applicable to the experimental teaching and testing needs of heat exchangers.

Owner:QINGDAO UNIV

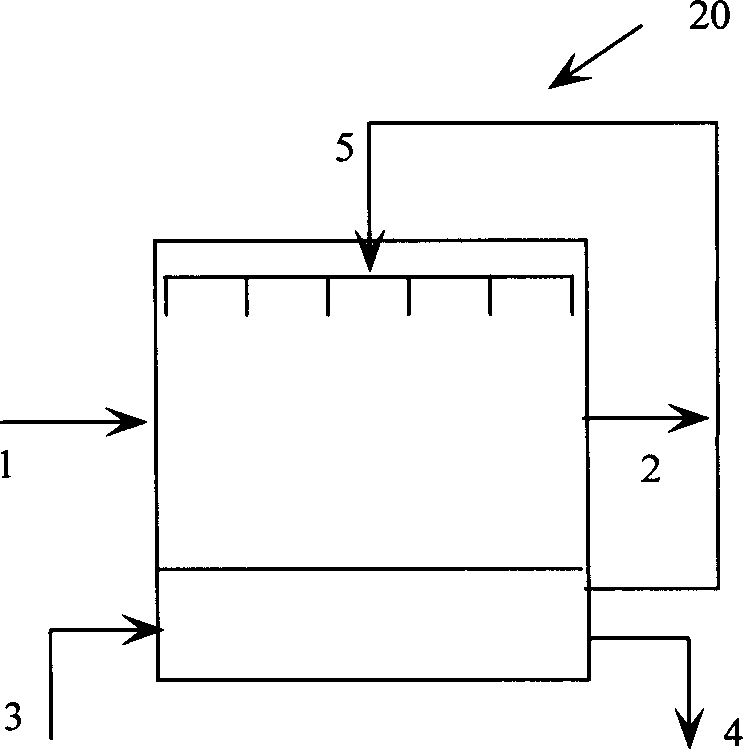

Wide-temperature-area multi-mode water supply device

InactiveCN109737488ARealize mixed cold and heat compensation heat exchangeAvoid wastingLighting and heating apparatusSpace heating and ventilation detailsWater useWater saving

The invention provides a multi-mode circulating water supply device. The device comprises an expansion heat exchanger, a first water pump, a second water pump, a first adjusting valve, a second adjusting valve, a first temperature sensor, a second temperature sensor, a first flow sensor, a second flow sensor, a first proportional distribution valve, a second proportional distribution valve and a heat pump; and the device uses a heat pump technology for realizing the energy compensation, saves water to achieve recycling to prevent wastes of water resources, adopts the expansion heat exchanger to reduce environmental heat exchange loads, and synchronously realizes water supply, pressure fixation and exhausting of system gas or excessive water. The device is flexible, convenient, compact in structure, water-saved, environment-friendly and energy-saved, can realize constant-temperature and constant-flow water supply in different temperature areas under different heat loads, and is widely suitable for the water supply demands of different laboratories with different temperature areas and loads and other water use places.

Owner:QINGDAO UNIV

Iterative cooling system refrigerated via mixed work medium for throttling and low temperature eddy expansion

InactiveCN1140738CImprove reliabilityReduce vibrationCompression machines with cascade operationVapor–liquid separatorEngineering

The circular refrigerating system includes compressor assembly, intermediate assembly and vortex tube refrigeration assembly; the compressor assembly consists of compressor, front cooler and filtering oil feeder; the intermediate throttling refrigeration assembly consists of 2-3 stage mixed work medium throttling refrigeration sub-modules including gas-liquid separator, throttling element and countercurrent heat exchanger; and the vortex tube refrigeration assembly includes vortex tube, evaporator and countercurrent heat exchanger. In the refrigerator, single compressor for simple and reliable driving and high efficiency multi-component mixed work medium are used without environment harm.

Owner:LOW TEMPERATURE TEST CENT CHINESE ACAD OF SCI

A wide temperature zone multi-mode water supply device

InactiveCN109737488BRealize mixed cold and heat compensation heat exchangeAvoid wastingLighting and heating apparatusSpace heating and ventilation detailsWater useProcess engineering

The invention provides a multi-mode circulating water supply device. The device comprises an expansion heat exchanger, a first water pump, a second water pump, a first adjusting valve, a second adjusting valve, a first temperature sensor, a second temperature sensor, a first flow sensor, a second flow sensor, a first proportional distribution valve, a second proportional distribution valve and a heat pump; and the device uses a heat pump technology for realizing the energy compensation, saves water to achieve recycling to prevent wastes of water resources, adopts the expansion heat exchanger to reduce environmental heat exchange loads, and synchronously realizes water supply, pressure fixation and exhausting of system gas or excessive water. The device is flexible, convenient, compact in structure, water-saved, environment-friendly and energy-saved, can realize constant-temperature and constant-flow water supply in different temperature areas under different heat loads, and is widely suitable for the water supply demands of different laboratories with different temperature areas and loads and other water use places.

