High-boron low-alloy high-speed steel roll and preparation method thereof

A low-alloy, high-speed steel technology, applied in the direction of metal rolling, metal rolling, rolls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

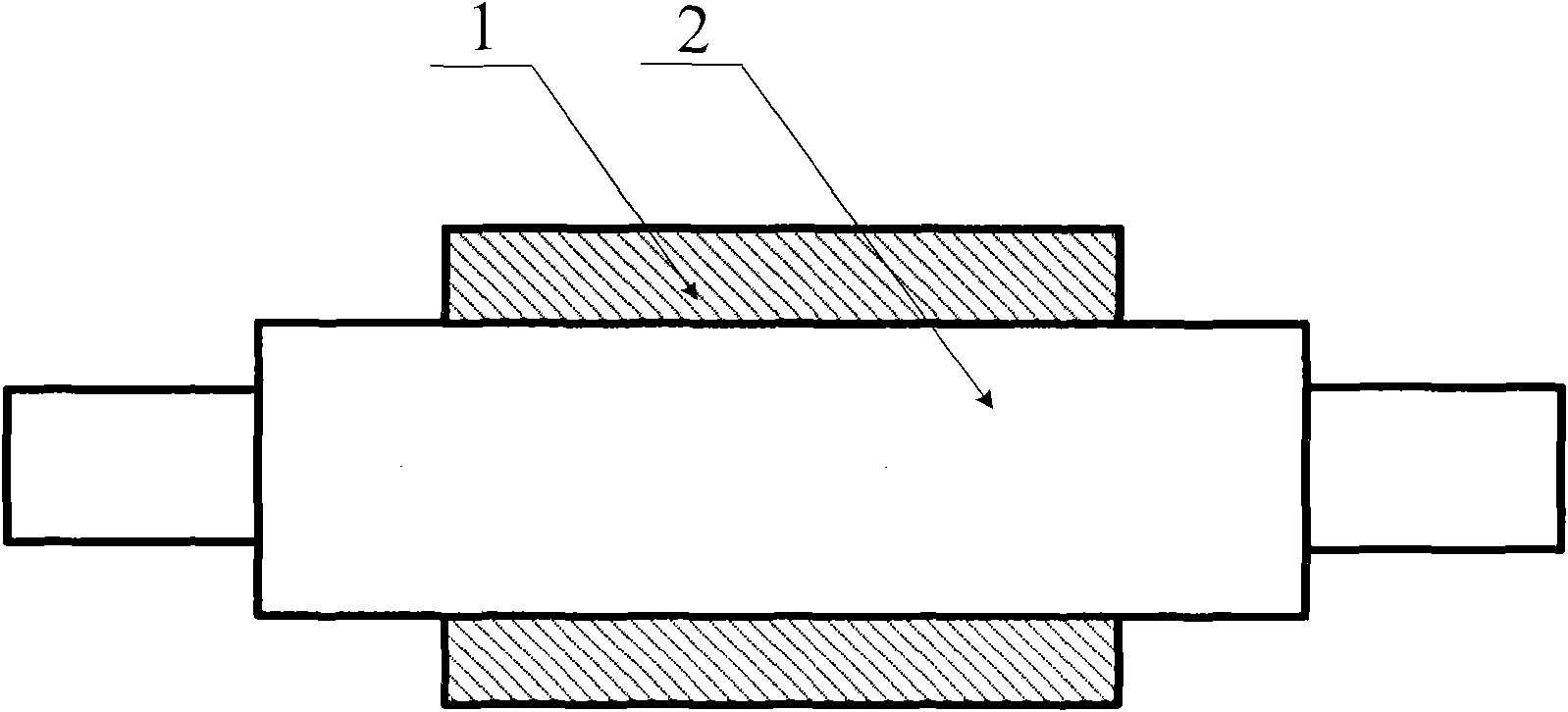

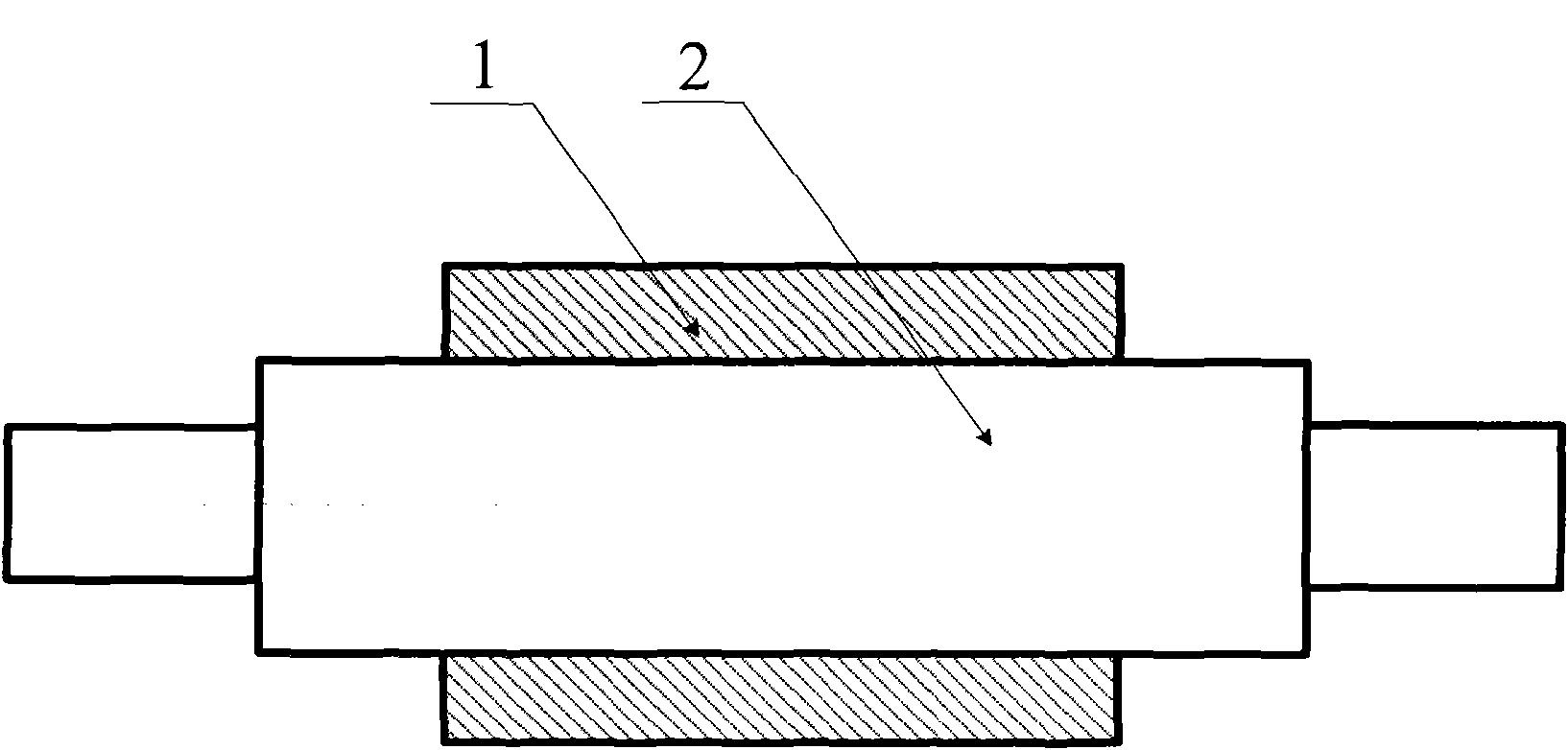

[0048] A 500 kg medium frequency induction furnace is used to melt the roll body 1, and a 1500 medium frequency induction furnace is used to melt the roll core 2. Its manufacturing process steps are:

[0049] ① First, common steel scrap, ferrochrome and ferrotungsten are mixed and heated and melted, and ferrosilicon and ferromanganese are added after molten steel is melted.

[0050] ② After adjusting the composition before the furnace, the temperature is raised to 1510°C, aluminum is added for deoxidation, and then ferroniobium, ferro-vanadium, ferro-boron and ferro-titanium are added in sequence, and the molten steel is released when the temperature rises to 1570°C.

[0051] ③Crush nitrogen-containing ferrochromium and yttrium-based rare earth magnesium alloys into small pieces with a particle size of 8-12mm, dry them at 150°C, place them at the bottom of the ladle, and perform compound modification treatment on molten steel by pouring into the ladle.

[0052] ④Centrifugal c...

Embodiment 2

[0060] The roll body 1 is smelted in a 500 kg intermediate frequency induction furnace, and the roll core 2 is processed from forged steel blanks. Its manufacturing process steps are:

[0061] ① First, common steel scrap, ferrochrome and ferrotungsten are mixed and heated and melted, and ferrosilicon and ferromanganese are added after molten steel is melted.

