Combined type coal water slurry nozzle provided with ignition device

An ignition device, coal-water slurry technology, applied in the direction of burners, lighting and heating equipment, granular/powdered fuel gasification, etc., can solve the problems of complex propulsion device structure, prolonging the heating furnace temperature time, complex ignition and heating process, etc. , to achieve the effects of improving the characteristics of not being easily combusted, simplifying complexity, and improving flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

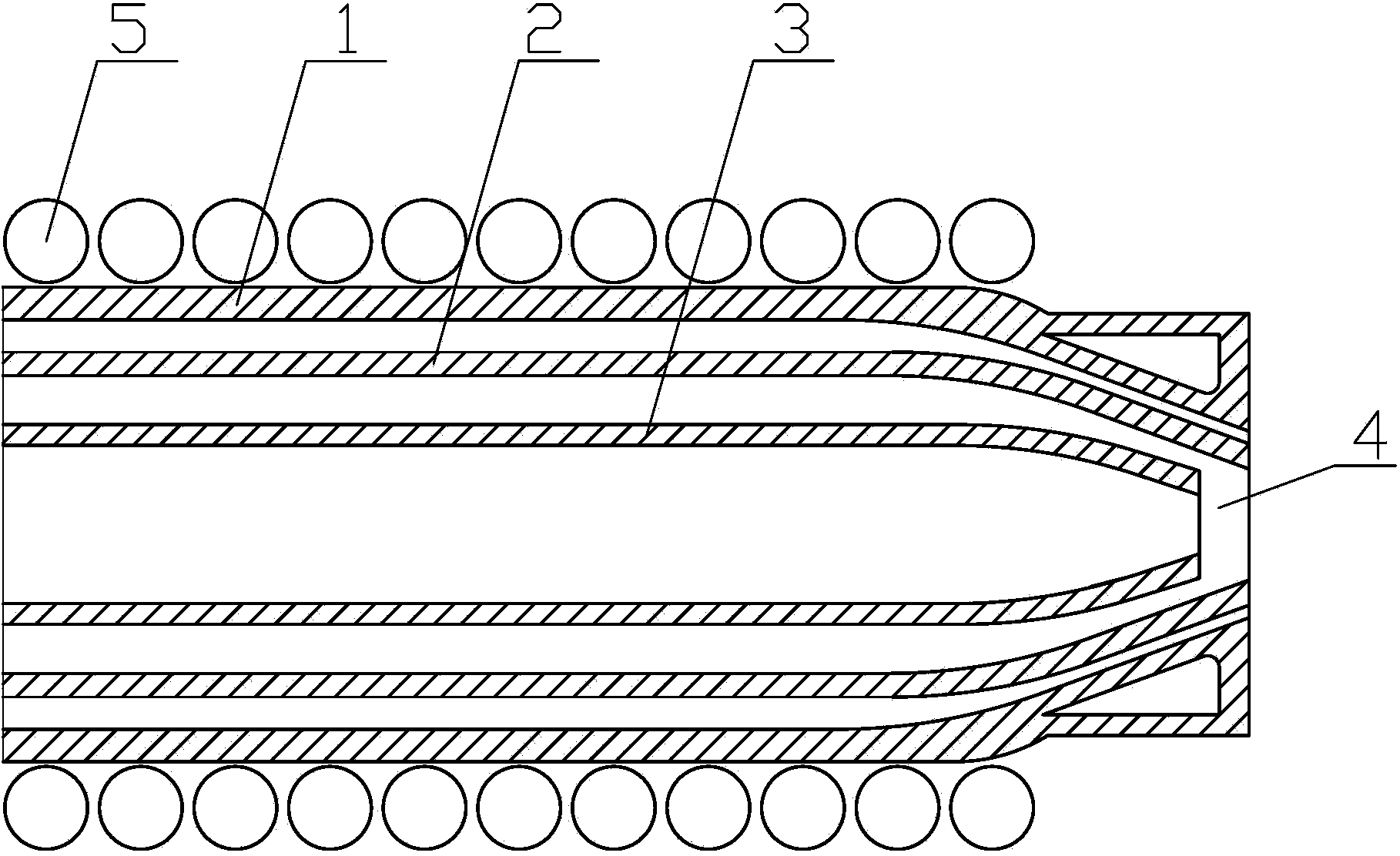

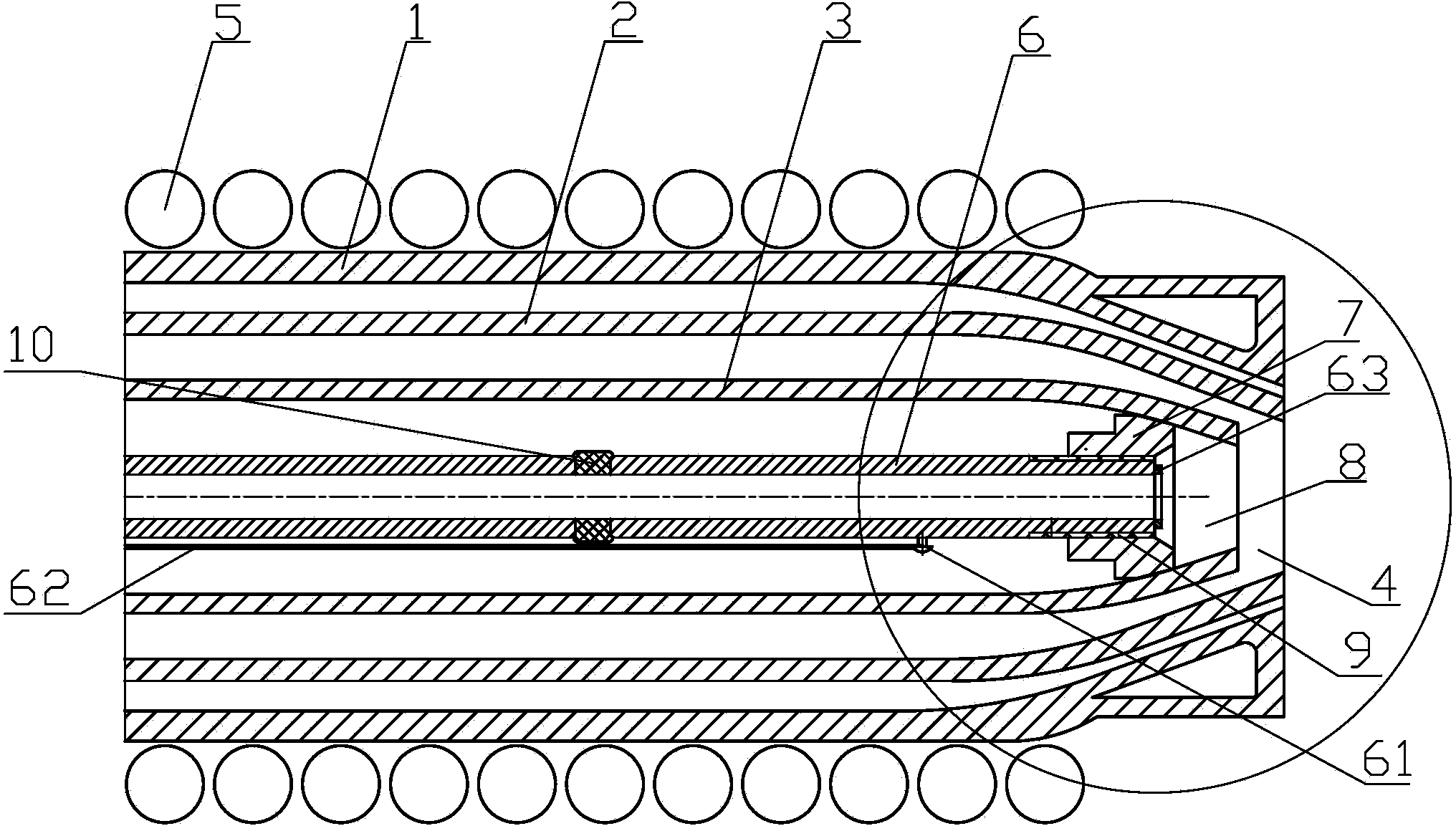

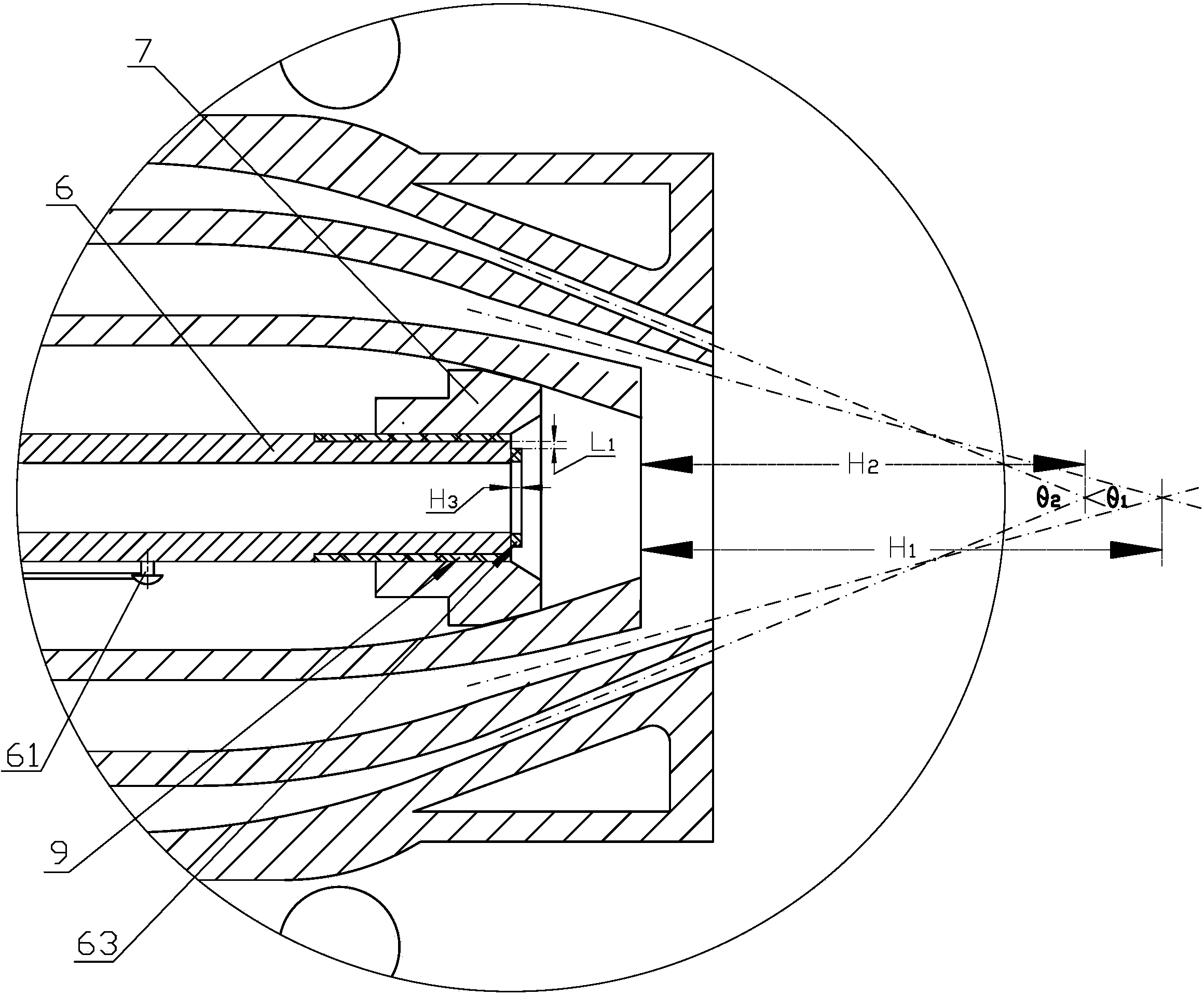

[0024] Such as figure 2 , image 3 As shown, a combined coal-water slurry burner with an ignition device includes an outer nozzle 1 for oxygen circulation, and a middle nozzle 2 for supplying coal-water slurry in the outer nozzle 1, which is arranged in the middle nozzle 2, the inner spray head 3 for oxygen flow, and the center pipe 6 made of metal material for the fuel gas flow in the inner spray head 3 . In order to ensure the service life, at least the inner wall of the front end of the middle nozzle 2 and the outer wall of the front end of the inner nozzle 3 are provided with cobalt alloy or wear-resistant materials to enhance the erosion resistance of the coal-water slurry.

[0025]The central pipe 6 is divided into front and rear sections, and the front and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com