Owner:QINGDAO UNIV

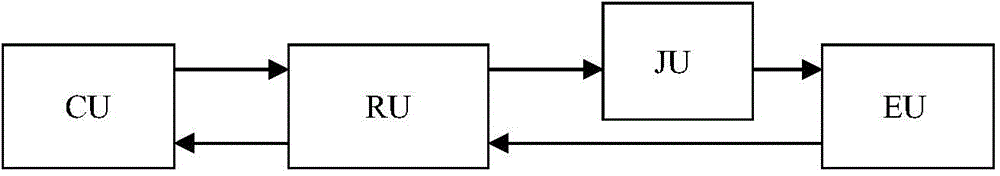

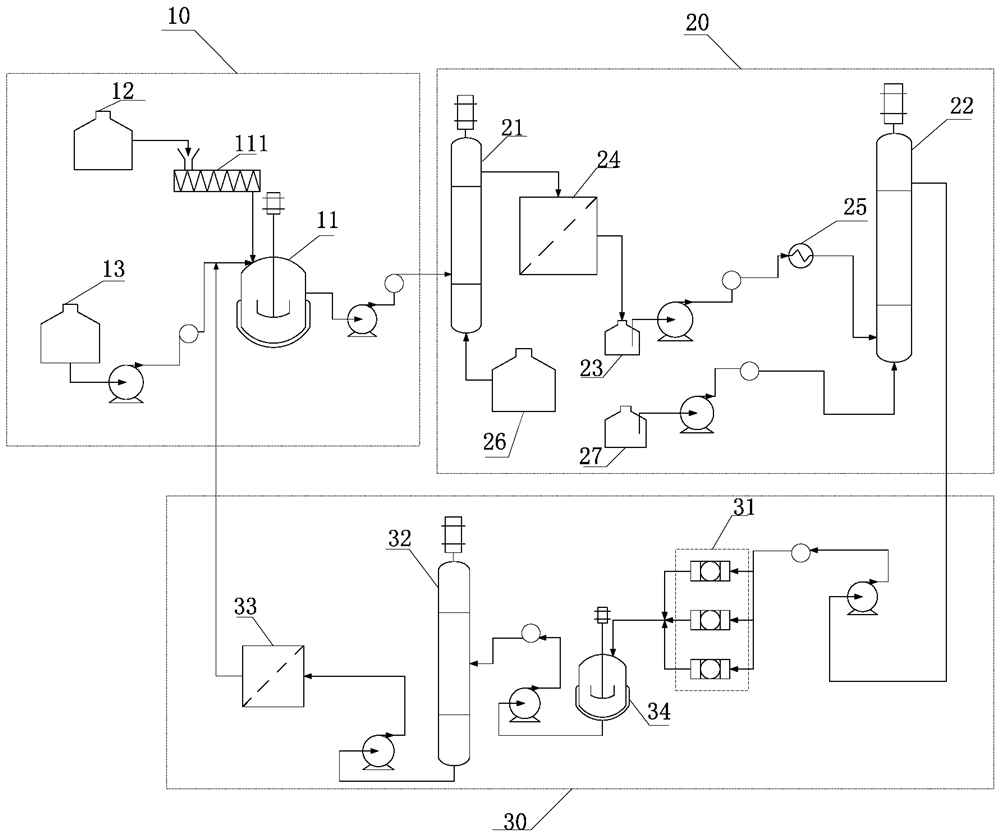

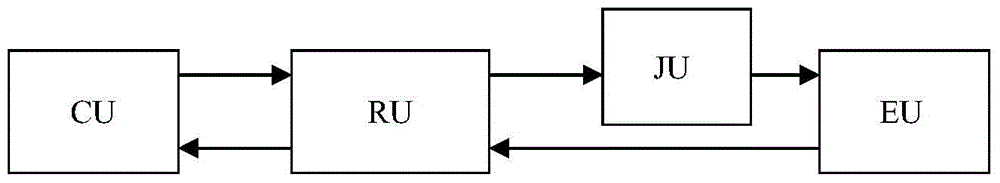

Continuous synthesis system and method of dicyandiamide

InactiveCN114105827ARealize continuous productionPrecise and Efficient ControlOrganic chemistryOrganic compound preparationProcess engineeringIndustrial engineering

The invention provides a continuous synthesis system and method of dicyandiamide. According to the material flowing sequence, the continuous synthesis system comprises a raw material pretreatment unit and a synthesis unit which are sequentially communicated through a conveying pipeline, and the raw material pretreatment unit comprises a raw material pretreatment device. Based on the system, the continuous production of dicyandiamide by taking lime nitrogen as a raw material is effectively realized, the filtering frequency is reduced, and the product loss is reduced. Meanwhile, based on the arrangement of the system, the reaction conditions can be more accurately and efficiently controlled, so that the reaction yield and the production efficiency of dicyandiamide are further improved.

