Environmentally-friendly amine cationic collector and using method thereof

A cationic collector, environment-friendly technology, applied in chemical instruments and methods, solid separation, preparation of aminohydroxy compounds, etc., to achieve the effect of strong practicability, strong collection ability and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

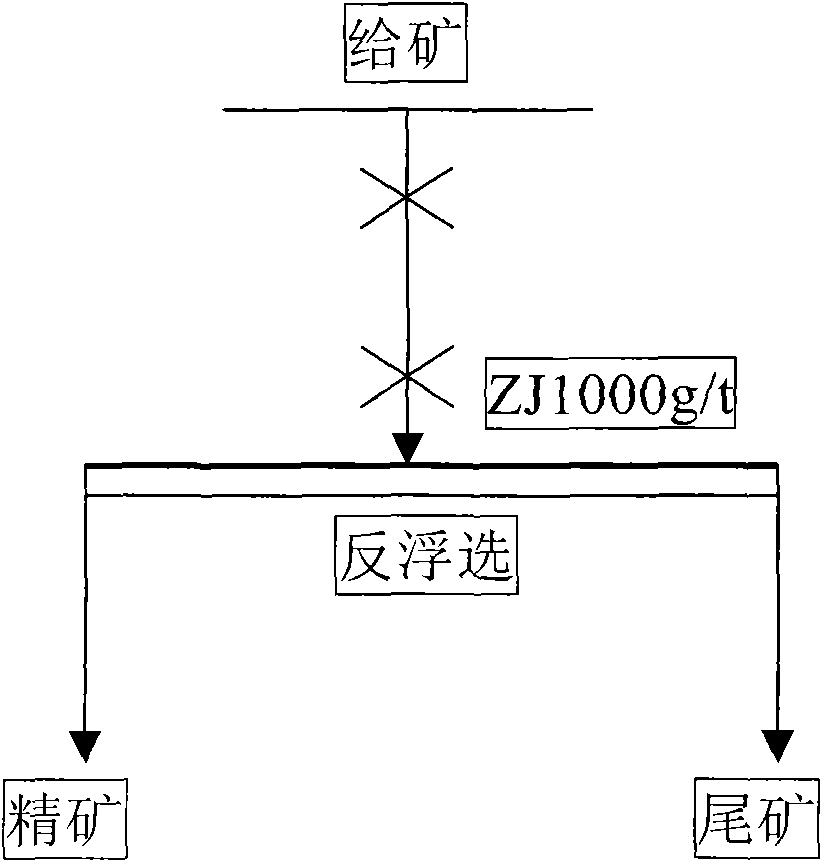

Embodiment 1

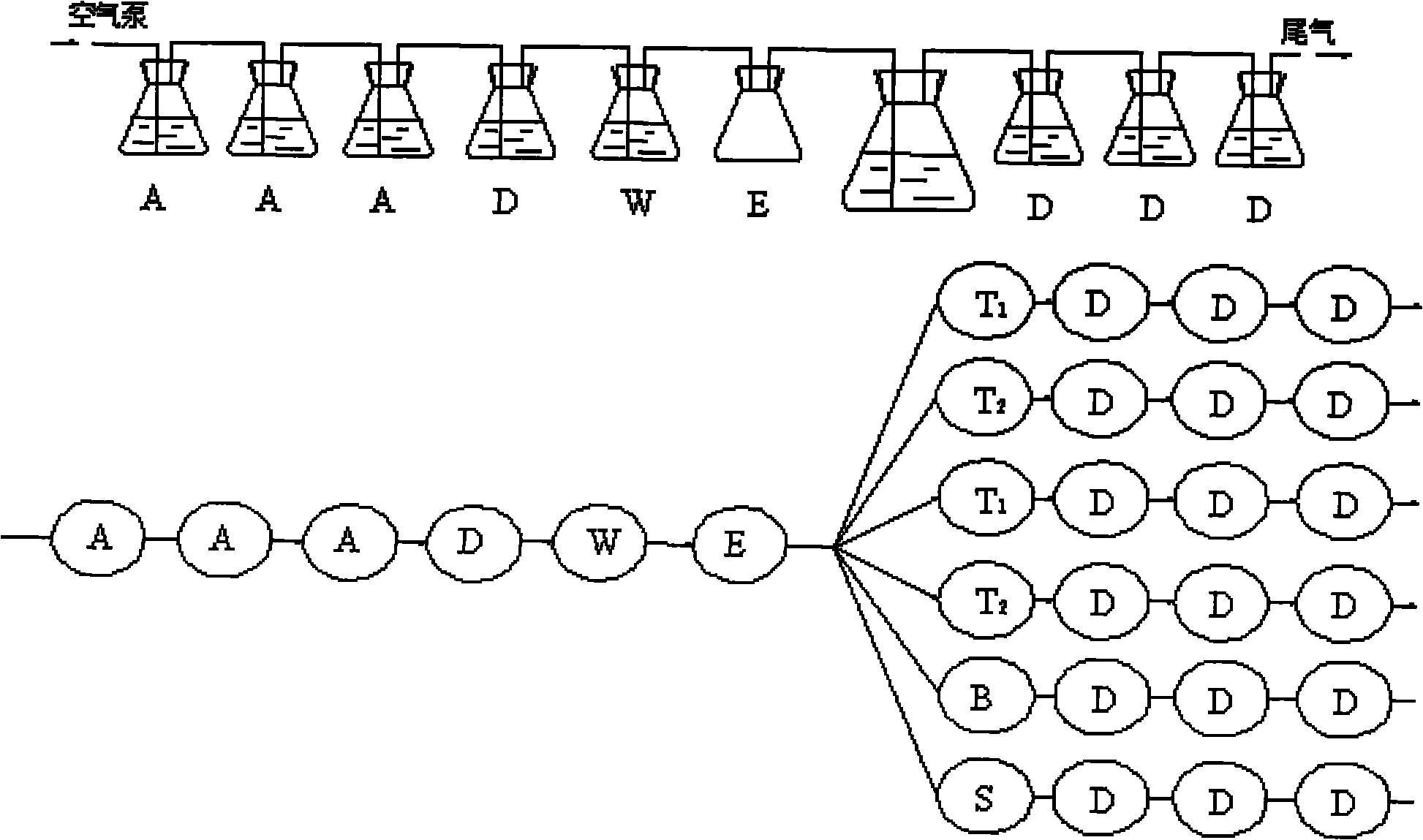

[0025] Take a certain amount of stearic acid and join in the three-necked flask of 250mL, under N 2 Under protection, rise to 80°C, after it is completely melted, add 0.5% hypophosphorous acid in proportion as a catalyst, then add triethanolamine, the molar ratio is stearic acid: triethanolamine=1:0.2, heat up to 170°C, and react for 6h , to obtain a light yellow transparent liquid. The temperature of the above reaction mixture was lowered to 60°C, and the introduction of N 2 , add a certain amount of organic solvent isopropanol, and slowly add ethyl chloride dropwise to carry out quaternization reaction according to the molar ratio of esterification product and ethyl chloride at a ratio of 1.0:0.99. No heating is required during the dropping process, because the The reaction is exothermic. After the dropwise addition was completed, it was heated to 80°C and reacted for 8 hours under reflux. Promptly obtain the amine cationic collector ZJ, which is used for reverse flotatio...

