Method for separating lithium and graphite from negative electrode material of waste lithium battery and resource utilization

A negative electrode material, lithium battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve environmental pollution and other problems, and achieve the effect of reducing environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Select the waste lithium-ion battery, discharge it, remove the shell and get the negative electrode copper foil, after it is dried, peel off the copper foil to get the graphite powder material, and put it into a muffle furnace at 600°C Burn for 1h.

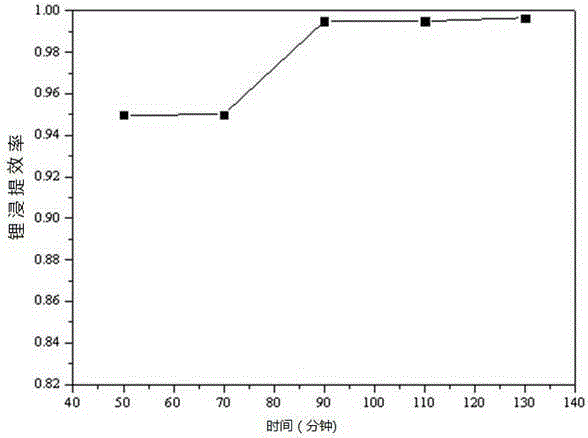

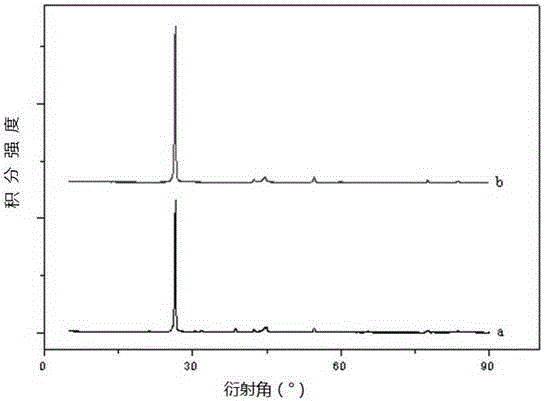

[0021] 2. Weigh 0.1g of waste electrode graphite powder and place it in a beaker, and conduct lithium leaching experiment in a low temperature and constant temperature reactor. The concentration of hydrochloric acid is controlled at 3mol / L, the solid-liquid ratio is maintained at 1:50g / mL, and the reaction time is 90min~130min , the reaction temperature is 80°C, and the volume ratio of hydrochloric acid / hydrogen peroxide is 10:1. After continuous stirring, the mixed solution is vacuum-filtered through a microporous filter membrane, and the filter membrane is washed with deionized water to separate lithium-containing solution and graphite material. Finally, the obtained graphite material is dried for future use.

[0022...

Embodiment 2

[0030] 1. Select the waste lithium-ion battery, discharge it, remove the shell and get the negative electrode copper foil, after it is dried, peel off the copper foil to get the graphite powder material, and put it into a muffle furnace at 600°C Burn for 1h.

[0031] 2. Weigh 0.1g of waste graphite electrode powder and place it in a beaker, and conduct lithium leaching experiment in a low-temperature constant temperature reactor. The concentration of citric acid is controlled at 0.15mol / L, and the solid-liquid ratio is maintained at 1:50g / mL. React for 40 minutes, and the temperature Set to 80°C, citric acid-hydrogen peroxide volume ratio 15:1. After continuous stirring, the mixed solution is vacuum-filtered through a microporous filter membrane, and the filter membrane is washed with deionized water to separate lithium-containing solution and graphite material. Finally, the obtained graphite material is dried for future use.

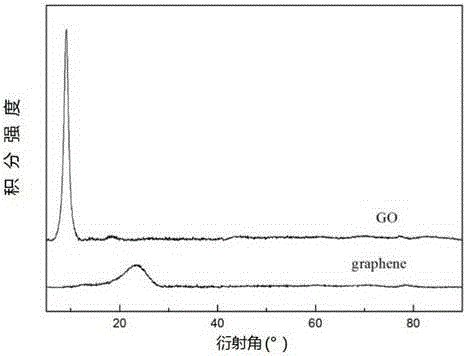

[0032] 3. Weigh 1g of graphite material into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com