Owner:TIANJIN ASYMCHEM MEDICAL SCI & TECH DEV CO LTD

A co-production system and method for recovering light hydrocarbons from helium-depleted natural gas and extracting helium

ActiveCN112179048BPrevent plug flowReduce lossesSolidificationLiquefactionRefrigerationLiquefied petroleum gas

The invention discloses a cogeneration system and method for recovering light hydrocarbons from helium-depleted natural gas and extracting helium. The cogeneration system mainly includes a heat exchanger, a low-temperature separator, a heavy contact tower, a deethanizer, a debutanizer, Four flash tanks, three mixers, multiple compressors, and multiple expanders; the cogeneration process uses self-produced refrigerant refrigeration plus expansion refrigeration plus cold box integrated heat exchange, and the raw gas is liquefied in the light hydrocarbon recovery unit Petroleum gas and stable light hydrocarbons; the dry gas from the light hydrocarbon recovery unit enters the flash helium extraction unit, and is gradually liquefied and separated to obtain LNG, externally transported gas and crude helium, and the low-temperature liquid natural gas products separated from the flash helium extraction unit are cascaded cycle as self-generating refrigerant. The invention integrates helium extraction and light hydrocarbon recovery, has a highly integrated design for the heat exchanger, and adopts self-produced refrigerant cycle refrigeration. Compared with the existing technology, it overcomes the bottleneck of single-line production capacity, reduces liquefaction costs and comprehensive Energy consumption is reduced, the performance of the device is improved, and it has practical application value.

Owner:KUNMING INST OF PRECIOUS METALS +1

A desktop self-water supply heat exchanger performance testing device

InactiveCN110806328BAccuracy meetsRealize mixed cold and heat compensation heat exchangeStructural/machines measurementExpansion tankEnergy recovery

The present invention provides a desktop type self-supply water heat exchanger performance test experiment device based on semiconductor heat pump, which utilizes semiconductor heat pump technology, has small volume, flexible control, and adapts to the requirements of desktop systems; realizes energy saving, especially when hot and cold water are supplied at the same time. Compensation, recovery of energy from cold and heat sources; circulating water supply, no need for upper and lower water, convenient and flexible experiments, not limited by the position of upper and lower water pipes; heat exchanger type expansion tank is adopted, bulky cold and hot water tanks are discarded, and the structure is compact, realizing hot and cold water The mixed cold and heat compensation heat exchange reduces the heat exchange load of the environment, and at the same time realizes water replenishment, constant pressure, and removal of system gas or excess water; the flow rate is independently adjusted and is not affected by other factors, and each test condition is easy to achieve; considering downstream and countercurrent test conditions and its influence on the thermodynamic efficiency of energy recovery to maximize energy recovery; use heat pipes for heat transport, flexible pipeline layout, long-distance transport, and negligible heat loss; the invention is flexible, convenient, and structurally Compact, water-saving, environmentally friendly, and energy-saving, it can realize the thermal performance and resistance characteristics testing of liquid-liquid heat exchangers, and is widely applicable to the experimental teaching and testing needs of heat exchangers.

