Combined machining spindle unit of supersonic vibration assistant grinding-impulse discharge

A technology of ultrasonic vibration and pulse discharge, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in meeting various processing requirements, achieve good results, compact equipment structure, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

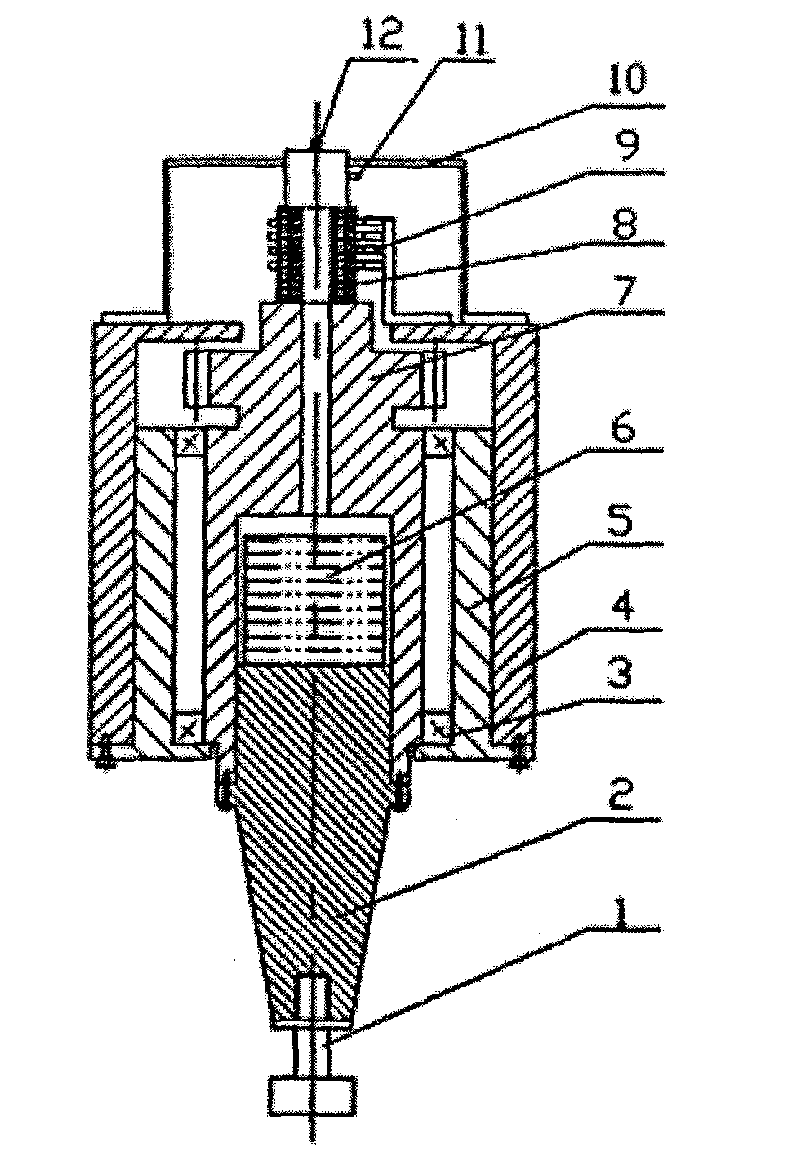

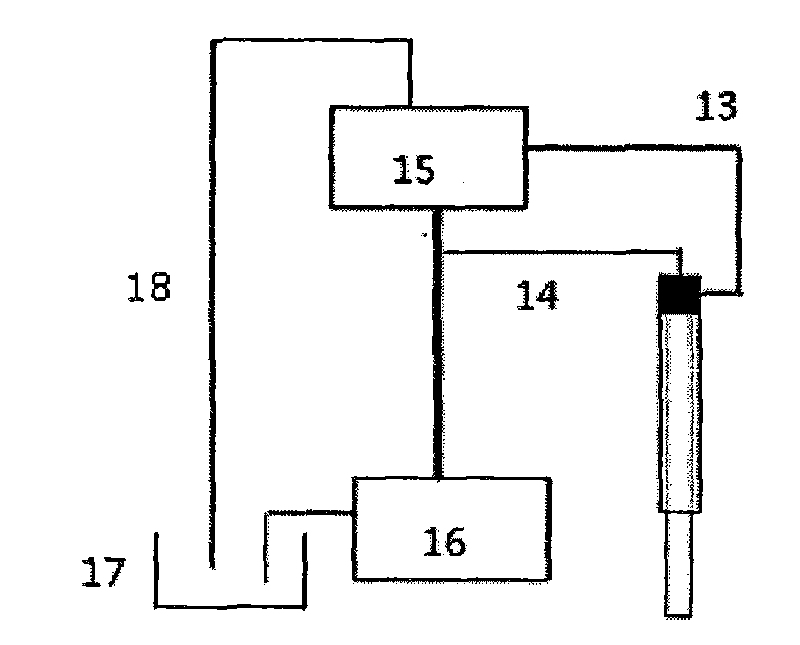

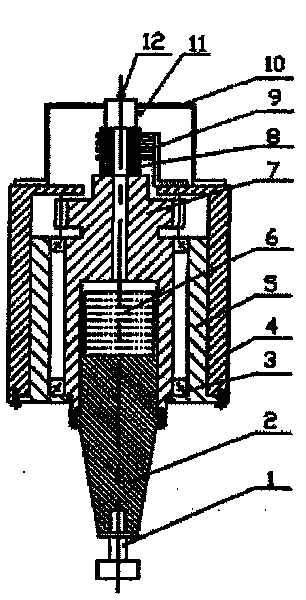

[0016] Such as figure 1 , figure 2 , it includes a housing 4, the main shaft passes through the housing 4 and is connected with an ultrasonic vibration processing device, an electric spark pulse discharge machining and a grinding processing device are provided on the ultrasonic vibration processing device, and a correction device is also provided on the inner wall of the housing 4 Support sleeve 5, tapered roller bearing 3 is installed in its inner side. The main shaft is also connected with the transmission pulley 7.

[0017] The ultrasonic vibration processing device includes an ultrasonic horn 2, a piezoelectric ceramic transducer plate 6 is installed on its upper end, an electric spark pulse discharge machining and grinding device is installed on the lower end, and a double rotatable collector ring 8 and carbon steel are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com