Method for preparing active carbon by using coal

A technology for preparing activated carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of large investment in electric tar collectors, difficult treatment of circulating wastewater, high energy and power consumption, and achieves broad application prospects, The effect of saving strategic materials and sufficient and stable supply of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

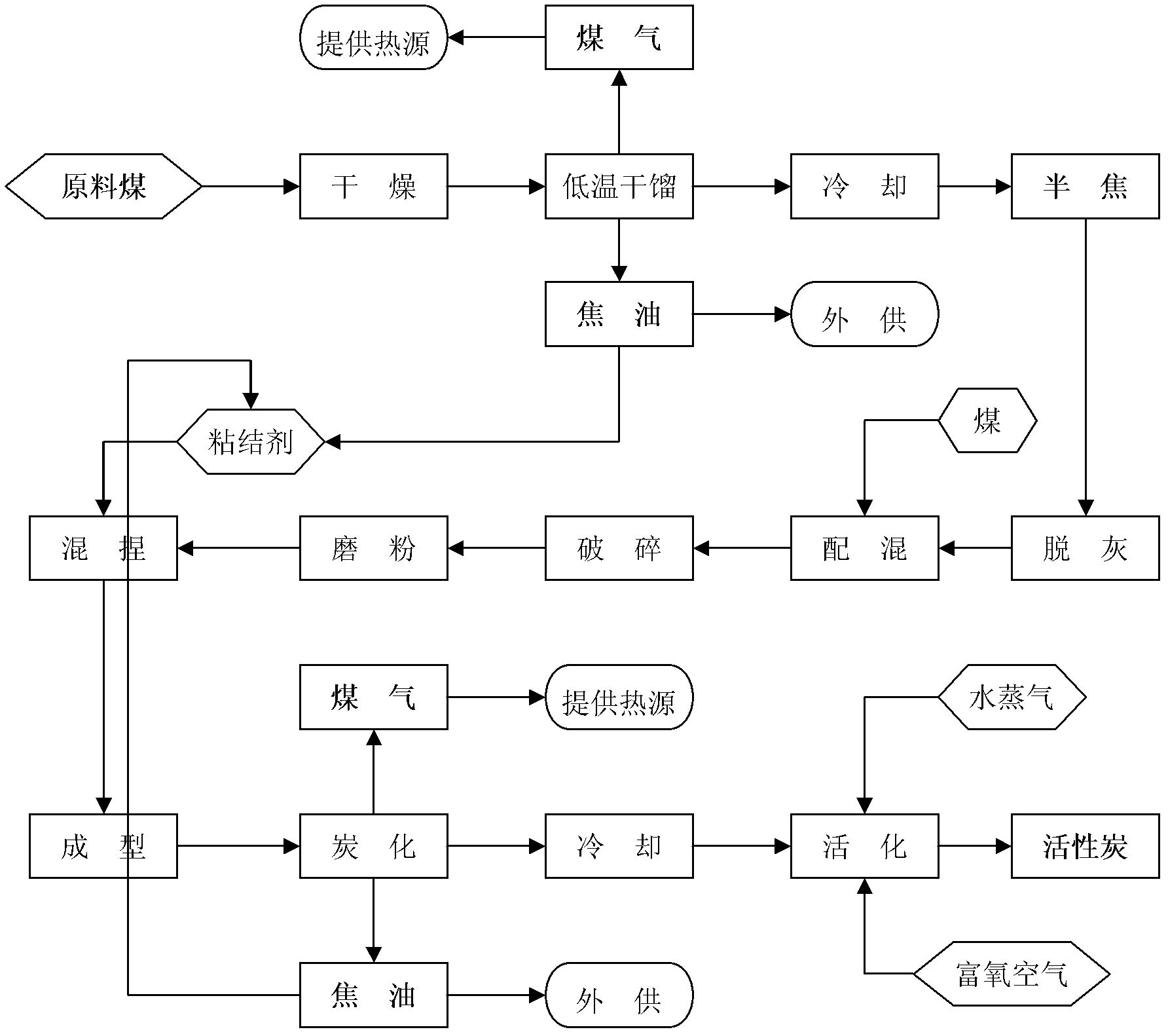

Method used

Image

Examples

Embodiment 1

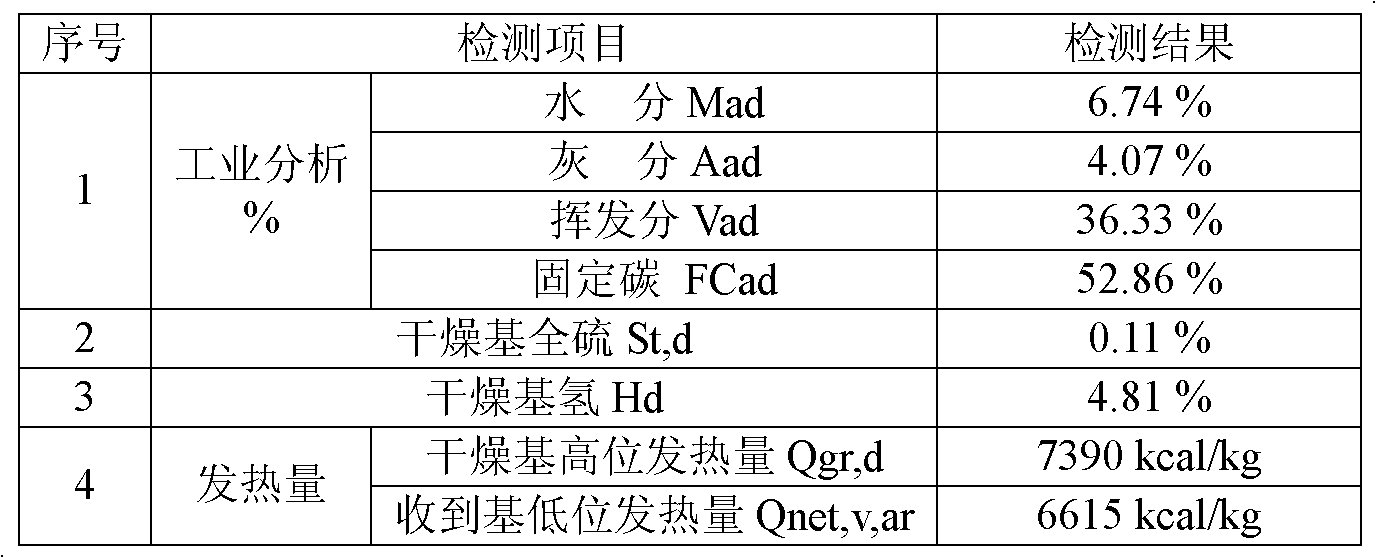

[0047] 1) Crushing and screening the raw long-flame coal to ≤30mm, the bulk density of the raw coal used is 680kg / m 3 , the industrial analysis results are as follows:

[0048]

[0049] 2) The raw material long-flame coal is measured by the belt scale from the raw material storage bin, and then sent to the rotary drying furnace at a speed of 4.2t / h through the double-turn valve. After starting, it is evenly sprinkled, and the raw material is in direct and full contact with the high-temperature exhaust gas of the gas generator during the spilling process, so that the temperature of the raw coal is preheated to 180°C, and the moisture in the coal and the gas adsorbed in the pores of the coal are removed. The rotation of the body continuously moves to the tail of the furnace, and finally the furnace body is discharged through the discharge box at the tail of the furnace. After drying, the moisture in the coal can be reduced to below 1%. The dust entrained in the dry tail gas ...

