Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

A technology of high-pressure leaching and laterite nickel ore, applied in the direction of improving process efficiency, etc., can solve the problems of large ore processing capacity, low recovery rate of nickel and cobalt, and insufficient recovery of valuable metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

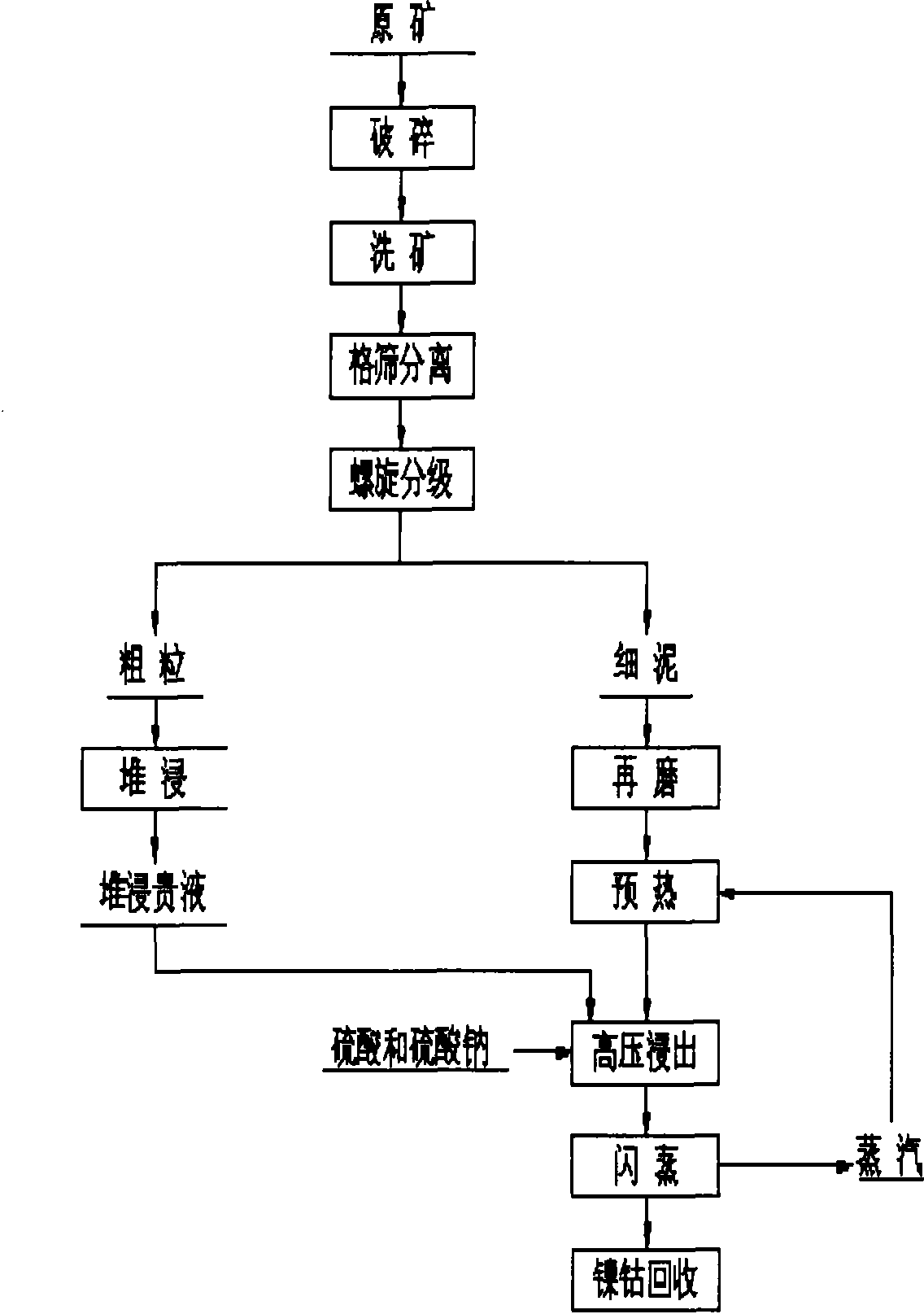

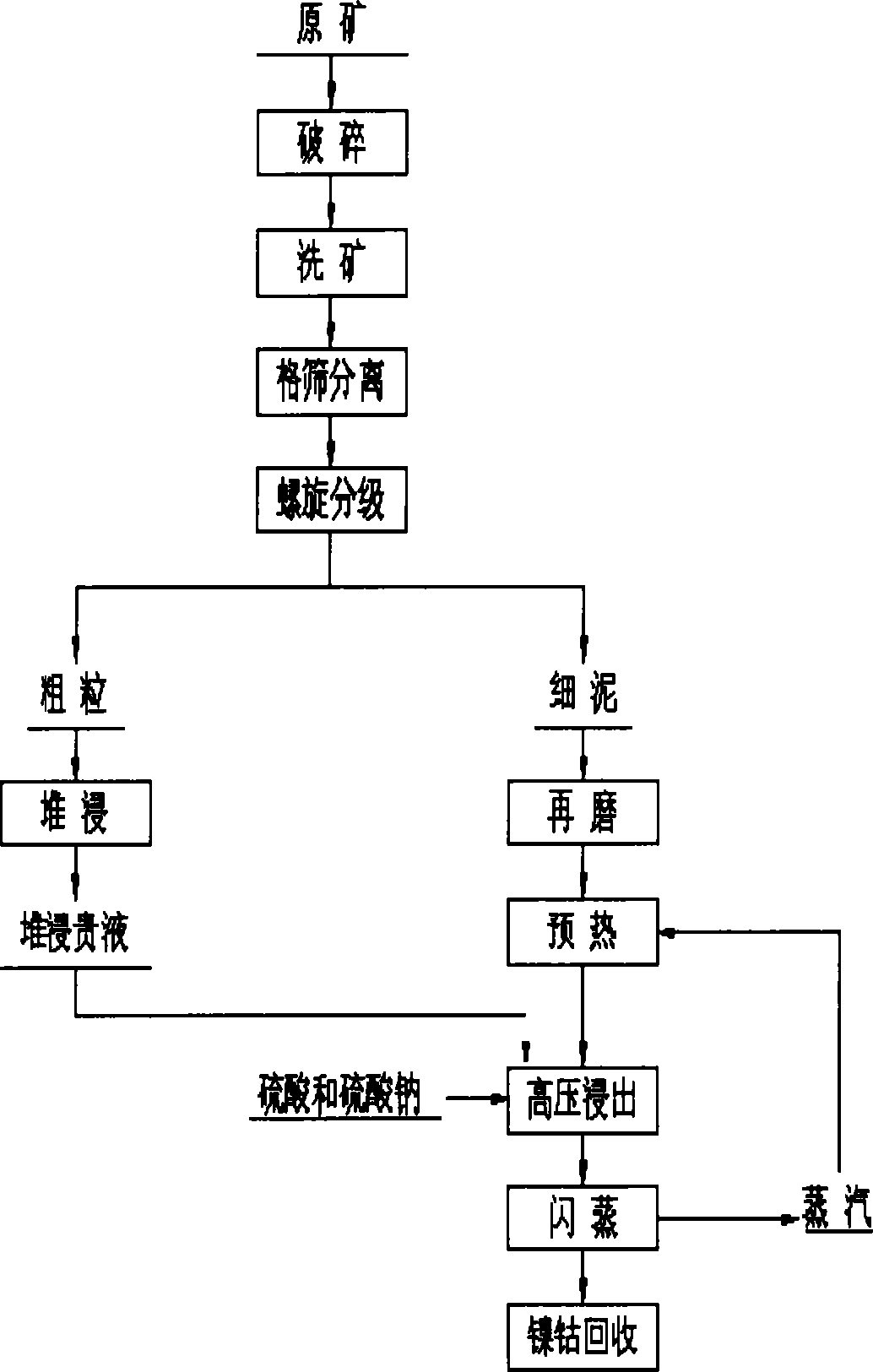

[0058] see figure 1, the ore is pre-screened first. The raw ore is transported by car from the stope to the raw ore warehouse of the ore washing workshop (or the raw ore storage yard is stockpiled, and then fed into the raw ore warehouse by the front loading machine), with a maximum block size of φ1000mm. The large pieces over 300mm are separated by the bar screen on the top of the original ore bin, and the material under the bar screen enters the ore washing operation, and the large pieces on the screen are removed or crushed by a mobile hydraulic rock crusher, and then transported by the ore truck Transport it back to the stope for backfill or as road construction stone.