Owner:QINGDAO UNIV

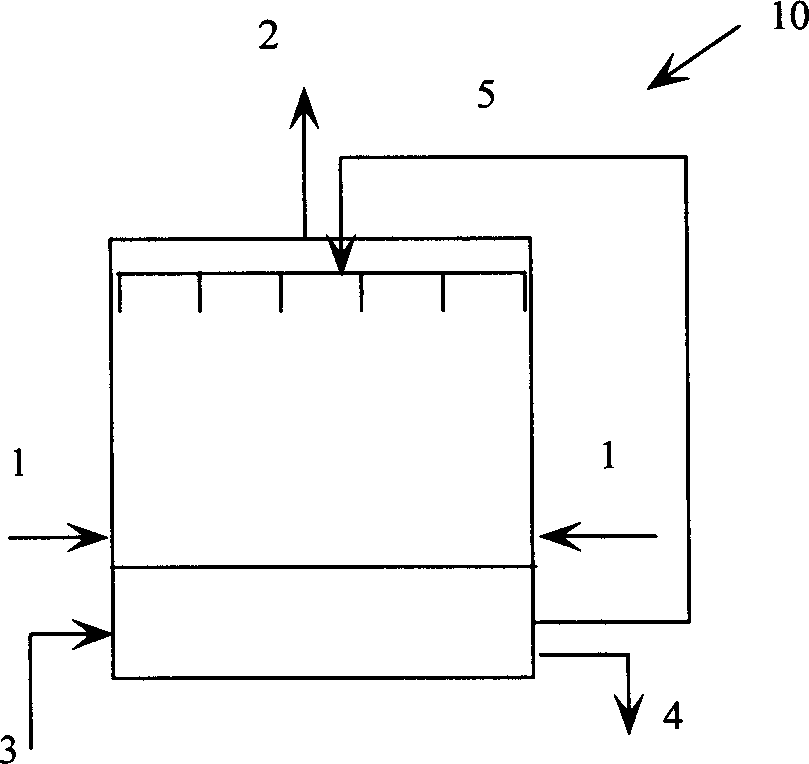

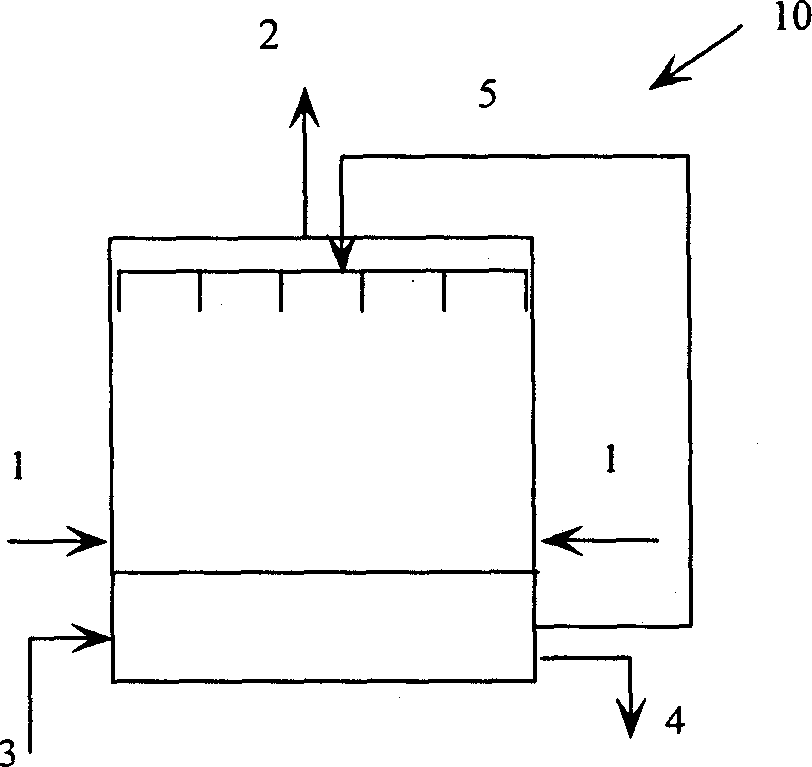

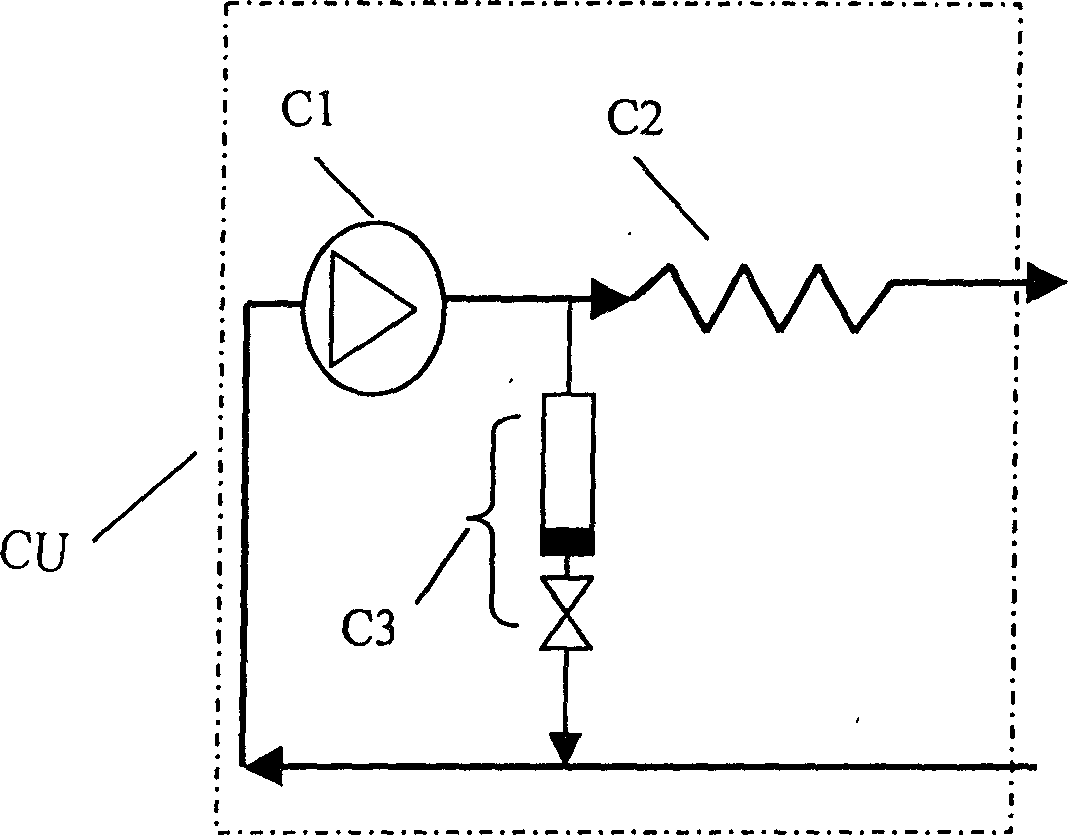

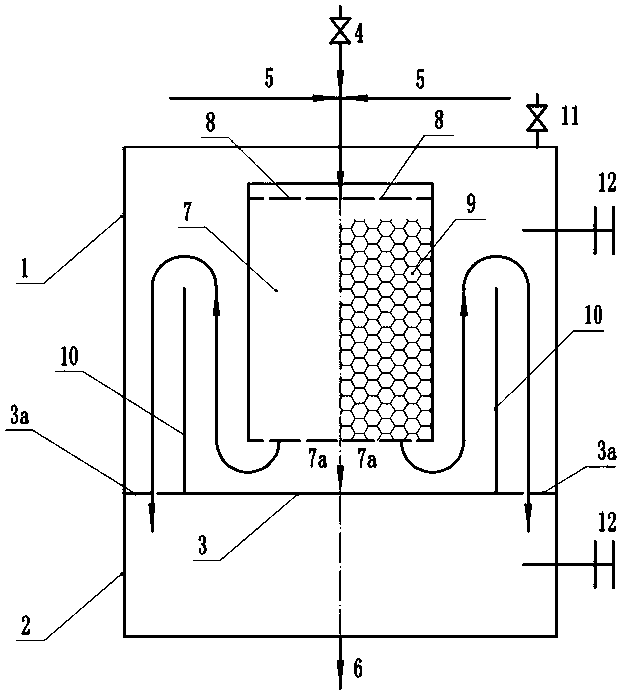

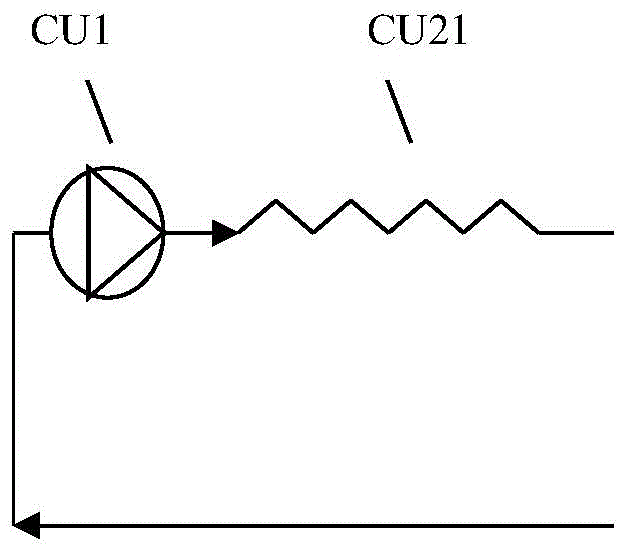

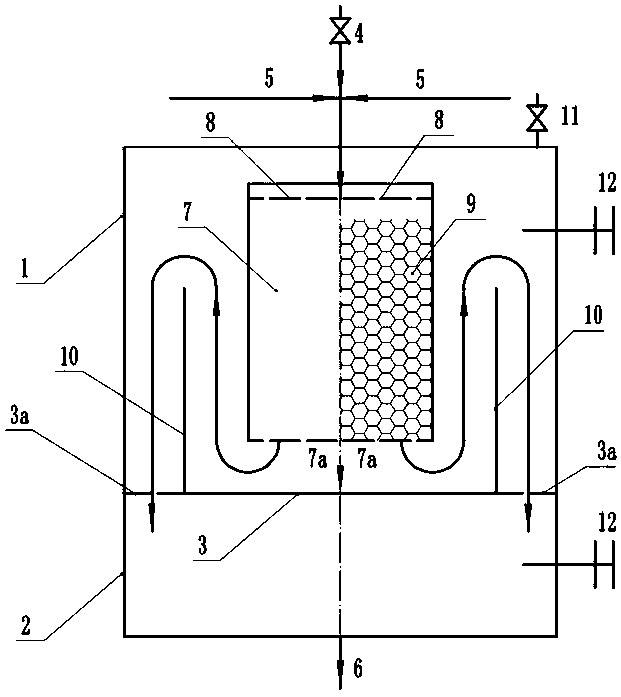

An expansion heat exchanger

InactiveCN109737770BReduce heat transfer loadRealize mixed cold and heat compensation heat exchangeHeat exchanger casingsDirect contact heat exchangersExpansion tankWater saving

The invention provides an expansion type heat exchanger based on mixed heat exchange. The expansion type heat exchanger comprises an expansion section, a water supply section, a partition, a water supplement port, an inlet, an outlet, a direct mixing heat exchanger, a water distribution mechanism, a filler, an annular weir plate, an automatic exhaust valve and a liquid level sensor. The heat exchanger and an expansion water tank are organically combined, the structure is reasonable and compact, the utilization rate of equipment is increased, the manufacturing cost is lowered, and the occupiedspace is reduced. By the adoption of the expansion type heat exchanger, the mixed cold and hot compensation heat exchange of cold and hot water is realized, the environmental heat exchange load is reduced, and meanwhile water supplement, constant pressure and elimination of system gas or over-filled water are realized. The expansion type heat exchanger is flexible and convenient to use, compact instructure and environmentally-friendly, saves water, saves energy and is widely applicable to cold and hot water supply occasions with different temperature regions and different heat loads.