[0062] ② After adjusting the composition before the furnace, the temperature is raised to 1538°C, aluminum is added for deoxidation, and then ferroniobium, ferro-vanadium, ferro-boron and ferro-titanium are added in sequence, and the molten steel is released when the temperature rises to 1594°C.

[0063] ③Crush nitrogen-containing ferromanganese and yttrium-based rare earth-magnesium alloys into small pieces with a particle size of 8-12mm. After drying at 180°C, place them at the bottom of the ladle, and perform compound modification treatment on molten steel by pouring into the ladle.

Embodiment 3

[0072] A 1000 kg medium frequency induction furnace is used to melt the roll body 1, and a 3000 medium frequency induction furnace is used to melt the roll core 2. Its manufacturing process steps are:

[0073] ① First, common steel scrap, ferrochrome and ferrotungsten are mixed and heated and melted, and ferrosilicon and ferromanganese are added after molten steel is melted.

[0074] ② After adjusting the composition before the furnace, the temperature is raised to 1525°C, aluminum is added for deoxidation, and then ferroniobium, ferro-vanadium, ferro-boron and ferro-titanium are added in sequence, and the molten steel is released when the temperature rises to 1571°C.

[0075] ③Crush nitrogen-containing ferrochromium and yttrium-based rare earth magnesium alloys into small pieces with a particle size of 8-12mm, dry them at 170°C, place them at the bottom of the ladle, and use the method of pouring into the ladle to perform composite modification of molten steel.

[0076] ④The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com