Method of reducing interstage temperature of propane compressor in propane compressor cycle refrigerating system

A refrigeration system and compressor stage technology, which is applied in the fields of natural gas liquefaction and cryogenic air separation, can solve the problems of reduced compressor efficiency and increased power consumption, and achieve the effects of reducing heat transfer load, eliminating influence, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

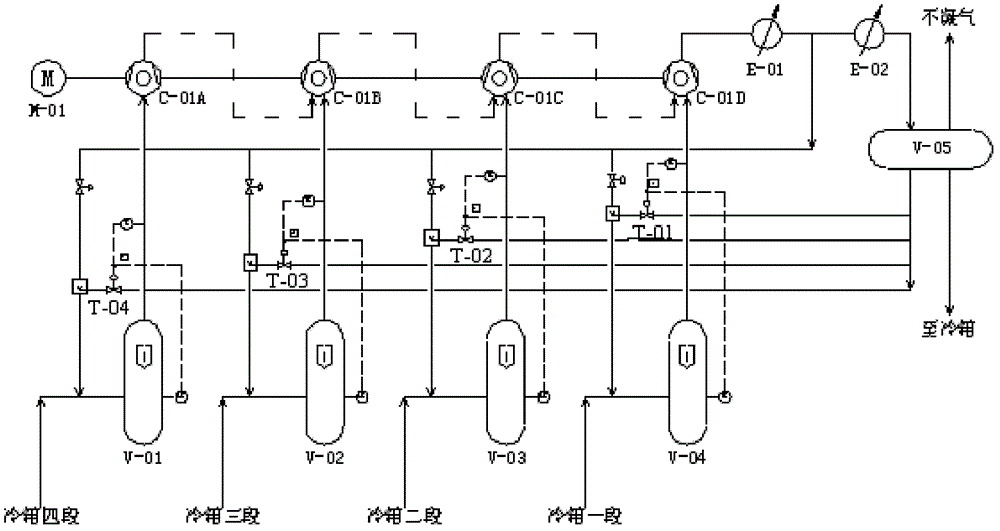

[0012] Embodiment 1, reduce compressor interstage temperature

[0013] The raw natural gas liquefaction of a gas field, the raw gas composition is 94.94% methane, 2.33% ethylene, 1.95% nitrogen, 0.52% propane, 0.13% butane, 0.12% isobutane; the annual output of the device is 2.6 million tons of LNG, Pre-cooled by four-stage propane, then enters into liquefaction, deep cooling, throttling and cooling, it becomes liquefied natural gas and enters the storage tank; propane enters the propane compressor and is compressed in four stages, then enters the cooler E-01 to cool to 45°C, and the condenser E-02 condenses to 41°C.

[0014] In this propane compressor cycle refrigeration system, the temperature and pressure of the propane returned from the pre-cooling cold box to the buffer tank V-01 of the first-stage compressor in the fourth stage are -36.9°C and 109kPaA respectively; the three-stage return of the cold box to the second-stage compressor The temperature and pressure of the ...

Embodiment 2

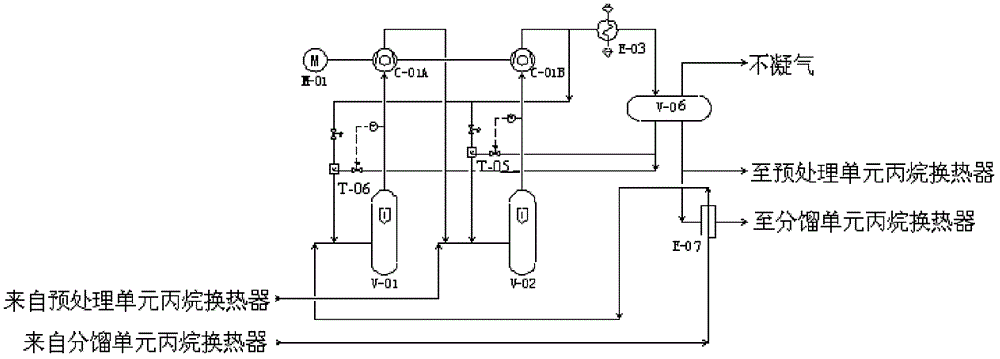

[0016] Embodiment 2, reduce compressor interstage temperature

[0017] A natural gas processing unit is equipped with an independent propane compressor circulating refrigeration system, which is designed to provide the necessary cooling load for the fractionation unit of the processing unit and its supporting pretreatment unit. Low-pressure propane refrigerant (temperature -8.56°C, pressure 2.05 barg) passes through the high-low pressure propane heat exchanger E-07 for heat exchange, and then enters the first-stage propane compressor C-01A through the primary inlet buffer tank V-01 of the compressor to be compressed to 6.18barg, the medium-pressure propane (temperature -16.61℃, pressure 6.18barg) from the propane heat exchanger of the pretreatment unit is mixed with the refrigerant from the C-01A outlet of the primary propane compressor and then enters the secondary inlet buffer of the propane compressor The tank V-02 is compressed by the secondary propane compressor C-01B, th...

Embodiment 3

[0020] Embodiment 3, reduce compressor interstage temperature

[0021] The raw material natural gas liquefaction of a gas field in a cold region adopts the same process as in Example 1; the temperature of the cooling medium decreases, propane enters the propane compressor and is compressed in four stages, and then enters the cooler E-01 to cool to 23°C, and the condenser E- 02 condenses to 19°C.

[0022] In this propane compressor cycle refrigeration system, the temperatures of the propane returned to the compressor inlet buffer tanks V-01 to V-04 from the fourth section to the first section of the pre-cooling cold box are respectively -36.9°C, -21.6°C, -6.3°C and 7.4°C ℃.

[0023] When the propane compressor cycle refrigeration system operates at low load, the pre-cooling compressors (propane compressors C-01A, C-01B, C-01C and C-01D) need to lead back the propane gas from the cooler E-01 Perform surge reflux; the temperatures of the anti-surge reflux propane gas entering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com