Owner:QINGDAO UNIV

A cascaded refrigeration cycle system coupled with an ejector

ActiveCN105650922BAvoid power consumptionReduce power consumptionMechanical apparatusCompression machines with cascade operationVapor–liquid separatorFlash-gas

The invention discloses a cascaded refrigeration cycle system coupled with an ejector. In the system, the superheated steam discharged from the high and low temperature stage compressor will be heated and vaporized and then boosted by a booster pump to the high temperature stage supercooled liquid refrigeration under the generation pressure. The saturated steam generated is used as the working steam of the refrigerant flash gas separated by the gas-liquid separator after the ejector injects the high-temperature stage throttling. Since the sensible heat of the superheated gas discharged from the low-temperature stage compressor is utilized in the three-channel generator, the load of the condensing evaporator is effectively reduced, that is, the cooling capacity of the high-temperature stage refrigeration cycle is reduced. Under the premise of the same cooling capacity of the low-temperature stage, the refrigeration load of the high-temperature stage cycle and the power consumption of the compressor will be reduced, and the COP of the entire cascade refrigeration cycle will be improved. A preliminary estimate of the cascade refrigeration system composed of NH3 and CO2 can be obtained: the refrigeration coefficient of this system will be increased by about 10% compared with the traditional cascade refrigeration system.

Owner:SOUTHEAST UNIV

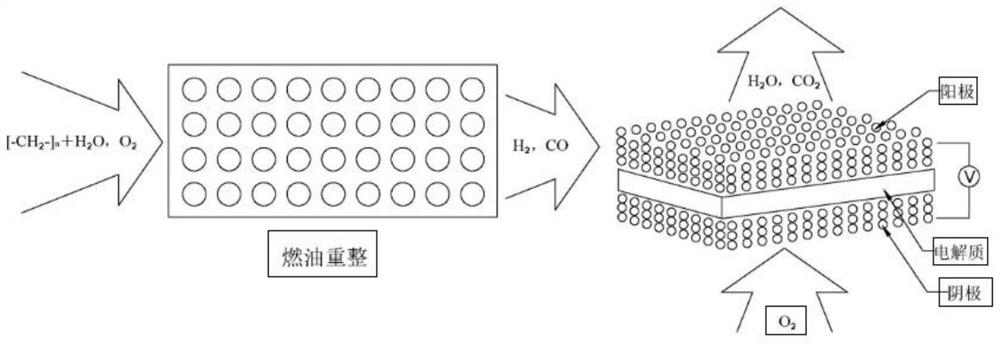

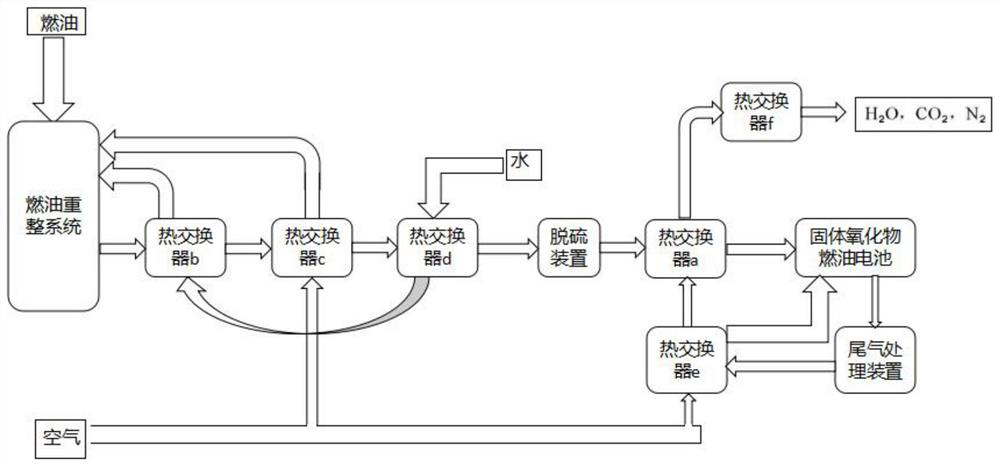

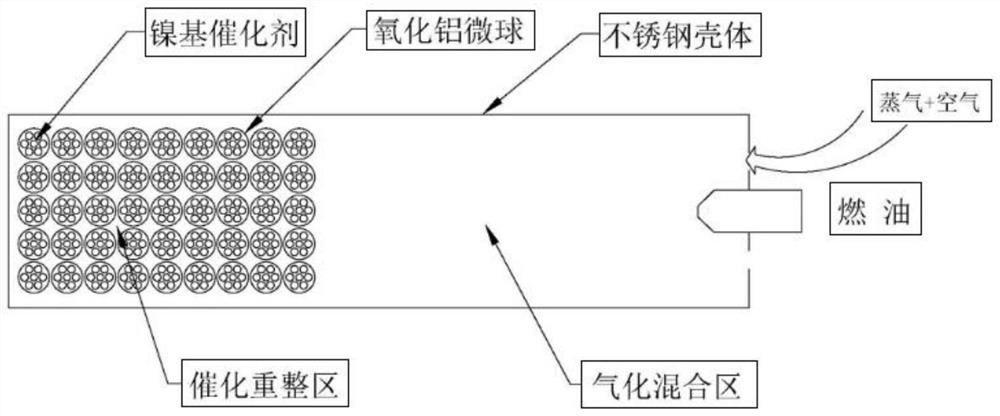

A high-efficiency silent power generation device based on fuel catalytic reforming

ActiveCN110165260BReduce volumeImprove power densityFuel cellsCatalytic reformingElectrical conductor

The invention discloses an efficient silent power generation device based on fuel catalytic reforming, and relates to the technical field of power equipment. The efficient silent power generation device comprises a fuel reforming system, a solid oxide fuel cell and an integrated control system, wherein the fuel reforming system comprises a micro-channel reactor and an alumina microsphere disposedin the micro-channel reactor, and is used for gasifying and reforming the fuel oil into a fuel gas; the solid oxide fuel cell includes an oxygen ion conductor electrolyte plate, a fuel electrode and an air electrode; the integrated control system includes an electronic control system and a thermal management system. The efficient silent power generation device converts the fuel oil into CO, H2 andCH4 through the fuel reforming system so as to provide fuel for the fuel cell, solves the hydrogen and methane storage and transportation problem of the traditional fuel cell, and achieve the power generation energy efficiency of 40%.