Embodiment 2

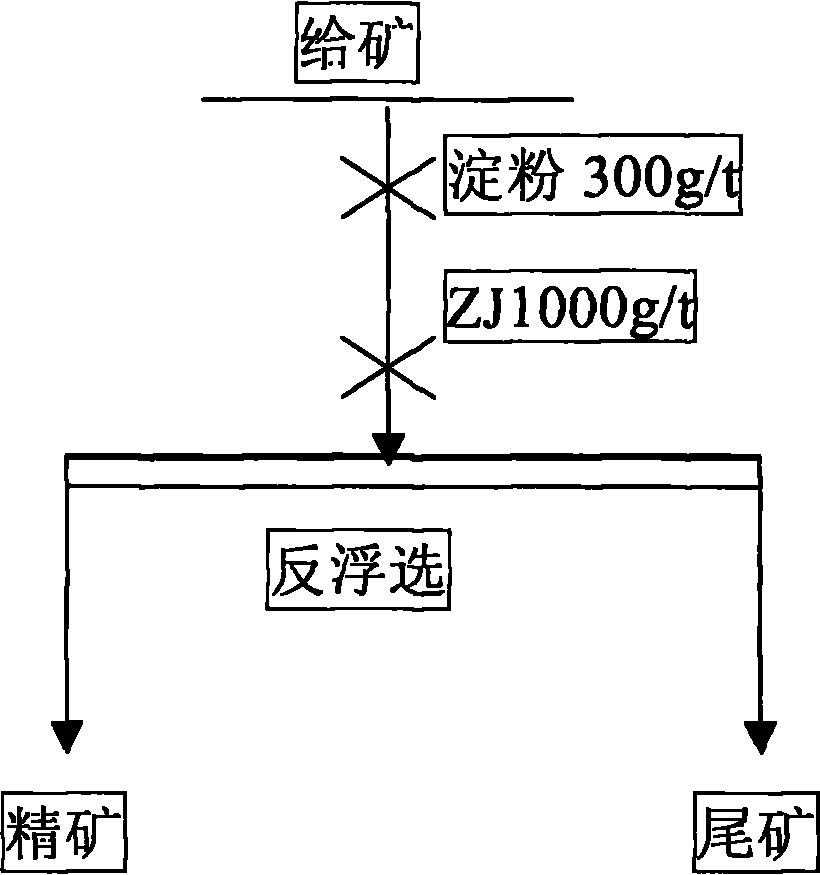

[0028] Take a certain amount of stearic acid and join in the three-necked flask of 250mL, under N 2 Under protection, rise to 80°C, after it is completely melted, add 0.5% hypophosphorous acid in proportion as a catalyst, then add triethanolamine, the molar ratio is stearic acid: triethanolamine=1:0.2, heat up to 170°C, and react for 6h , to obtain a light yellow transparent liquid. The temperature of the above reaction mixture was lowered to 60°C, and the introduction of N 2 , add a certain amount of organic solvent isopropanol, and slowly add ethyl chloride dropwise to carry out quaternization reaction according to the molar ratio of esterification product and ethyl chloride at a ratio of 1.0:0.99. No heating is required during the dropping process, because the The reaction is exothermic. After the dropwise addition was completed, it was heated to 80°C and reacted for 8 hours under reflux. Promptly obtain the amine cationic collector ZJ, which is used for reverse flotatio...

Embodiment 3

[0031] ZJ is a quaternary ammonium salt cationic surfactant containing an ester group, and its physical and chemical properties are as follows:

[0032] Appearance: white to light yellow powder;

[0033] Odor: No special irritating odor;

[0034] Solid content: ≥98%;

[0035] Free amine: ≥1%;

[0036] pH (5% isopropanol): 7±2;

[0037] Dissolve in water: Stir and dissolve evenly at 70-80°C.

[0038] The preparation method of ZJ is as follows: this process is carried out in two steps, the first step is esterification, adding fatty acid, triethanolamine, and catalyst into the reactor, slowly raising the temperature to 160-180°C, and reacting for 6h-8h. When there is no residual amine value in the product, it is the end of the reaction, and a light yellow transparent liquid is obtained, and the water generated by the reaction is taken out by nitrogen gas. The product after esterification is a mixture of mono-, di-, and tri-esters, with diesters as the main products. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com