Iterative cooling system refrigerated via mixed work medium for throttling and low temperature eddy expansion

A multi-component mixed working fluid, expansion refrigeration technology, applied in refrigerators, refrigeration and liquefaction, compressors with cascade work, etc., can solve the problems of easily blocked throttling elements, such as refrigeration temperature, fluctuation, and inability to operate effectively. To achieve the effect of reducing heat exchange load, low vibration, and improving heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

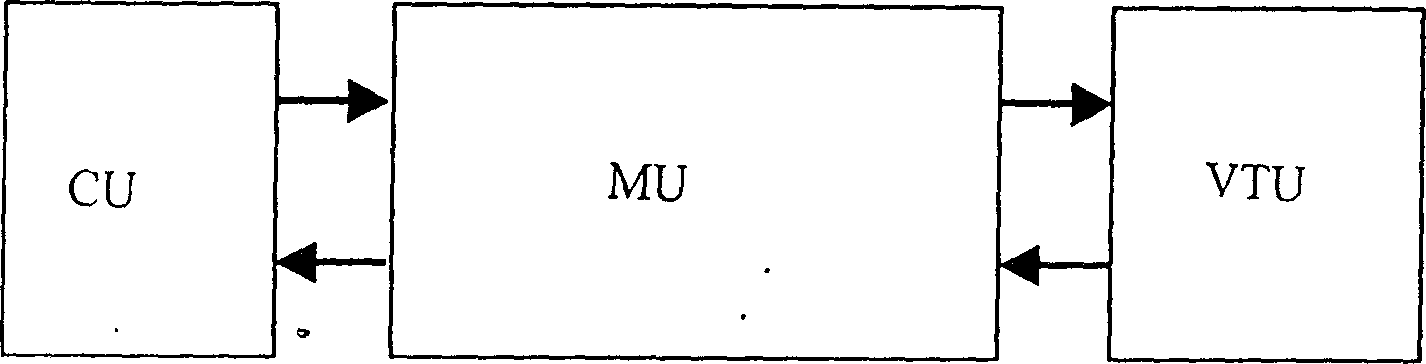

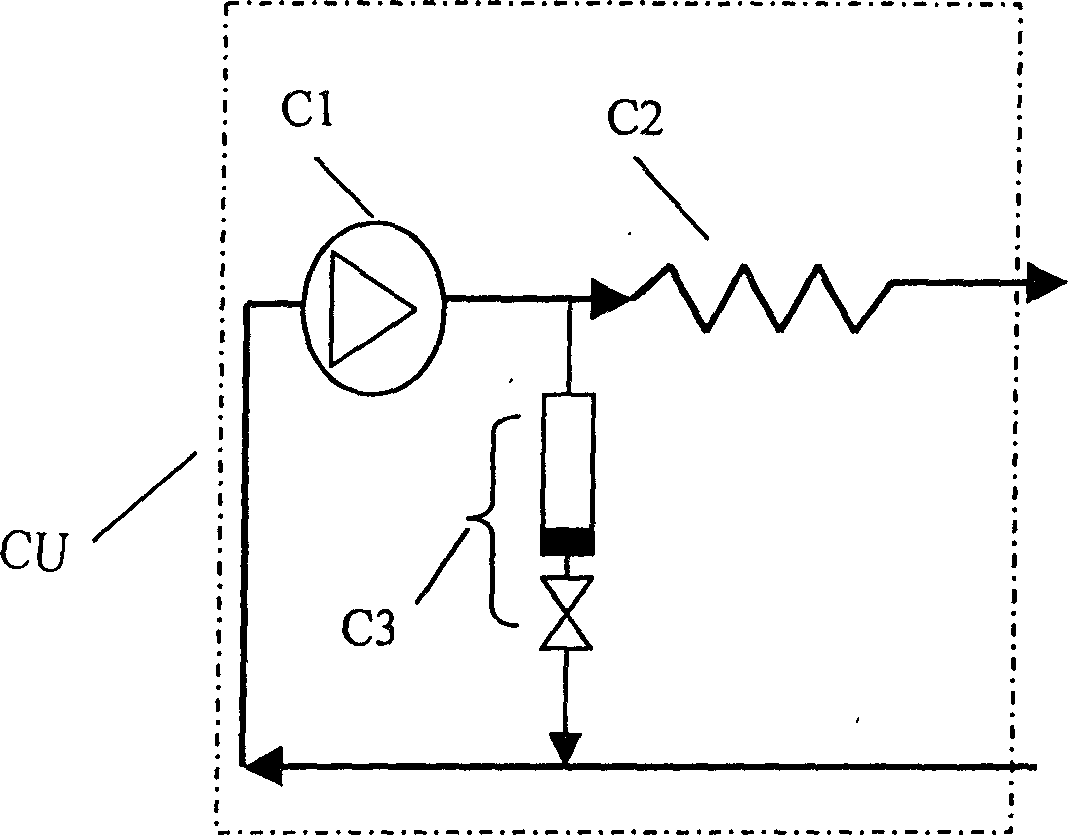

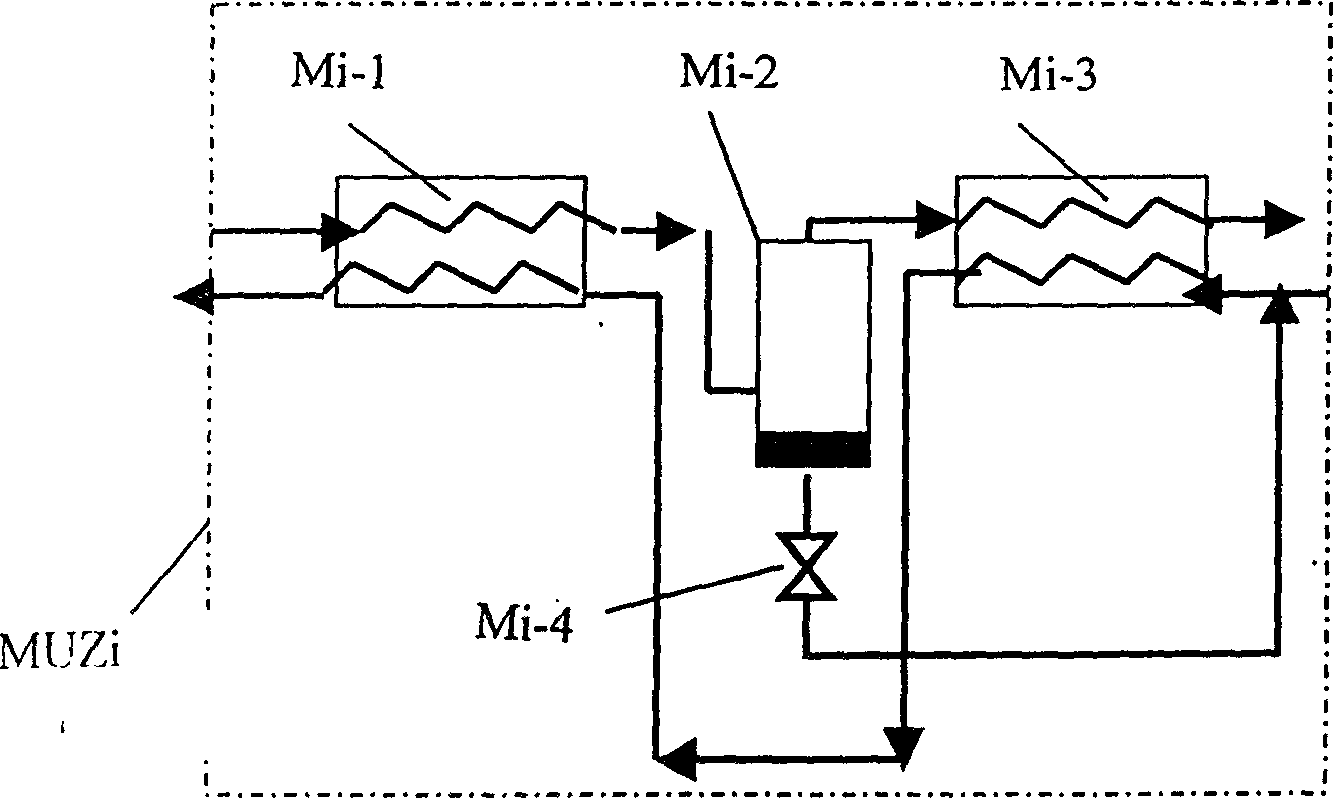

[0038] Embodiment 1: The composite cycle refrigeration system of multi-element mixed working fluid throttling refrigeration and vortex expansion refrigeration of the present invention driven by a single-stage oil-lubricated air-conditioning compressor can reach a temperature range of 30K-60K, and its structural block diagram is shown in figure 1 , the structural diagram of the compressor module CU is shown in figure 2 , the mixed refrigerant intermediate throttling refrigeration module VTU adopts a two-stage multi-element mixed refrigerant sub-module MUZ, and the structure diagram of the first-stage multi-element mixed refrigerant sub-module MUZi is shown in image 3 , the structural diagram of the second-stage multi-element mixed refrigerant sub-module MUZ is shown in Figure 4 , the structural illustration of the vortex tube refrigeration module VTU Figure 5 ;Depend on figure 1 It can be seen that the connection mode of each component in this embodiment is: the outlet of...

Embodiment 2