Owner:北京中科三鼎科技有限公司

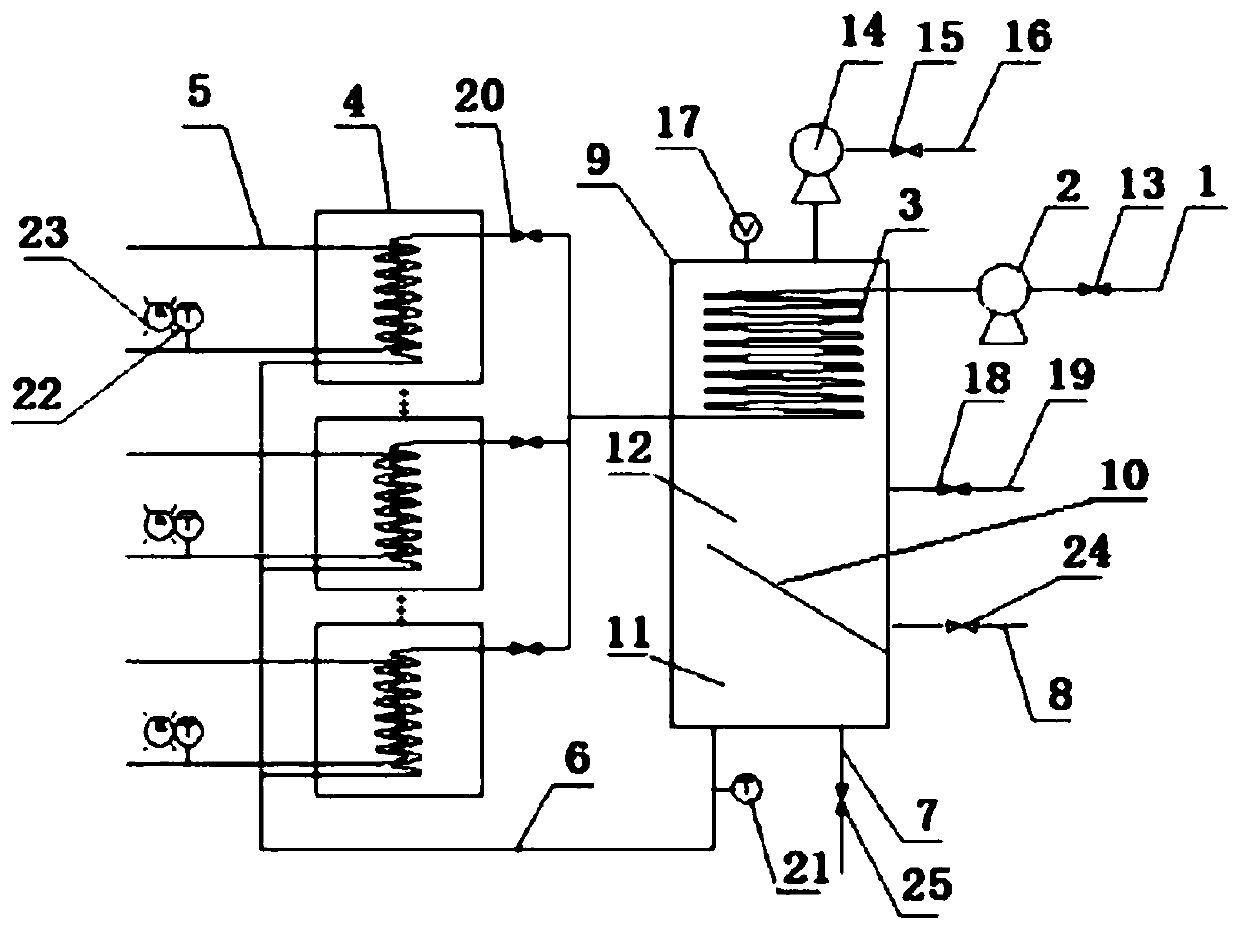

An integrated engine waste heat fresh water device

ActiveCN106335955BReduce dosageReduce in quantityWater treatment parameter controlSeawater treatmentWater cyclingProcess engineering

