A booster-type drainage gas production device for the "snake-curved" horizontal section of a horizontal well

A technology for water drainage and gas recovery and horizontal section, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., and can solve the problem of blocked gas flow channels, drainage and gas recovery technology that is difficult to lower into the horizontal section, drainage and gas recovery devices and Less research on tools and other issues can achieve the effect of accelerating the discharge rate, improving the efficiency of drainage and gas recovery, and ensuring normal production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

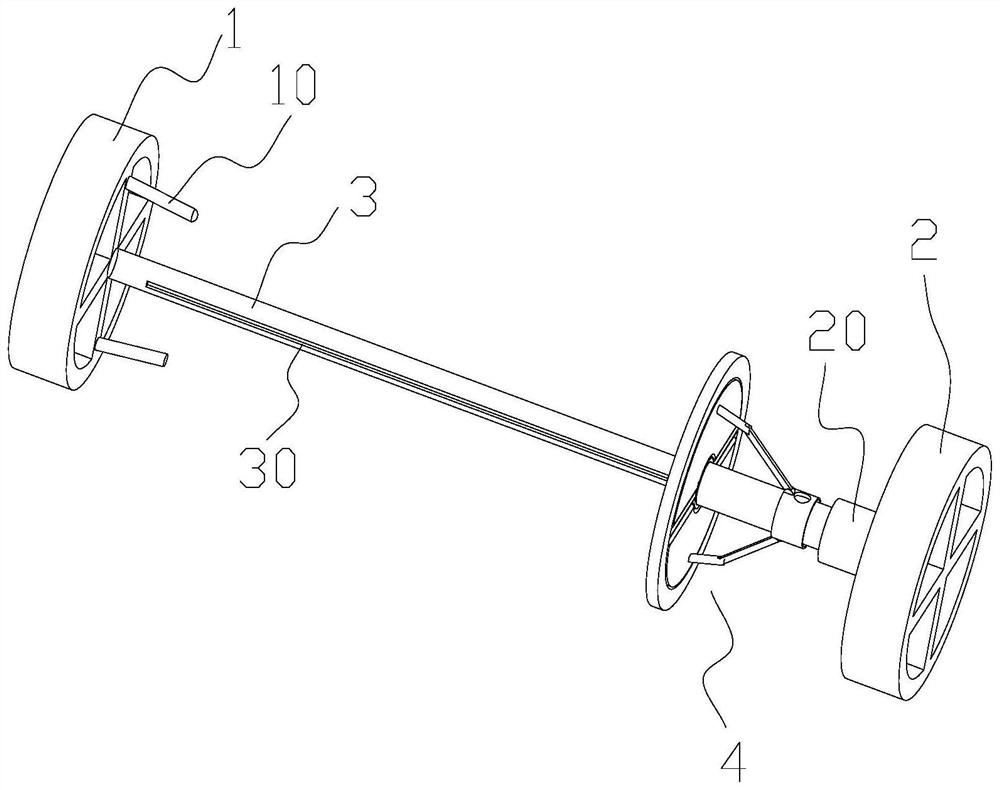

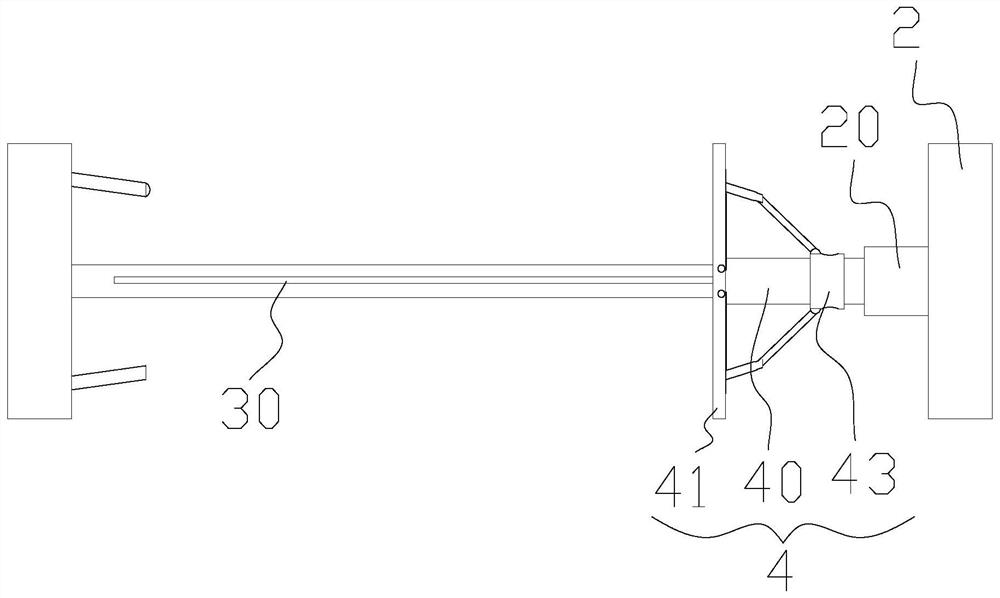

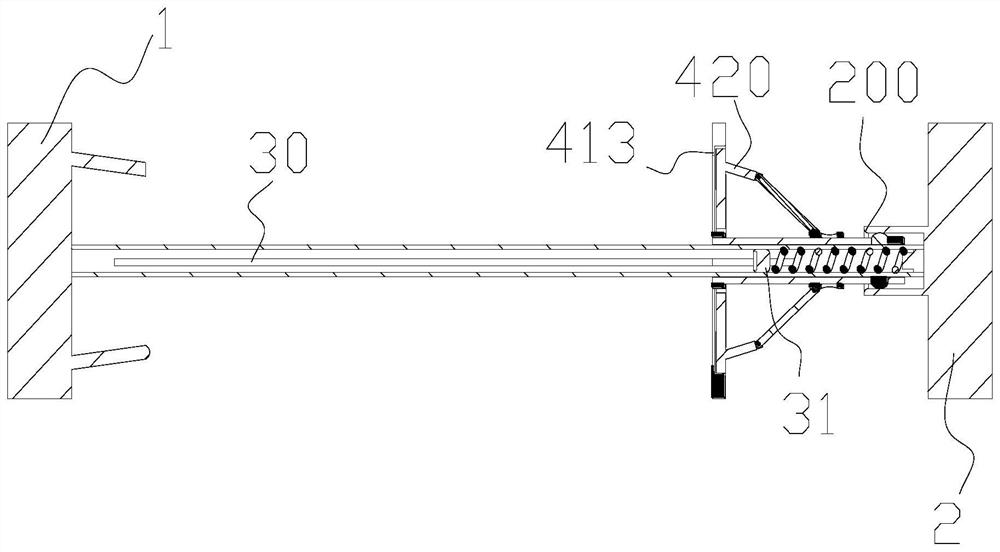

[0034] refer to Figure 1 to Figure 9 A booster drainage and gas recovery device for the "serpentine" horizontal section of a horizontal well as shown, includes a front fixing seat 1 and a rear fixing seat 2 facing each other, and the two ends are connected with the front fixing seat 1 and the rear fixing seat 2 respectively. The installation shaft 3 connected to the thick fixed seat 2 (the front, back, left and right, and up and down directions in this application are all based on the position in the horizontal section during use as a reference, and the back is close to the bottom of the well, the front is close to the wellhead, and the bottom is close to the lower side wall of the wellbore. , the upper side wall is the upper), as shown in the figure, the main structures of the front fixing seat 1 and the rear fixing seat 2 in this embodiment are consistent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com