Continuous synthesis system and method of dicyandiamide

A technology for chemical synthesis and dicyandiamide, applied in the field of continuous dicyandiamide synthesis system, can solve problems such as low product production efficiency, and achieve the effects of reducing product yield, reducing heat exchange load and facilitating temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

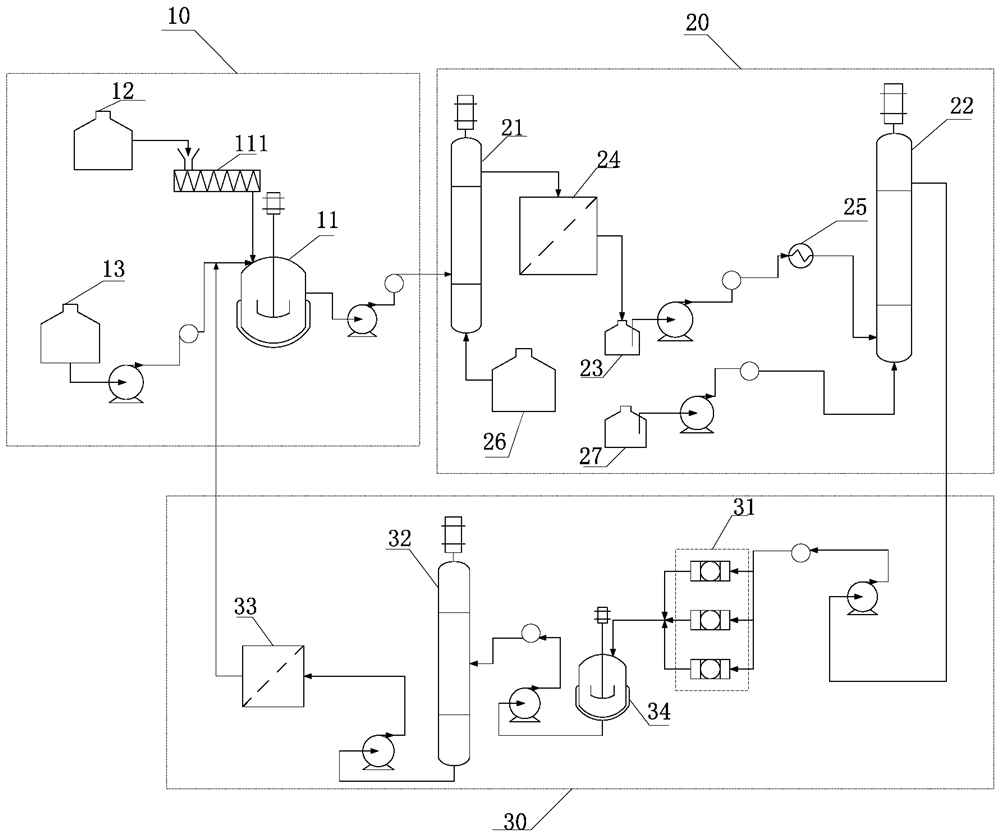

[0057] The present invention also provides a continuous synthesis method of dicyandiamide, and the continuous synthesis method is prepared by the continuous synthesis system of the aforementioned dicyandiamide, and the continuous synthetic method comprises: continuously conveying water and lime nitrogen. The raw material pre-processor 11 is premixed to obtain a premixed material; the premixing material and carbon dioxide are continuously delivered to the hydrolysis of the decallization reactor 21 for hydrolysis, obtaining the hydrolysis of decalcium reactive reactive materials; The material is continuously delivered to the polymerization reactor 22 for polymerization to obtain dicyandiamide.

[0058] The continuous synthesis method of the above-described above-described dicyandiamide is presence:

[0059] 2CACN 2 + 2h 2 O = ca (HCN 2 ) 2 + CA (OH) 2

[0060] CA (HCN 2 ) 2 + 2h 2 O = 2h 2 CN 2 + CA (OH) 2

[0061] 2CA (HCN 2 ) 2 + H 2 O + CO 2 = 2h 2 CN 2 + Caco 3

[0062] CO 2 ...

Embodiment 1

[0073] use figure 1 The system is synthesized. Among them, the hydrolysis of the decalcium reactor is a fin reactor, the fin reactor includes 12 sets of fins, and the height of each set of fins is 15 mm, the thickness is 5 mm, and the spacing of each set of fins is controlled at 25 mm.

[0074] The raw material lime nitrogen with water was continuously input according to 1: 25 (mol).

[0075] The internal temperature of the hydrolysis decalcium reaction column is controlled at 30 to 40 ° C, and the reactive material residence time is about 70 to 80 min, and the material is hydrolyzed and the material enters the third filtration device, and the filter cake is collected by water, the filtrate and the liquid are removed. The merger, by transferring the pump into the polymerization reactor, the reaction temperature is 60 to 70 ° C, the reaction residence time is about 100 to 110 minutes, and the online pH control system is used to ensure the polymerization stage system pH is from 7 to...

Embodiment 2

[0079] And the difference between Example 1 is only:

[0080] The raw material lime nitrogen with water was continuously input according to 1: 25 (mol), and the residence time was about 10 min, and the solid-liquid mixing system of the pre-treated raw material was entered into the hydrolyzate reactor by the transfer pump.

[0081] From the continuous synthesis device, the reaction effect is sampling. The content of the cyanide in the system in the system is about 11.5%, and the purity of the product is 98.2%, and the average reaction yield is 77.4% after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com