Ignition device and ignition method for sinter pot test

An ignition device and technology for testing, applied in the direction of combustion ignition, combustion method, incandescent ignition, etc., can solve the problems that affect the ignition effect and the uniformity of combustion, separate combustion-supporting blower settings, poor operation synchronization, etc., to improve the fuel combustion effect , saving manpower and space, high ignition success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

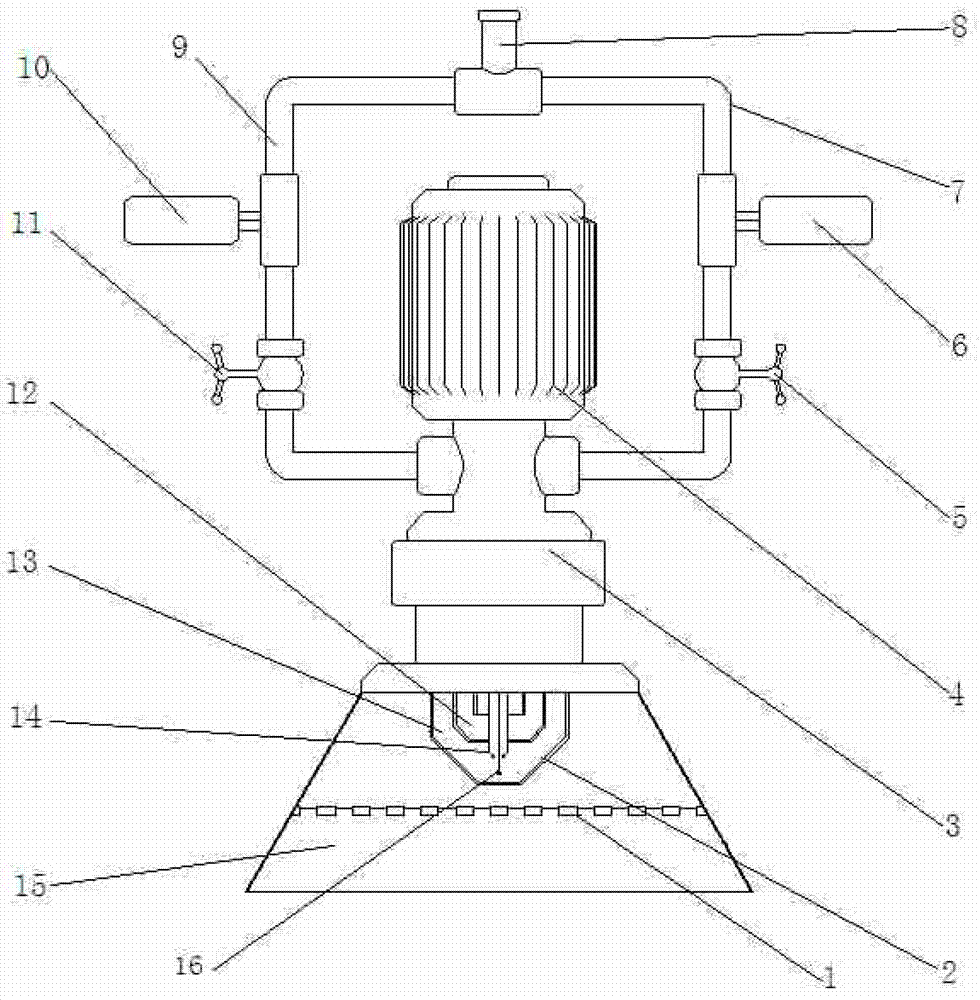

[0019] It can be seen from the accompanying drawings that the ignition device for the sintering cup test of the present invention consists of a flame distribution plate 1, a premixing chamber 2, a connecting seat 3, a blower 4, a main gas valve 5, a main solenoid valve 6, a main gas pipe 7, and a gas main pipe. 8. The auxiliary gas pipe 9, the auxiliary solenoid valve 10, the auxiliary gas valve 11, the gas outlet 12, the electronic igniter 14, the protective cover 15, the flame detection head 16 and the computer. The lower end of the blower 4 is provided with a combustion-supporting air pipe, and the protective cover 15 is fixed below the blower 4 by the connection seat 3, and the bottom of the connection seat 3, namely the protective cover 15, is provided with a premix chamber 2. The upper ends of the main gas pipe 7 and the auxiliary gas pipe 9 are respectively connected to the gas main pipe 8, and the main gas pipe 7 and the auxiliary gas pipe 9 are arranged on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com