Preparation of binderless ZSM-11 zeolite

A ZSM-11, binder-free technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of reduced effective surface area, easy deactivation and aggregation, and small zeolite size and other problems, to achieve the effect of accelerating the transformation speed, avoiding the nucleation growth period, and reducing the grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0014] Use tetrabutylammonium hydroxide (TBAOH) solution, tetraethylorthosilicate (TEOS) and water according to (TBA) 2 O: 6.22TEOS: 163H 2 The molar ratio of O was mixed and stirred evenly, aged and refluxed at 95° C. for three days to obtain the ZSM-11 seed crystal directing agent.

[0015] Take by weighing 200 grams of white carbon black, 12.5 grams of scallop powder, 36 grams of silicon-containing alumina powder (containing SiO 2 The mass percentage is 26%) and 51 grams of ZSM-11 seed crystal directing agent, adding an aqueous solution containing 20 grams of NaOH, and then adding 475 grams of silica sol (40% by weight) for kneading and drying to obtain a cylindrical precursor.

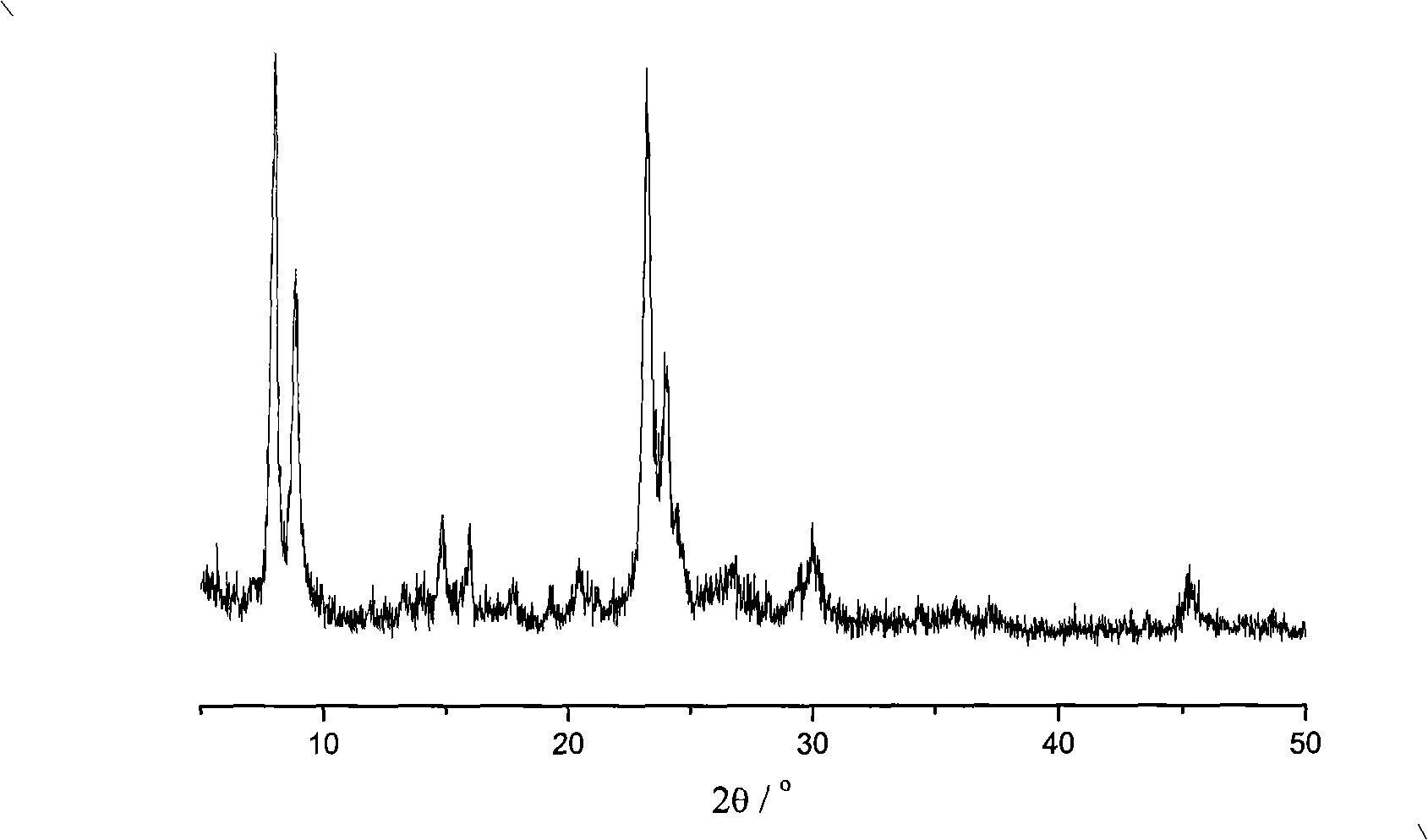

[0016] 40 grams of the cylindrical precursor prepared above and 80 grams of tetrabutylammonium hydroxide (TBAOH) solution with a concentration of 8% by mass were mixed and placed in a crystallization kettle at 160°C for hydrothermal treatment for 3 days, 5 days and 7 days. The product was washed...

Embodiment 4~6

[0018] Take by weighing 100 grams of diatomaceous earth and 140 grams of white carbon black, add 7.5 grams of field turnip powder, 36 grams of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O] and 60 grams of the seed directing agent prepared in [Example 1-3], and then add 300 grams of silica sol (40% by weight) to knead into a cylindrical shape and dry.

