Preparation method for high-toughness nodular cast iron

A tough ball and cast iron technology, which is applied in the field of preparation of high-strength ductile cast iron, can solve problems such as complicated procedures, and achieve the effects of fewer procedures, high efficiency, and reduced spotlight and smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

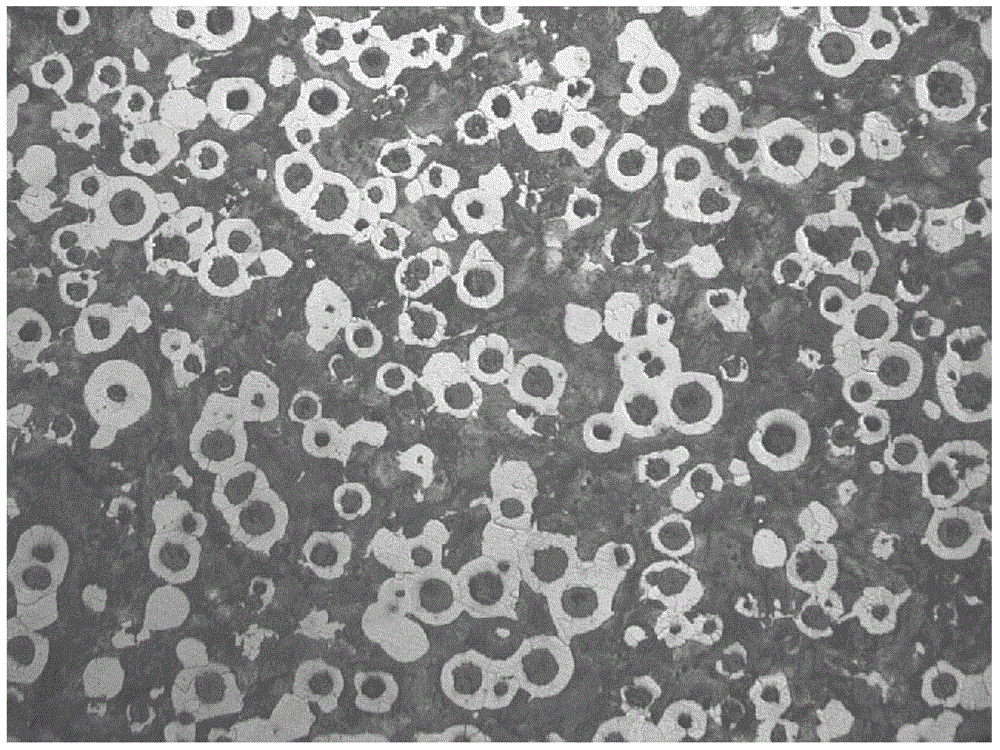

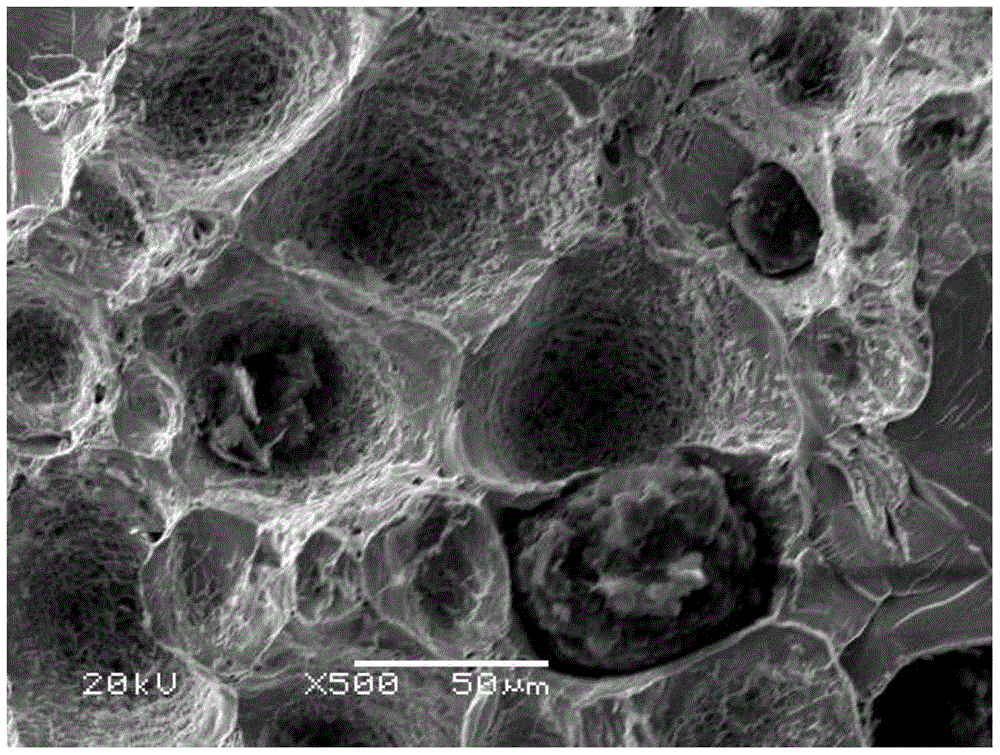

Image

Examples

Embodiment 1

[0031]Embodiment 1 (this embodiment adopts 3t intermediate frequency induction furnace to smelt molten iron)

[0032] A preparation method of high strength and toughness ductile iron, comprising the following steps:

[0033] The first step, chemical composition design, the material is based on mass percentage: C: 3.63%, Si: 2.59%, Mn: 0.42%, P≤0.05%, S≤0.02%, Mg: 0.041%, RE: 0.025%, Cu: 0.62%, the balance is Fe;

[0034] The second step, furnace material selection and intermediate frequency furnace smelting: use 3t intermediate frequency induction furnace to smelt molten iron, according to the mass percentage of pig iron: scrap steel: recycled material = 30%: 30%: 40% of the furnace material is added to the furnace for smelting, to ensure the raw material before treatment The chemical composition requirements of the molten iron, due to the use of cover-wrapped spheroidization treatment, the temperature of the molten iron drops less, and the temperature of the furnace is contr...

Embodiment 2

[0038] Embodiment 2 (this embodiment adopts 3t intermediate frequency induction furnace to smelt molten iron)

[0039] A preparation method of high strength and toughness ductile iron, comprising the following steps:

