Nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and melting method

A niobium vanadium microalloy and seismic steel technology, applied in the direction of manufacturing converters, etc., can solve the problems of unfavorable high-strength seismic steel production, promotion and application, waste of production cost of V resources, and occupation of enterprise profit space, etc. The effect of strong controllability, reduced alloying cost, good shock resistance and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

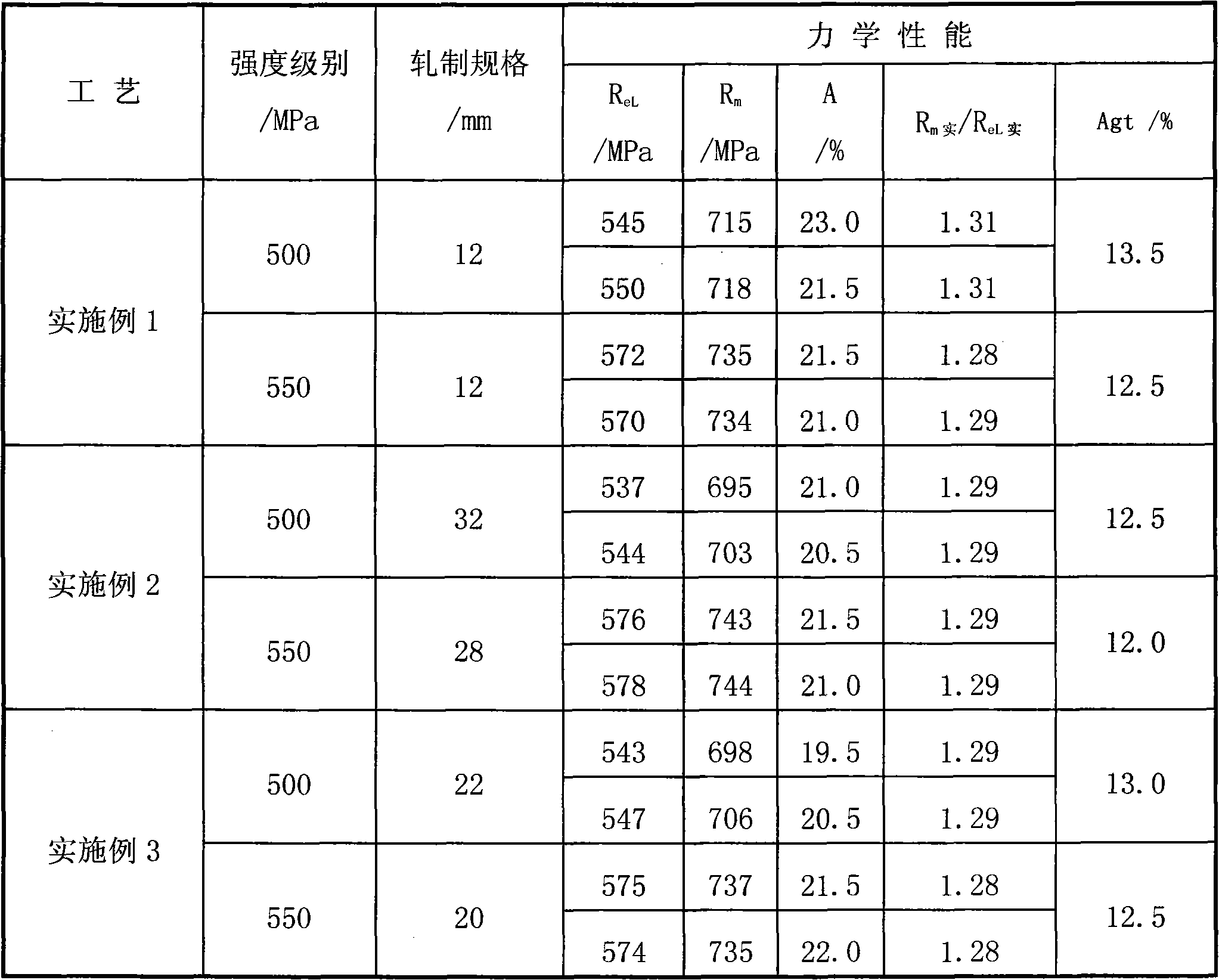

Examples

Embodiment 1

[0029] A. Add molten iron, steel scrap and pig iron with a temperature of 1275°C into a 50-ton LD oxygen converter as usual, and carry out top-bottom composite blowing. Slag, the amount of slag is controlled at 60kg / t 钢 , blowing by double slag method;

[0030] B. Smelting to the end point and control: the carbon content at the end point is 0.05%, the tapping temperature is 1670°C, the final slag (∑FeO%)≤22%, the slag blocking cone is used to tap the steel, and the ladle slag layer thickness is ≤45mm ;

[0031] C. Tapping under nitrogen blowing and stirring conditions, at the same time:

[0032] Press 0.60kg / t first 钢 The amount, Si content is 28.6wt%, and Ca content is 12.3wt%, and Ba content is that the composite deoxidizer of 9.4wt% is put into ladle bottom;

[0033] When tapping to 1 / 4, according to 18.9kg / t 钢 The amount, adding ferromanganese with a Mn content of 75.0wt%, and 7.8kg / t 钢 The amount of adding Si content is 72.0wt% ferrosilicon, and before tapping to 3 / ...

Embodiment 2

[0040] A. Add molten iron, steel scrap and pig iron with a temperature of 1285°C into a 50-ton LD oxygen converter according to the routine, and carry out top-bottom composite blowing. Slag, the amount of slag is controlled at 70kg / t 钢 , blowing by single slag method;

[0041]B. Smelting to the end point and control: the carbon content at the end point is 0.07%, the tapping temperature is 1685°C, the final slag (∑FeO%)≤25%, the slag blocking cone is used to tap the steel, and the thickness of the ladle slag layer is ≤50mm ;

[0042] C. Tapping under nitrogen blowing and stirring conditions, at the same time:

[0043] First press 0.85kg / t 钢 The amount that Si contains is 28.6wt%, and Ca content is 12.3wt%, and the composite deoxidizer that Ba content is 9.4wt% is dropped into ladle bottom;

[0044] When tapping to 1 / 3, according to 19.6kg / t 钢 The amount of adding ferromanganese with a Mn content of 77.5wt%, and 8.2kg / t 钢 The amount of adding Si content is 74.0wt% ferrosil...

Embodiment 3

[0051] A. Add molten iron, steel scrap and pig iron with a temperature of 1250°C into a 50-ton LD oxygen converter as usual for top-bottom compound blowing, and at the same time add active lime, light-burned dolomite, magnesite balls, and slag-removing agent as usual for manufacturing Slag, the amount of slag is controlled at 65kg / t 钢 , blowing by single slag method;

[0052] B. Smelting to the end point and control: the carbon content at the end point is 0.06%, the tapping temperature is 1700°C, the final slag (∑FeO%)≤25%, the slag blocking cone is used to tap the steel, and the thickness of the ladle slag layer is ≤50mm . ;

[0053] C. Deoxidation alloying:

[0054] First press 0.75kg / t 钢 The amount, Si content is 28.6wt%, and Ca content is 12.3wt%, and Ba content is that the composite deoxidizer of 9.4wt% is put into ladle bottom;

[0055] When tapping to 1 / 4, according to 19.1kg / t 钢 The amount, adding ferromanganese with a Mn content of 76.5wt%, and 8.0kg / t 钢 The am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com