Multistage method for dehumidifying liquid

A liquid dehumidification and liquid technology, applied in separation methods, chemical instruments and methods, heating methods, etc., can solve the problems of large volume of dehumidifiers, large heat transfer load, and reduced efficiency of regenerators, and achieve small heat and mass transfer areas , Low gas dew point, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

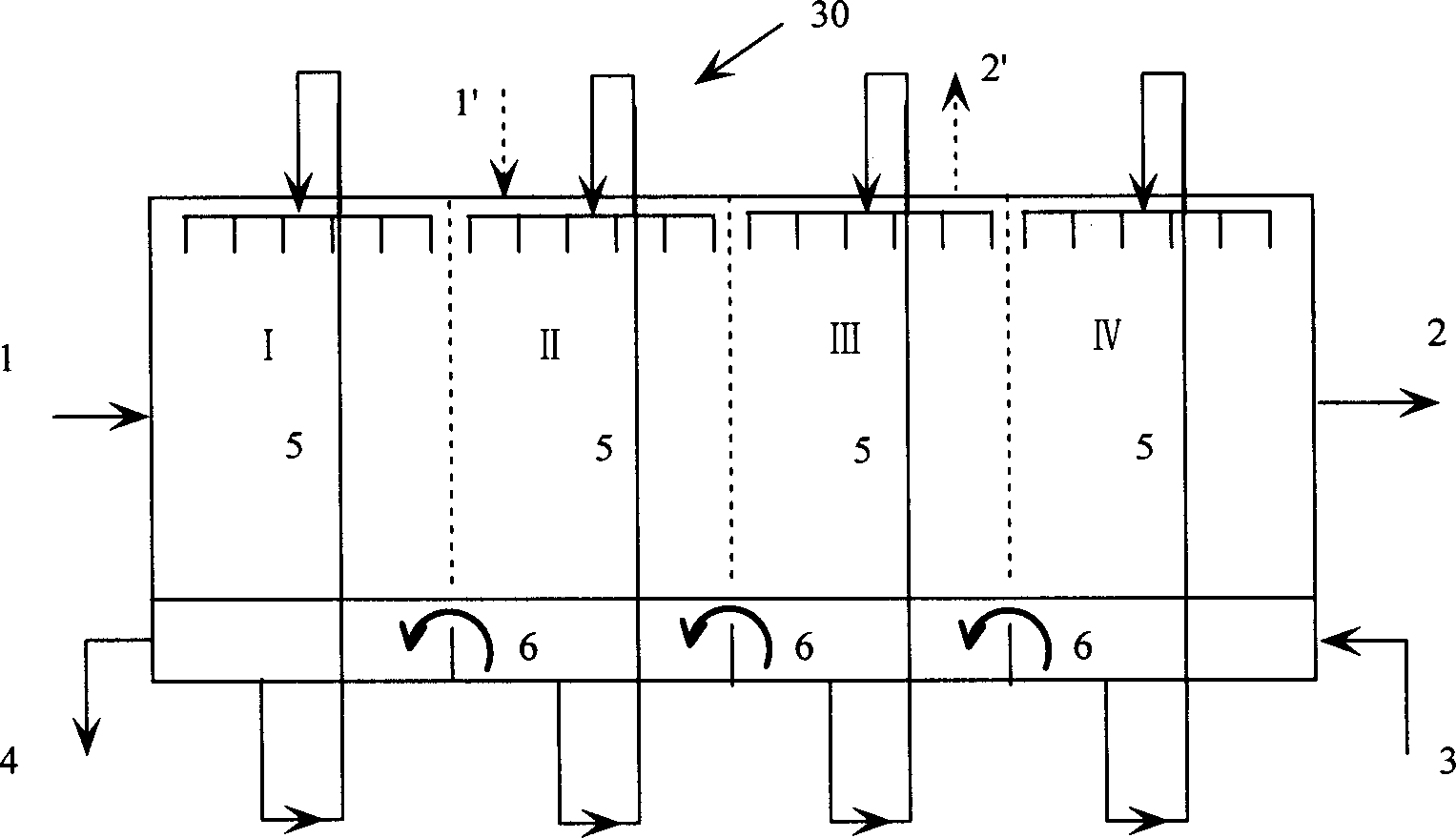

[0031] Below in conjunction with accompanying drawing, prior art and specific embodiment of the present invention will be further described:

