Low-temperature gas liquefaction and separation system applying effect of segregation

A technology of liquefaction separation and condensate separation, which is applied in the field of gas low-temperature liquefaction separation system, and can solve problems such as complex structure

Active Publication Date: 2011-01-05

TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problems of complex structure in the commonly used low-temperature liquefaction separation process, the patent of the present invention proposes a gas liquefaction separation system using the effect of segregation condensation separation, which has the advantages of simple equipment, safe and reliable operation, low energy consumption, and does not include a stripping tower / Distillation tower and other large and complex equipment, and the separation effect can meet the requirements and low cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

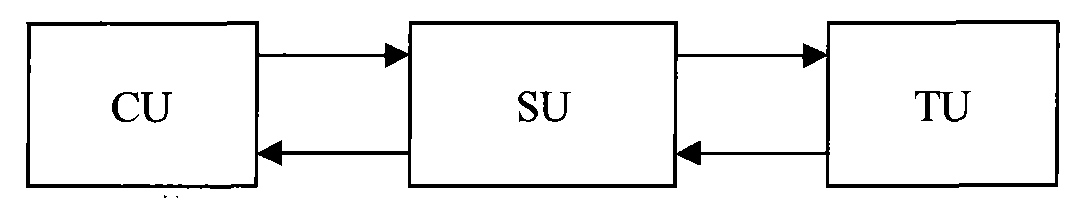

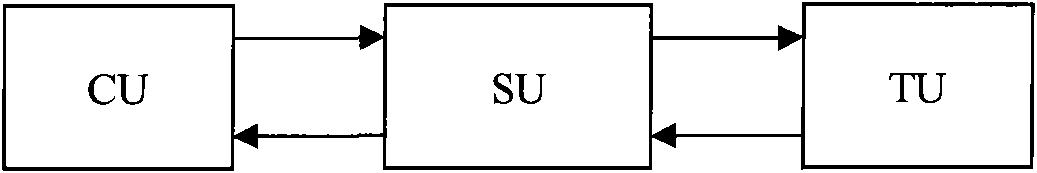

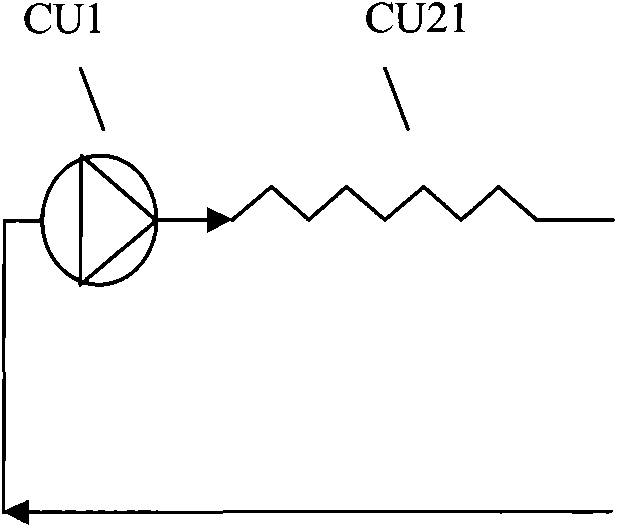

The invention relates to a low-temperature gas liquefaction and separation system applying the effect of segregation, which comprises a compressor module, a cooling and segregation module and a liquefaction and separation module, wherein a high-pressure outlet of the compressor module is connected with a refrigerant high-pressure inlet of the cooling and segregation module; a refrigerant high-pressure outlet of the cooling and segregation module is connected with a refrigerant high-pressure inlet of the liquefaction and separation module; a refrigerant low-pressure outlet of the liquefaction and separation module is connected with a refrigerant low-pressure inlet of the liquefaction and separation module, and a refrigerant low-pressure outlet of the cooling and segregation module is connected with a lower-pressure inlet of the compressor module; after pretreatment, mixed gas required to be separated enters the cooling and segregation module from a separated gas inlet and then enters the liquefaction and separation module; liquid separated out by each stage and tail gas output by an end stage enters respective preceding stages as required, and cold energy is recovered stage by stage or directly output. The system is driven by a single compressor so as to have reliable and simple operation, applies the segregation to realize separation in a heat exchanger and has simple structure and flexible arrangement.

Description

A low-temperature gas liquefaction separation system using segregation condensation separation effect technical field The invention relates to a gas low-temperature liquefaction separation system, in particular to a gas low-temperature liquefaction separation system using the segregation condensation separation effect. Background technique Natural gas, coke oven gas, coal bed methane and some chemical tail gases are very important energy and resources. If these gases can be fully developed and utilized, it will be of great significance for alleviating the increasingly tense energy and environmental pressure and improving the utilization efficiency of resources. Usually these gases have complex components and are multi-component mixtures. In order to make rational use of these gases and facilitate storage and transportation, liquefaction and separation have become an important technical means, especially for gas sources that are not suitable for pipeline transportation , su...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F25J3/00

Inventor 吴剑峰公茂琼董学强

Owner TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com