The invention relates to an integrated engine waste heat device for fresh water production. The integrated engine waste heat device for fresh water production comprises a seawater inlet, a variable-frequency seawater replenishment pump, a seawater preheating heat exchanger, a high-temperature cooling water heat exchanger, a high-temperature cooling water circulating loop and a negative-pressure fresh water production furnace. The seawater inlet is connected with one end of the variable-frequency seawater replenishment pump through a seawater stop valve, the other end of the variable-frequency seawater replenishment pump is connected with the inlet end of the seawater preheating heat exchanger, the outlet end of the seawater preheating heat exchanger is connected with multiple high-temperature cooling water heat exchanger inlets respectively, the inlet end and the outlet end of the high-temperature cooling water circulating loop are connected with an external engine unit, the high-temperature cooling water circulating loop is partially arranged in the high-temperature cooling water heat exchanger, and high-temperature cooling water heat exchanger outlets are communicated with the negative-pressure fresh water production furnace through a seawater loop. The integrated engine waste heat device can simultaneously recover the heat from multiple engine units, the number of waste heat fresh water production devices is decreased, and the energy utilization rate is effectively improved.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

Multi-element mixed working medium regenerative throttling refrigeration cycle system with condensate separation

ActiveCN103822389BImprove efficiencyFlexible layoutCompression machines with non-reversible cycleSuperheatersRefrigeration compressorEngineering

A multi-element mixed working medium back-heating type throttling and refrigerating circulation system with dephlegmator-separator is composed of a compressor module, a back-heating heat exchanger module, a throttling module, an evaporative heat exchanging module and connecting pipes thereof. A high-pressure outlet of the refrigerating compressor module is connected with a refrigerant high-pressure inlet of the back-heating heat exchanger module, a refrigerant high-pressure outlet of the back-heating heat exchanger module is connected with a refrigerant high-pressure inlet of the throttling module, a refrigerant low-pressure inlet of the throttling module is connected with the evaporative heat exchanging module, an outlet of the evaporative heat exchanging module is connected with a refrigerant low-pressure inlet of the back-heating heat exchanger module, a refrigerant low-pressure outlet of the back-heating heat exchanger module is connected with a low-pressure inlet of the refrigerating compressor module. The back-heating heat exchanger module is composed of dephlegmator-separator sub modules from first stage to fifth stage, and the dephlegmator-separator sub module of any stage is of eight different structures. The system can realize refrigeration of fixed temperature zone at a low temperature effectively, and can also be applicable to fields with complicated load, such as multi-element gas liquefied separation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Expansion type heat exchanger

InactiveCN109737770AReduce heat transfer loadRealize mixed cold and heat compensation heat exchangeDirect contact heat exchangersHeat exchanger casingsManufacturing cost reductionExpansion tank

The invention provides an expansion type heat exchanger based on mixed heat exchange. The expansion type heat exchanger comprises an expansion section, a water supply section, a partition, a water supplement port, an inlet, an outlet, a direct mixing heat exchanger, a water distribution mechanism, a filler, an annular weir plate, an automatic exhaust valve and a liquid level sensor. The heat exchanger and an expansion water tank are organically combined, the structure is reasonable and compact, the utilization rate of equipment is increased, the manufacturing cost is lowered, and the occupiedspace is reduced. By the adoption of the expansion type heat exchanger, the mixed cold and hot compensation heat exchange of cold and hot water is realized, the environmental heat exchange load is reduced, and meanwhile water supplement, constant pressure and elimination of system gas or over-filled water are realized. The expansion type heat exchanger is flexible and convenient to use, compact instructure and environmentally-friendly, saves water, saves energy and is widely applicable to cold and hot water supply occasions with different temperature regions and different heat loads.

Owner:QINGDAO UNIV

Method of reducing interstage temperature of propane compressor in propane compressor cycle refrigerating system

ActiveCN102562532BReduce heat transfer loadImprove work efficiencyPositive displacement pump componentsFluid circulation arrangementLow loadEngineering

Owner:CHINA NAT OFFSHORE OIL CORP +1

A desktop self-supply water heat exchanger performance testing device

InactiveCN110806329BAccuracy meetsSatisfy mixed heat and cold compensation heat transferStructural/machines measurementExpansion tankEnergy recovery

The present invention provides a desktop type self-supply water heat exchanger performance test experiment device based on semiconductor heat pump, which utilizes semiconductor heat pump technology, has small volume, flexible control, and adapts to the requirements of desktop systems; realizes energy saving, especially when hot and cold water are supplied at the same time. Compensation, recovery of energy from cold and heat sources; circulating water supply, no need for upper and lower water, convenient and flexible experiments, not limited by the position of upper and lower water pipes; heat exchanger type expansion tank is adopted, bulky cold and hot water tanks are discarded, and the structure is compact, realizing hot and cold water The mixed cold and heat compensation heat exchange reduces the heat exchange load of the environment, and at the same time realizes water replenishment, constant pressure, and removal of system gas or excess water; the flow rate is independently adjusted and is not affected by other factors, and each test condition is easy to achieve; considering downstream and countercurrent test conditions and its influence on the thermodynamic efficiency of energy recovery to maximize energy recovery; use the thermoelectric power generation module for heat recovery, and at the same time realize self-power generation to meet the electricity demand of its own instruments; the invention is flexible and convenient, with a structure Compact, water-saving, environmentally friendly, and energy-saving, it can realize the thermal performance and resistance characteristics testing of liquid-liquid heat exchangers, and is widely applicable to the experimental teaching and testing needs of heat exchangers.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com