Method for controlling igniter burner of powdered coal pressurized gasifier

A pulverized coal pressurized gasification and ignition burner technology, applied in the direction of granular/powdered fuel gasification, gasification process, combined combustion mitigation, etc., can solve the problem of restricting the development of hot fireplaces, great environmental hazards, and inability to realize gasification Problems such as long-term and efficient operation of the device can save driving time and costs, and improve ignition success rate and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

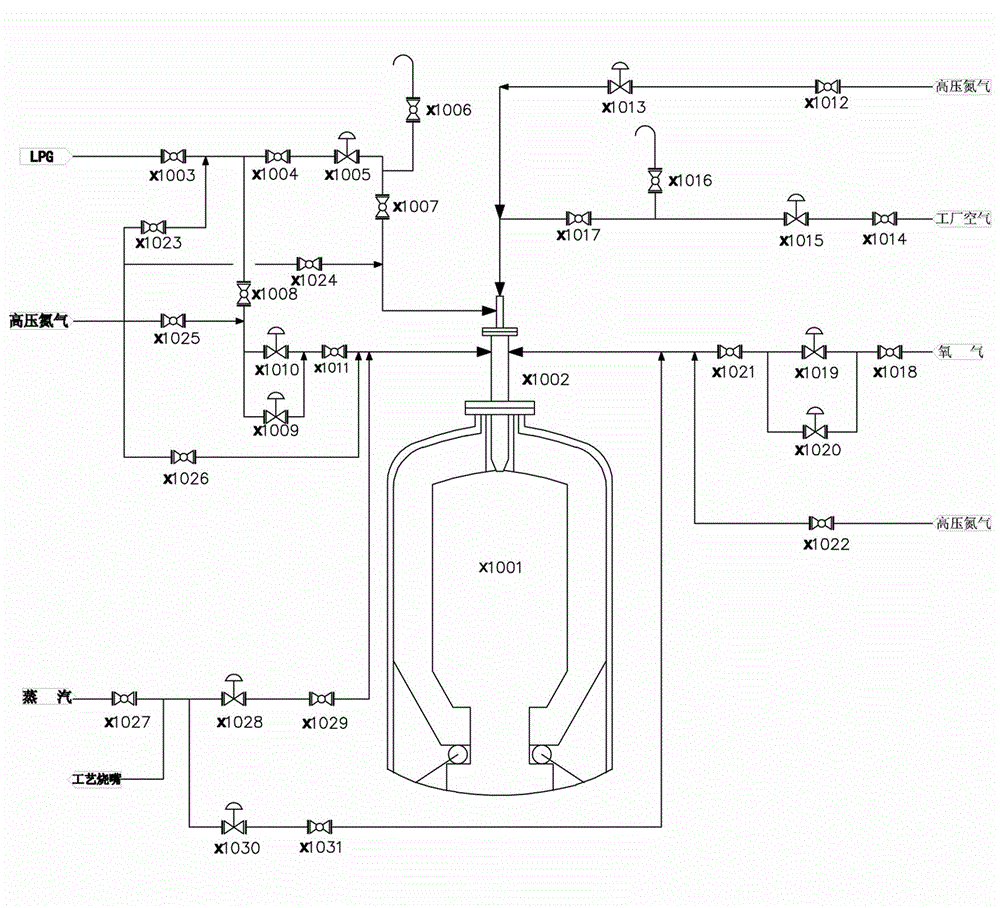

[0024] A pulverized coal pressurized gasifier ignition burner control system specific implementation is as follows:

[0025] 1. "Initialization" of the ignition burner: Confirm that the pressure of the syngas scrubber is <0.6Mpa, press the "Initialization" button of the ignition burner on the ESD interface, and confirm that the igniter protection nitrogen shut-off valve X1012 is closed.

[0026] 2. "Reset" of the ignition burner: Confirm that the fuel gas pressure is > 2.0Mpa, and press the "Reset" button of the ignition burner to reset the system.

[0027] (1) Nitrogen purge: confirm that the third high-pressure nitrogen shut-off valve X1024 is opened, and purge the ignition fuel gas into the furnace pipeline; confirm that the fifth high-pressure nitrogen shut-off valve X1026 is opened, and purge the heating fuel gas into the furnace pipeline; confirm that the first high-pressure nitrogen gas The cut-off valve X1022 is opened to purge the heating oxygen into the furnace pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com