[0059] Then wash, grind and concentrate. The material under the bar screen on the top of the raw ore bin enters the raw ore bin and then is fed into the cylinder washing machine through the iron plate feeder. After washing, the φ+20mm material is crushed to φ-20mm and all the φ-20mm ore Through the comb...

Embodiment 2

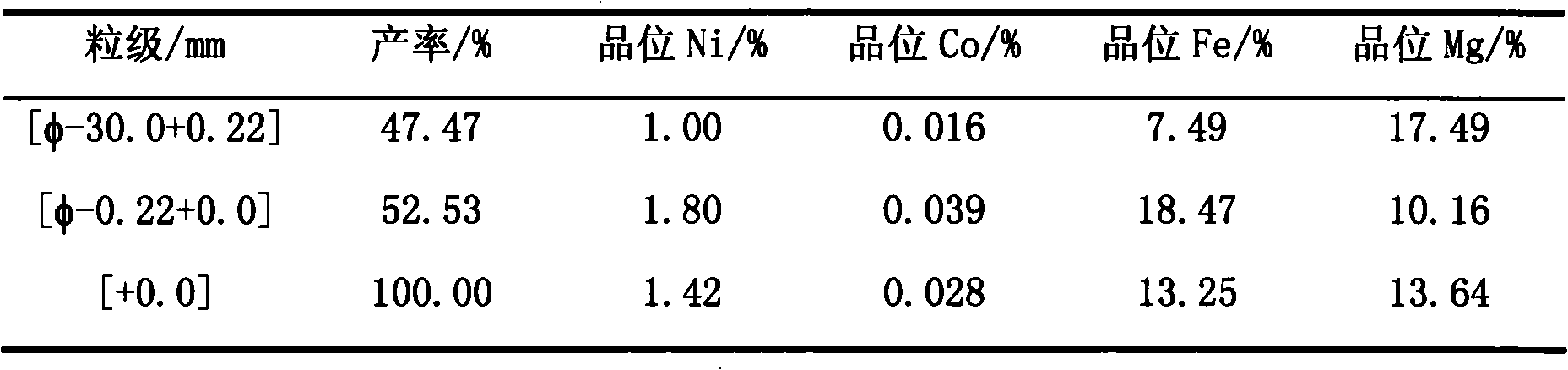

[0065] The ore used in Example 2 comes from the Moweitang laterite nickel deposit in Myanmar. After the ore is classified, the coarse-grained part of limonite and the fine-grained part of saprolite have the composition given in Table 1.

[0066] Table 1 Composition of the coarse-grained part of limonite and fine-grained part of saprolite after ore classification

[0067]

[0068] 268.35g of saprolite, 402.53ml of water and 463.30ml of coarse-grained ore heap leaching liquid were adjusted into a pulp and placed in an autoclave, and a certain amount of sulfuric acid was added to conduct a high-pressure acid leaching test. The fixed leaching conditions are as follows, the leaching temperature is 250°C, the leaching oxygen partial pressure is 0.6MPa, the leaching time is 1h, and the stirring intensity is 600rpm. The relationship between the amount of acid added and the leaching rate of nickel was investigated.

[0069] After the leaching is completed, filter the leached pulp w...

Embodiment 3

[0074] The ore used in Example 3 is the same as that in Example 2, all of which come from the Moweitang laterite nickel deposit in Myanmar. The coarse-grained part of limonite and the fine-grained part of saprolite after ore classification also have the composition given in Table 1.

[0075] 268.35g of saprolite, 402.53ml of water, 13g of sodium sulfate and 463.30ml of coarse ore heap leaching liquid were adjusted into a pulp and placed in an autoclave, and 43.8ml of sulfuric acid was added for high-pressure acid leaching test. The fixed leaching conditions are as follows, the sulfuric acid dosage is 300kg / t ore, the leaching temperature is 250°C, the leaching oxygen partial pressure is 0.6MPa, the leaching time is 1h, and the stirring intensity is 600rpm. Investigate the leaching rate of metals such as nickel and cobalt.

[0076] After the leaching is completed, filter the leached pulp with a suction filtration device, and perform 4-stage rinsing with 1000ml of heated acid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com