Multi-element mixed working medium back-heating type throttling and refrigerating circulation system with dephlegmator-separator

A multi-component mixed working medium, condensate separation technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficulty in further improving the efficiency of refrigeration systems, increasing the manufacturing cost of refrigerators, difficulty in high efficiency, and universal adaptation. Achieve the effects of flexible layout, reduced heat transfer load, and improved heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A multi-element mixed working fluid regenerative throttling refrigeration cycle system with 5-stage fractional condensation and separation sub-modules

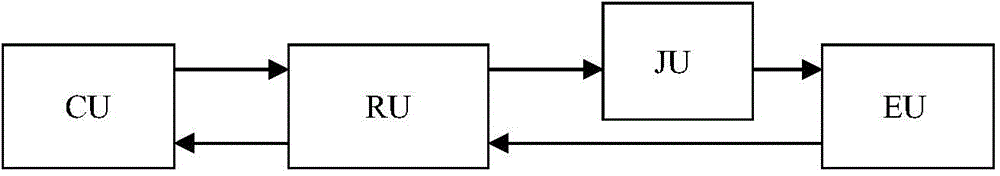

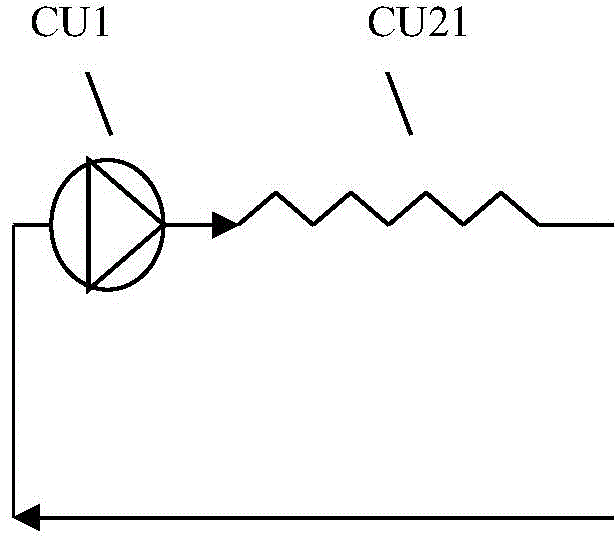

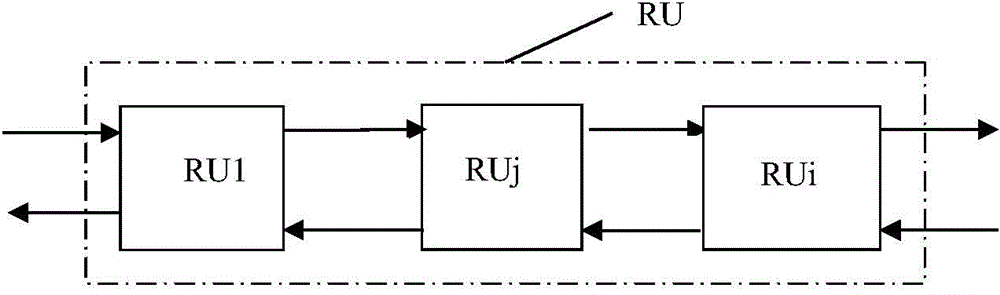

[0038] figure 1 It is a schematic diagram of the structure of the circulation system in the present invention; figure 2 It is a schematic diagram of the structure of a compressor module CU; image 3 It is a schematic diagram of the structure of the regenerative heat exchange module RU in the present invention; Figure 4 It is a schematic diagram of the flow structure of the first sub-module S1 of fractionation and separation in the present invention; figure 1 , figure 2 , image 3 with Figure 4 It can be seen that the multi-element mixed working fluid regenerative throttling refrigeration cycle system with separation and separation provided by the present invention consists of a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, an evaporative heat exchange module EU and its...

Embodiment 2

[0046] Embodiment 2: A multi-element mixed working fluid regenerative throttling refrigeration cycle system with 4-stage fractional condensation and separation sub-modules

[0047] Such as figure 1 As shown, a multi-component mixed working fluid regenerative throttling refrigeration cycle system with separation and condensation consists of a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, an evaporative heat exchange module EU and its connecting pipes Circuit composition, compressor module such as Figure 5 As shown; its regenerative heat exchange unit RU is composed of four-stage sub-condensation separation sub-modules RU1 to RU4, RU1 adopts the S6 structure of the sub-condensation separation sub-module process, RU2 adopts the S3 structure of the sub-condensation separation sub-module, and RU3 uses the separation sub-module The S2 structure of the ion separation module, RU4 adopts the structure of the separation sub-module S1; the connection...

Embodiment 3

[0049] Example 3: A multi-element mixed working fluid regenerative throttling refrigeration cycle system with a 3-stage fractional condensation and separation sub-module

[0050] Such as figure 1 As shown, a multi-component mixed working fluid regenerative throttling refrigeration cycle system with separation and condensation consists of a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, an evaporative heat exchange module EU and its connecting pipes. Circuit composition, compressor module such as Figure 5 As shown; its regenerative heat exchange unit RU is composed of three-stage sub-condensation separation sub-modules RU1 to RU3, RU1 adopts the structure of sub-condensation separation sub-module S6, RU2 adopts the structure of sub-condensation separation sub-module S8, and RU3 adopts sub-condensation separation sub-module S2 structure; its connection method is: the high-pressure outlet of the refrigeration compressor module CU is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com