[0039] Embodiment 2: The structural block diagram of the composite cycle refrigeration system of multi-element mixed working fluid throttling refrigeration and vortex expansion refrigeration reaching the temperature range of 20K in the present invention is shown in figure 1 , the structure diagram of the compressor module CU is shown in figure 2 , the mixed working medium throttling refrigeration module MU adopts a two-stage multi-component mixed working medium refrigeration sub-module MUZ, and its structure is shown in image 3 , the structure of the vortex tube refrigeration module VTU see Figure 5 ,Depend on figure 1 It can be seen that the structure of this embodiment is as follows: the outlet of the high-pressure pipe of the compressor module CU is connected to the high-pressure inlet pipe of the intermediate refrigeration module MU, and the low-pressure inlet pipe of the compressor module CU is connected to the low-pressure outlet pipe of the mixed working medium thro...

Embodiment 3

[0040] Embodiment 3: The multi-element refrigeration and vortex expansion refrigeration compound cycle refrigeration system that uses the present invention to reach the liquid helium temperature zone, its structural block diagram is shown in figure 1 , the structure of the compressor module CU is the same as in Embodiment 1, and the compressor adopts a single-stage oil-lubricated air-conditioning compressor (R22 compressor) of 2.5kW; the structure of the vortex tube refrigeration module VTU is the same as in Embodiment 1; the intermediate refrigeration module adopts three stages Multi-element mixed refrigerant sub-module, wherein the structures of the first-stage multi-element mixed refrigerant sub-module and the second-stage multi-element mixed refrigerant sub-module are the same as those of the first-stage multi-element mixed refrigerant sub-module and the second The second-level multi-component mixed refrigerant sub-module, the structure of the third-level multi-component mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com