Low-temperature gas liquefaction and separation system applying effect of segregation

A technology for liquefaction separation and segregation separation, which is applied in the field of low-temperature gas liquefaction separation systems and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: prepare the gas cryogenic liquefaction separation system of a 1-stage separation, for containing ethylene (C 2 h 4 ) and C 3+ Ethylene gas and C in the chemical tail gas of hydrocarbons 3+ Recovery of hydrocarbons.

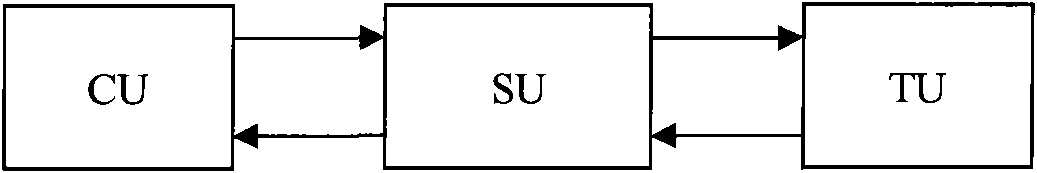

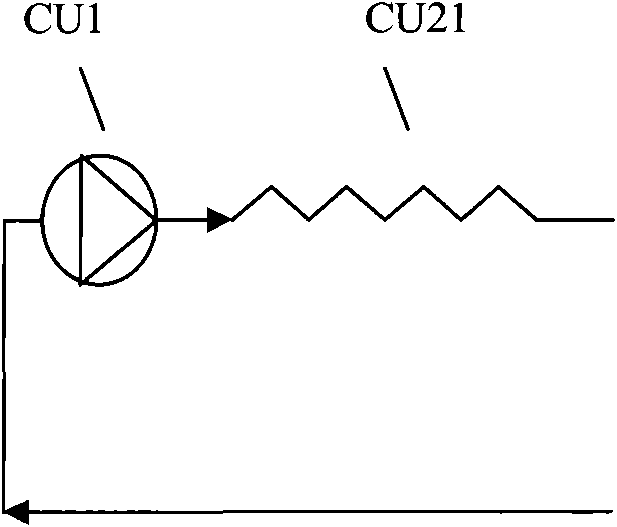

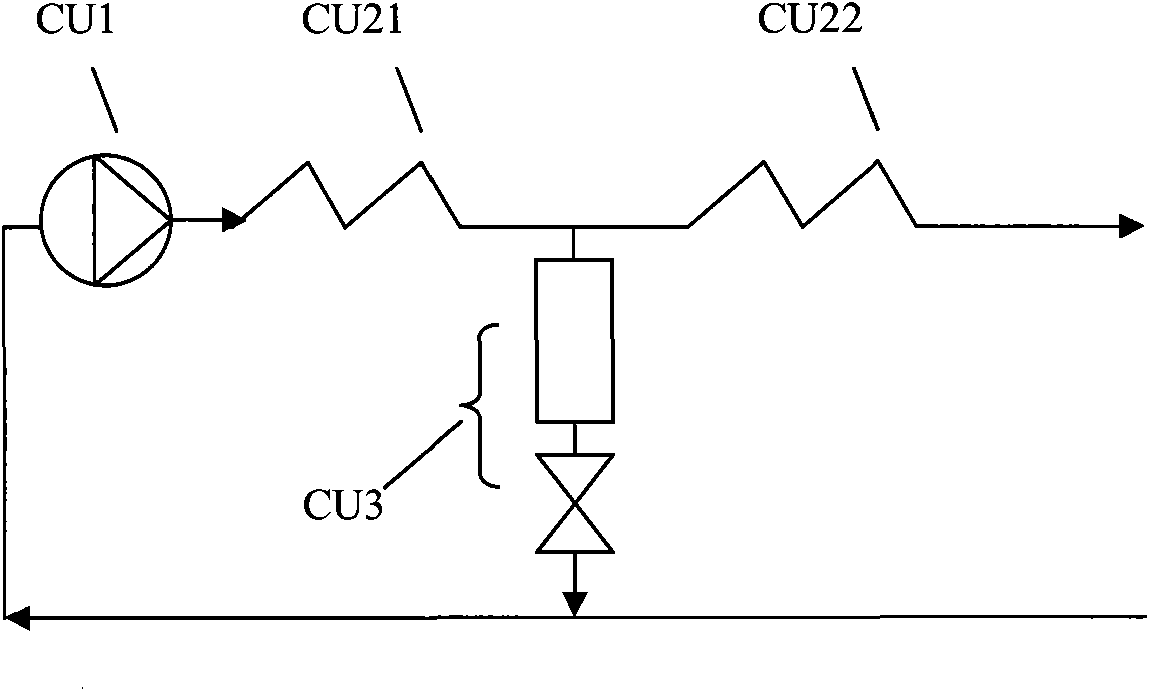

[0046] The general connection method of the separation system can be found in figure 1, The compressor module CU adopts Figure 1.1 The structure shown; the cooling segregation and separation module can adopt the first cooling segregation sub-module S1, the second cooling segregation sub-module S2, the third cooling segregation sub-module S3 or the fourth cooling segregation sub-module S4 , the present embodiment adopts the fourth cooling sub-condensation sub-module S4 (see Figure 2.4 ); the liquefaction separation module TU adopts Figure 3.5 The structure shown; the connection mode of the refrigeration system is: the high-pressure outlet of the compressor module CU is connected to the high-pressure refrigerant inlet of the fourth coo...

Embodiment 2

[0048] Embodiment 2: prepare the gas cryogenic liquefaction separation system of a 1-level separation, for containing ethylene (C 2 h 4 ) and C 3+ Ethylene gas and C in the chemical tail gas of hydrocarbons 3+ Recovery of hydrocarbons. The general connection method of the separation system can be found in figure 1, Wherein the compressor module and the cooling segregation and separation module are the same as those in Embodiment 1, and the liquefaction separation module TU adopts Figure 3.6 The structure shown, the connection mode of the refrigeration system and the separated gas pipeline are the same as those in Embodiment 1.

[0049] In the cooling and condensing separation module of the system, the components containing three or more carbon atoms in the chemical tail gas are cooled at a low temperature and discharged as liquids, and the unliquefied gas enters the liquefaction separation module TU; in TU, ethylene is liquefied and separated, After the unliquefied tail...

Embodiment 3

[0050] Example 3: A gas low-temperature liquefaction separation system with two stages of separation is prepared for the liquefaction of coalbed methane. The general connection method of the system can be found in figure 1, Wherein the compressor module is the same as in embodiment 1, and the liquefaction separation module TU adopts Figure 3.1 structure shown. The cooling segregation and separation module SU is composed of 2-stage cooling segregation and separation sub-modules SU1 and SU2. The third cooling sub-condensation sub-module S3, the fourth cooling sub-condensation sub-module S4 or any combination thereof. In this example, the sub-module SU1 for cooling and decondensation adopts the second sub-module for cooling and decondensation S2 (see Figure 2.2 ); the sub-module SU2 for cooling and segregation adopts the third sub-module for cooling and condensing S3 (see Figure 2.3 ). The connection mode of the refrigeration system is: the high-pressure outlet of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com