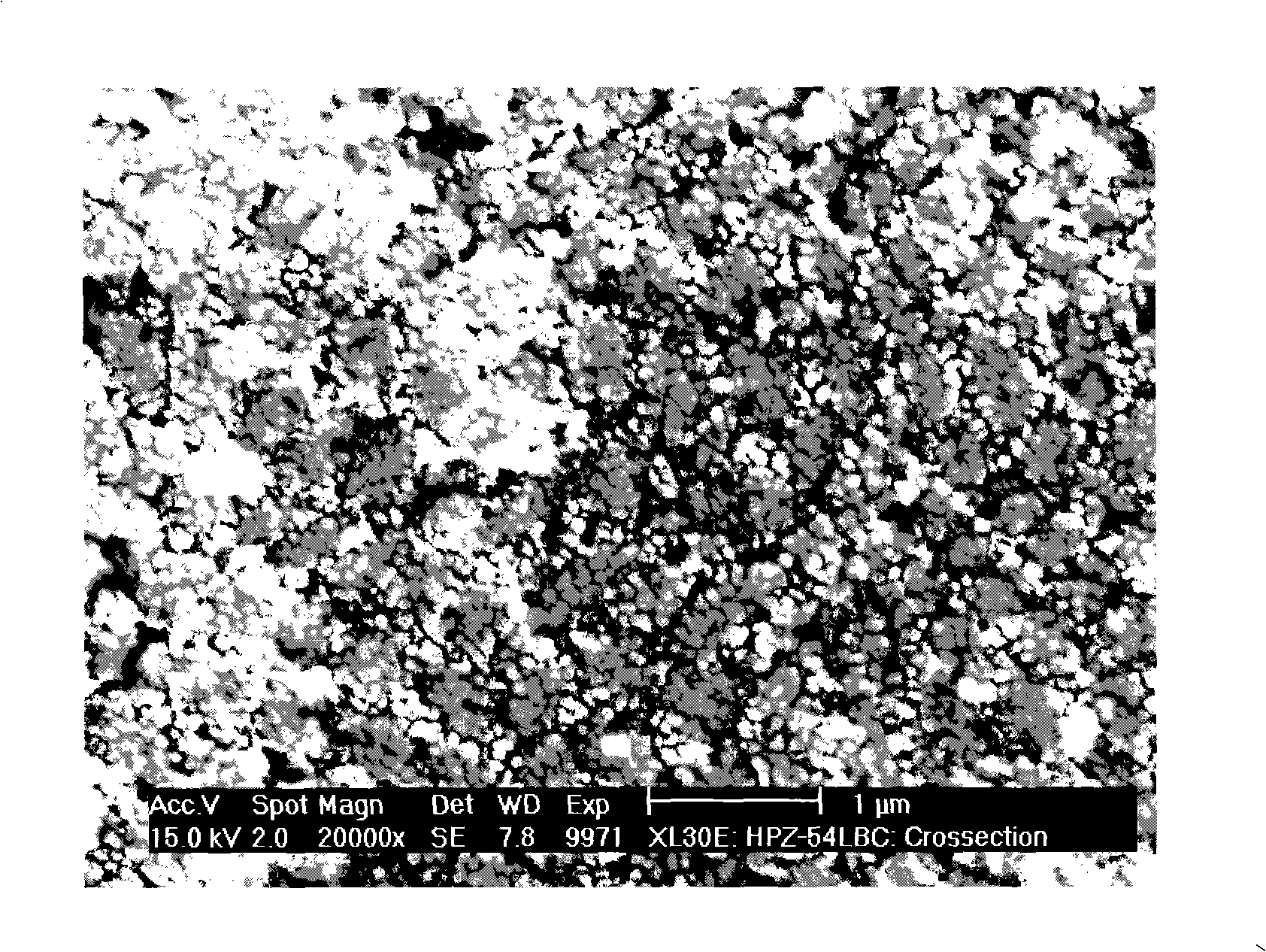

[0019] 40 grams of the above-prepared cylindrical precursor and 80 grams of 10% tetrabutylammonium hydroxide (TBAOH) solution were mixed and placed in a crystallization kettle at 140° C. for 5 days, 8 days and 10 days. The product was washed and dried with distilled water and then calcined at 550°C in an air atmosphere. The XRD patterns of the products all show that the crystalline phase is ZSM-11 zeolite, and the baseline is straight, indicating that no amorphous substance is contained. The SEM photos of the product show that the particle size of the ZSM-11 zeolite is less than 100 nanometers.

Embodiment 7~10

[0021] Use tetrabutylammonium hydroxide (TBAOH) solution, tetrabutylammonium bromide (TBABr), tetraethylorthosilicate (TEOS) and water according to 2TBAOH: TBABr: 15TEOS: 450H 2 The molar ratio of O was mixed and stirred uniformly, aged and refluxed at 100° C. for four days to obtain the ZSM-11 seed crystal directing agent.

[0022] Take by weighing 250 grams of white carbon black, add 12 grams of scallop powder, 27.8 grams of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O], 10 grams of NaOH and 80 grams of seed directing agent, and then add 400 grams of silica sol (40% by weight) for kneading into a cylindrical shape for drying.

[0023] 40 grams of the cylindrical precursor prepared above and 80 grams of tetrabutylammonium hydroxide (TBAOH) solution with a concentration of 8% by mass were mixed and placed in a crystallization kettle at 180°C for hydrothermal treatment for 2 days, 4 days and 6 days. The product was washed and dried with distilled water and then calcined at 550...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com