[0040] The first step, chemical composition design, the material is taken by mass percentage: C: 3.65%, Si: 2.58%, Mn: 0.31%, P≤0.04%, S≤0.02%, Mg: 0.046%, RE: 0.023%, Cu : 0.51%, the balance is Fe;

[0041] The second step, charge selection and intermediate frequency furnace smelting: use 3t intermediate frequency induction furnace to smelt molten iron, according to the mass percentage of pig iron: scrap steel: return charge = 60%: 10%: 30% charge is added to the furnace for smelting, to ensure the raw material before treatment The chemical composition of molten iron requires that the temperature of the molten iron be controlled at 1450-1480°C;

[0042] The third step, nodulizer selection and nodulizer treatment method: nodulizer is FeSiRE3Mg8 nodulizer, whic...

Embodiment 3

[0045] Embodiment 3 (this embodiment adopts 3t intermediate frequency induction furnace to smelt molten iron)

[0046] A preparation method of high strength and toughness ductile iron, comprising the following steps:

[0047] The first step, chemical composition design, materials are taken according to mass percentage: C: 3.72%, Si: 2.55%, Mn: 0.39%, P≤0.05%, S≤0.02%, Mg: 0.044%, RE: 0.034%, Cu : 0.50%, the balance is Fe;

[0048] The second step, furnace material selection and intermediate frequency furnace smelting: use 3t intermediate frequency induction furnace to smelt molten iron, and pig iron according to mass percentage: scrap steel: refurbishment material = 40%: 20%: 40% of furnace material is added to the furnace for smelting to ensure the raw material before treatment The chemical composition requirements of the molten iron, the temperature of the molten iron is 1450 ~ 1480 ℃;

[0049] The third step, the selection of nodulizer and nodulizer treatment method: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com