Embodiment 2

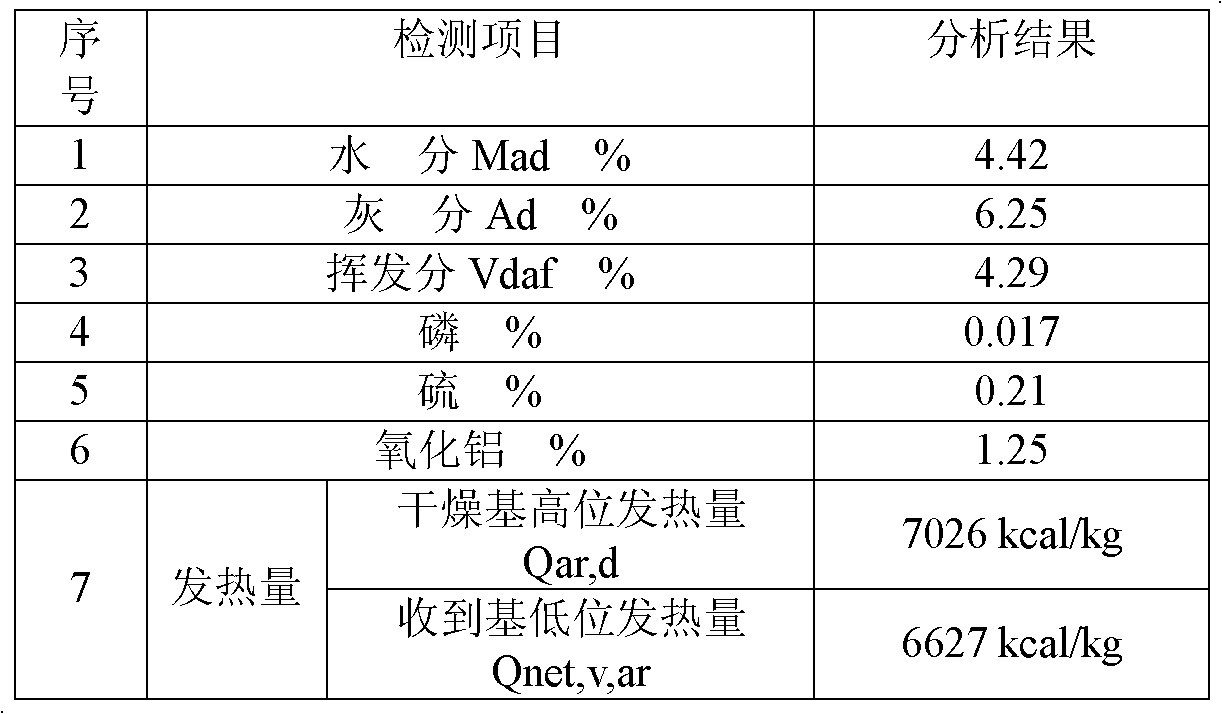

[0069] 1) Crushing and screening the raw coal to ≤30mm, the industrial analysis results are as follows:

[0070]

[0071] 2) After the raw coal is measured by the belt scale from the raw material storage bin, it is sent to the steam pipe rotary dryer at a speed of 2t / h through the double-reversed valve, so that the raw coal temperature is dried and desorbed for 30 minutes at 120°C. The moisture in the coal and the gas adsorbed in the pores of the coal are removed, and the moisture in the coal can be reduced to less than 10% after drying. The heat required for drying is transferred to the coal by the saturated water vapor through the steam tube of the drying furnace. The dust entrained in the dry tail gas is separated and collected by the first-stage cyclone separator and the first-stage bag filter.

[0072] 3) The dried coal enters the double-disc valve through the slide pipe, enters the rotary carbonization furnace through the double-disc valve, and heats and retorts the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| methylene blue value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com