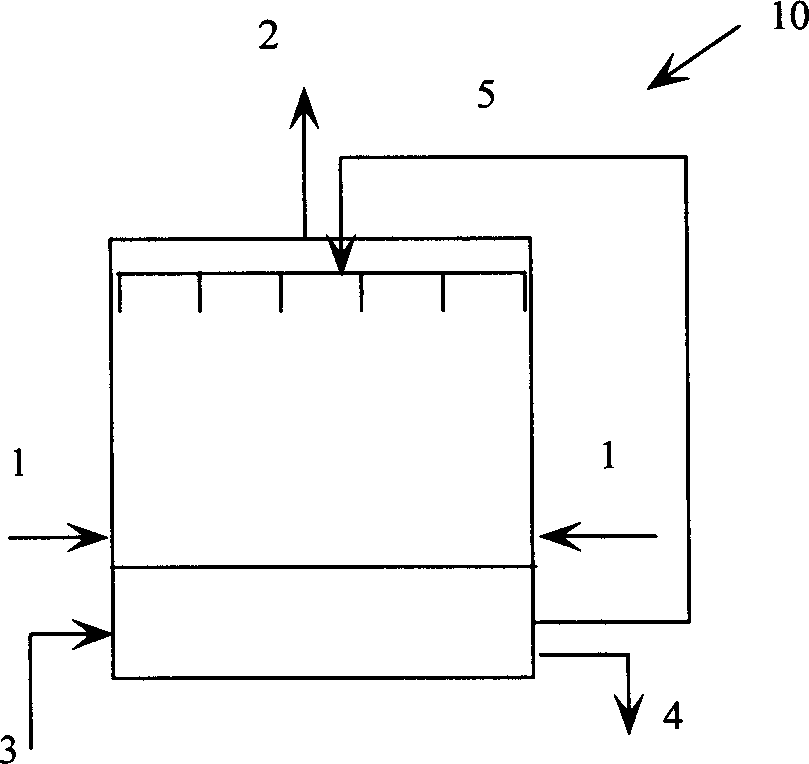

[0032] figure 1 and figure 2 It is a schematic diagram of a typical first-stage liquid dehumidification in the prior art. figure 1 It is a way of gas-liquid countercurrent contact, and the circulating liquid 5 in the figure can be cooled by a cooling medium, which is not shown in the figure. It can be seen from the figure that since the circulating liquid 5 is circulating, although the gas and liquid are in countercurrent contact, the dehumidification has not achieved real countercurrent mass transfer.

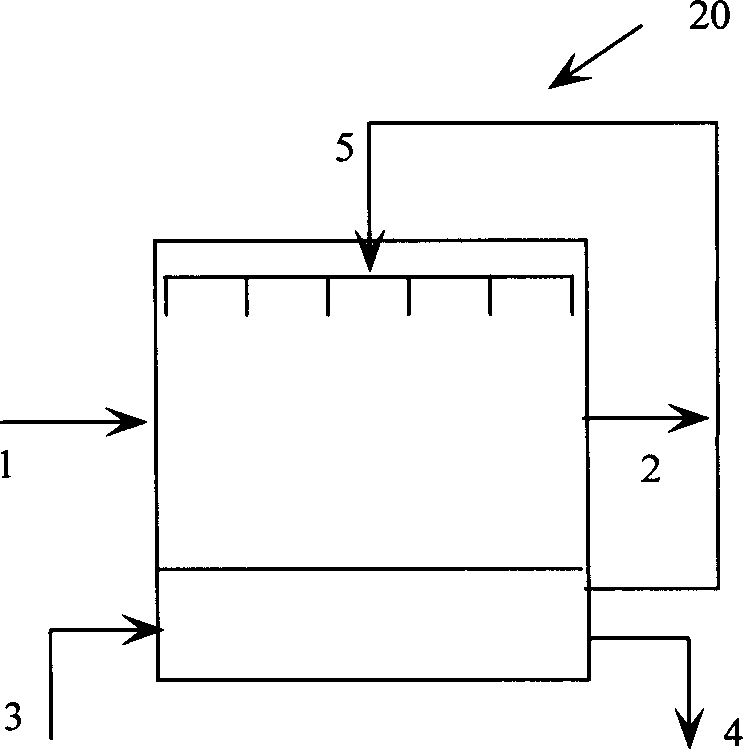

[0033] figure 2 It is the way of gas-liquid cross-flow contact, and of course it is even more impossible to realize countercurrent heat and mass transfer.

[0034] It should be noted that the flow rate of the circulating liquid 5 is several times or an order of magnitude larger than the flow rate of the concentrated solution 3 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com