A co-production system and method for recovering light hydrocarbons from helium-depleted natural gas and extracting helium

A light hydrocarbon recovery and natural gas technology, which is applied in gas fuel, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of high energy consumption of the device, insufficient process integration, low thermal design efficiency, etc., and achieve the improvement of crude helium Concentration, strong flexibility, and the effect of a small number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

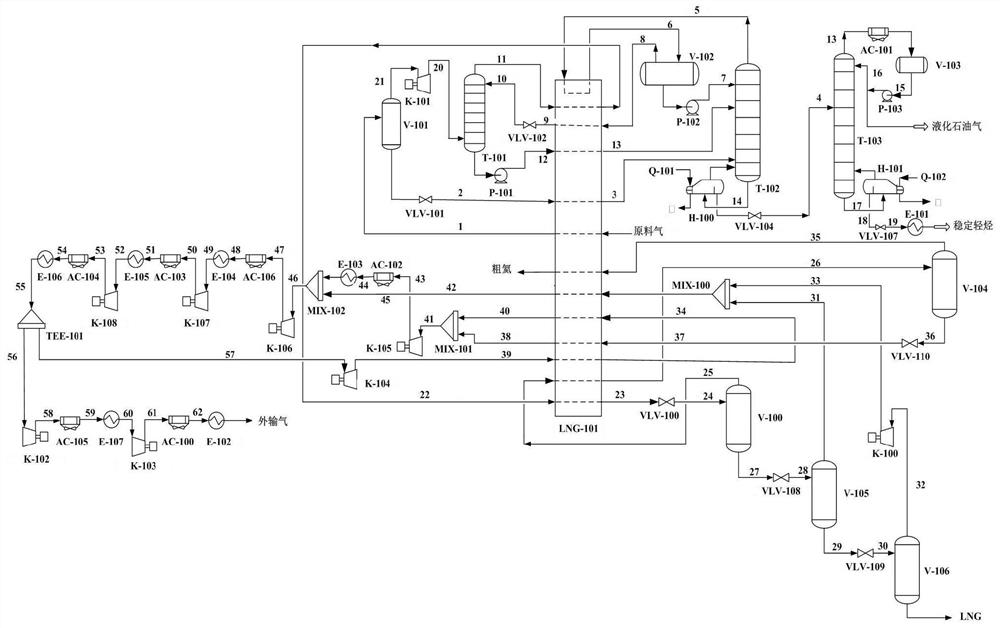

Method used

Image

Examples

Embodiment 1

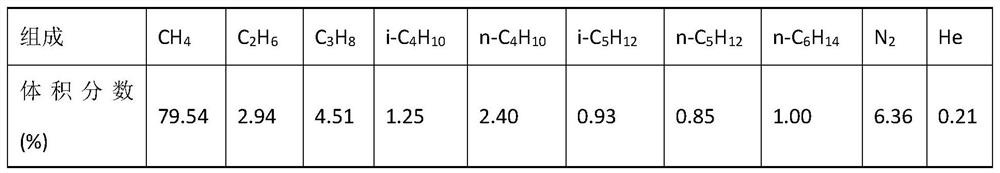

[0047] The gas composition of the raw material gas is shown in Table 1 and the working conditions:

[0048] Raw material gas processing capacity: 5.0×10 5 N m 3 / d

[0049] Raw gas pressure: 6MPa

[0050] Entry temperature: 20°C

[0051] Product quality requirements:

[0052] Saturation vapor pressure of liquefied petroleum gas: P≤1430kPa

[0053] Saturation vapor pressure of stable light hydrocarbons: 74kPa≤P≤200kPa, final boiling point of stable light hydrocarbons: T≤190℃

[0054] Table 1 Feed gas composition

[0055]

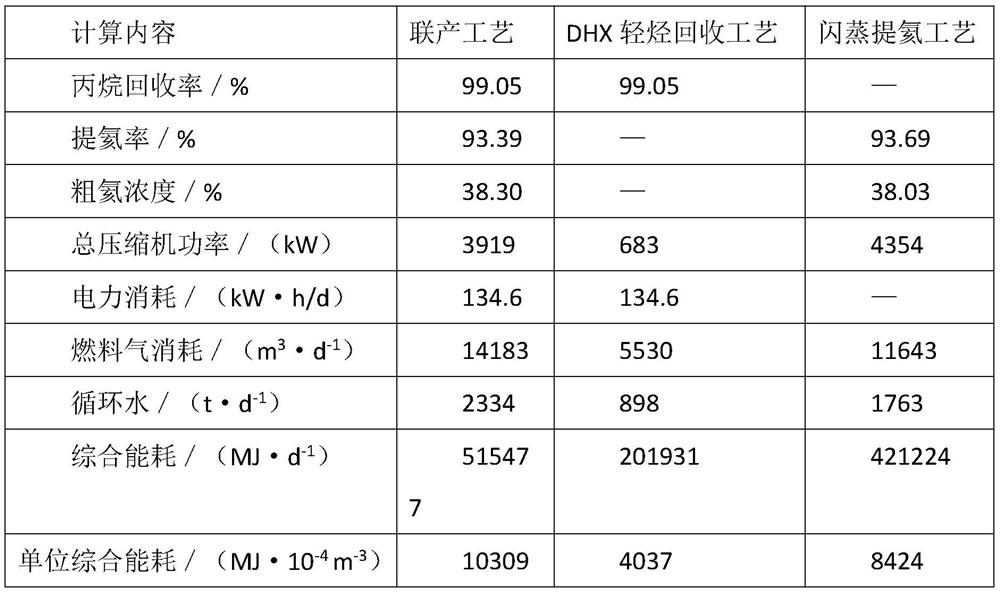

[0056] Economic data such as product yield and energy consumption and thermodynamic data are mainly used to make a comprehensive comparison between the cogeneration system of the present invention and a single process. The recovery rate and energy consumption comparison results are shown in Table 2. See Table 3 for temperature difference, minimum heat transfer temperature difference and load comparison.

[0057] Table 2 recovery rate and energy co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com