Performance analysis and fault simulation experiment system of wind machine

A fault simulation and experimental system technology, applied in the field of wind turbine experimental device, wind turbine performance analysis and fault experimental research experimental equipment field, can solve the research that restricts the operating performance and fault characteristics of wind turbines, restricts the optimal design of wind turbines, In-depth research on the theory of fault diagnosis of shafting dynamics characteristics, inability to obtain bearing vibration signals, etc., to achieve the effect of good openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

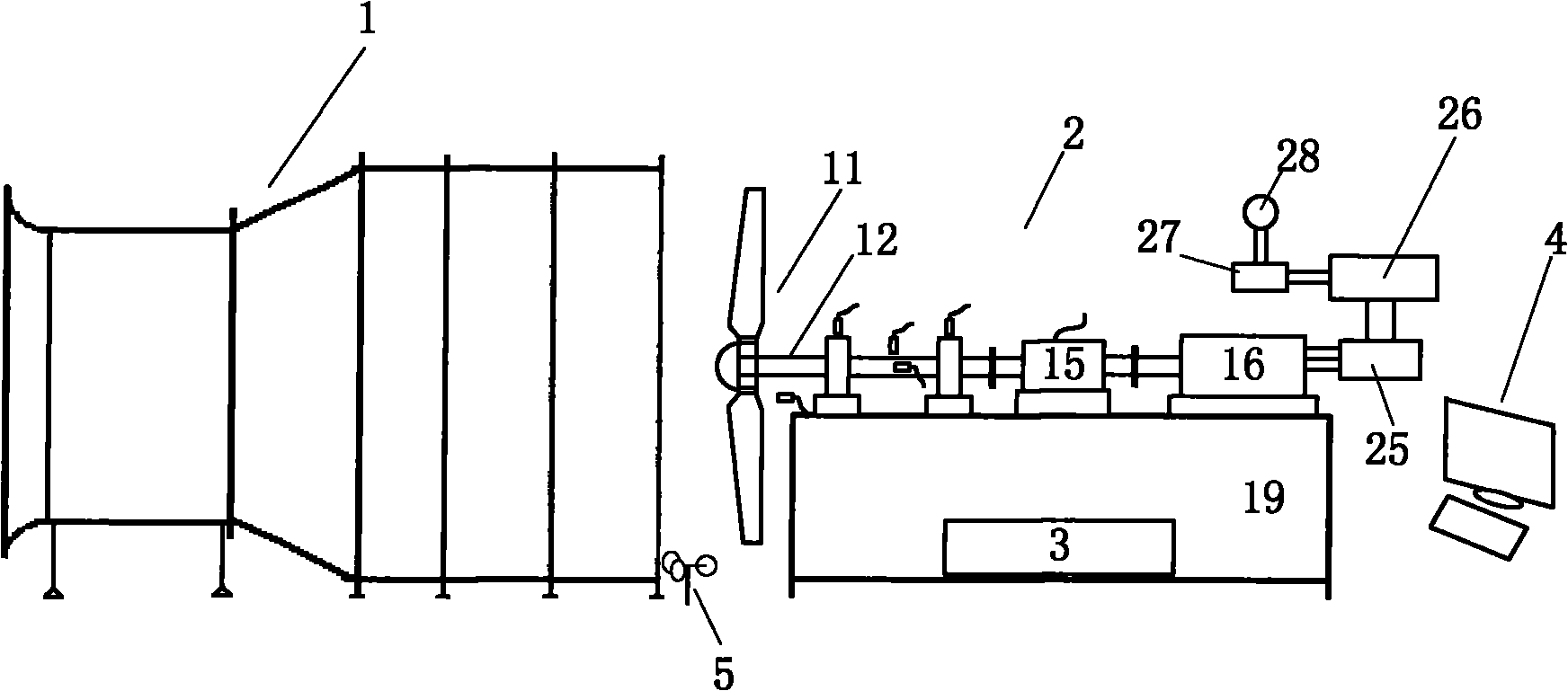

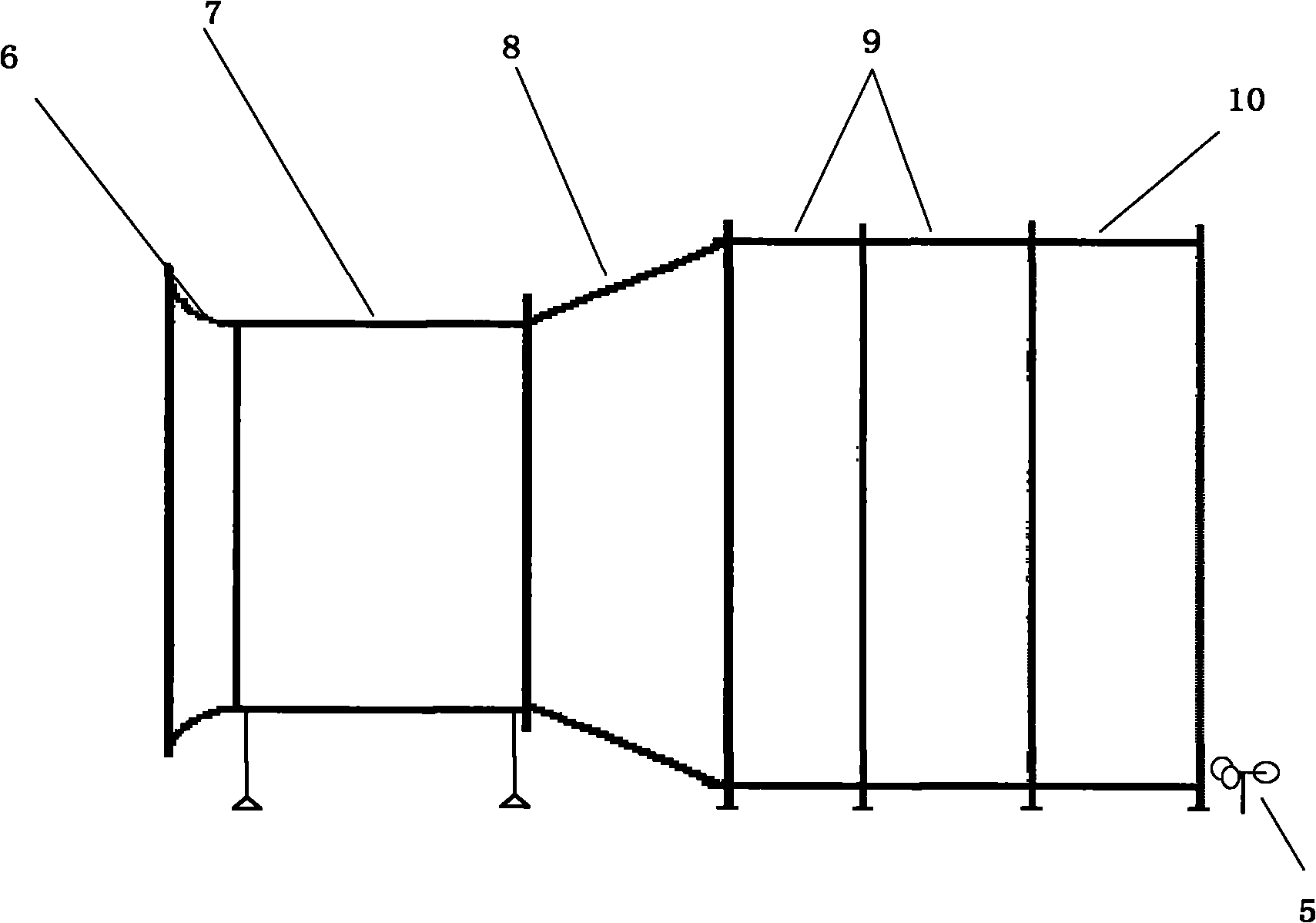

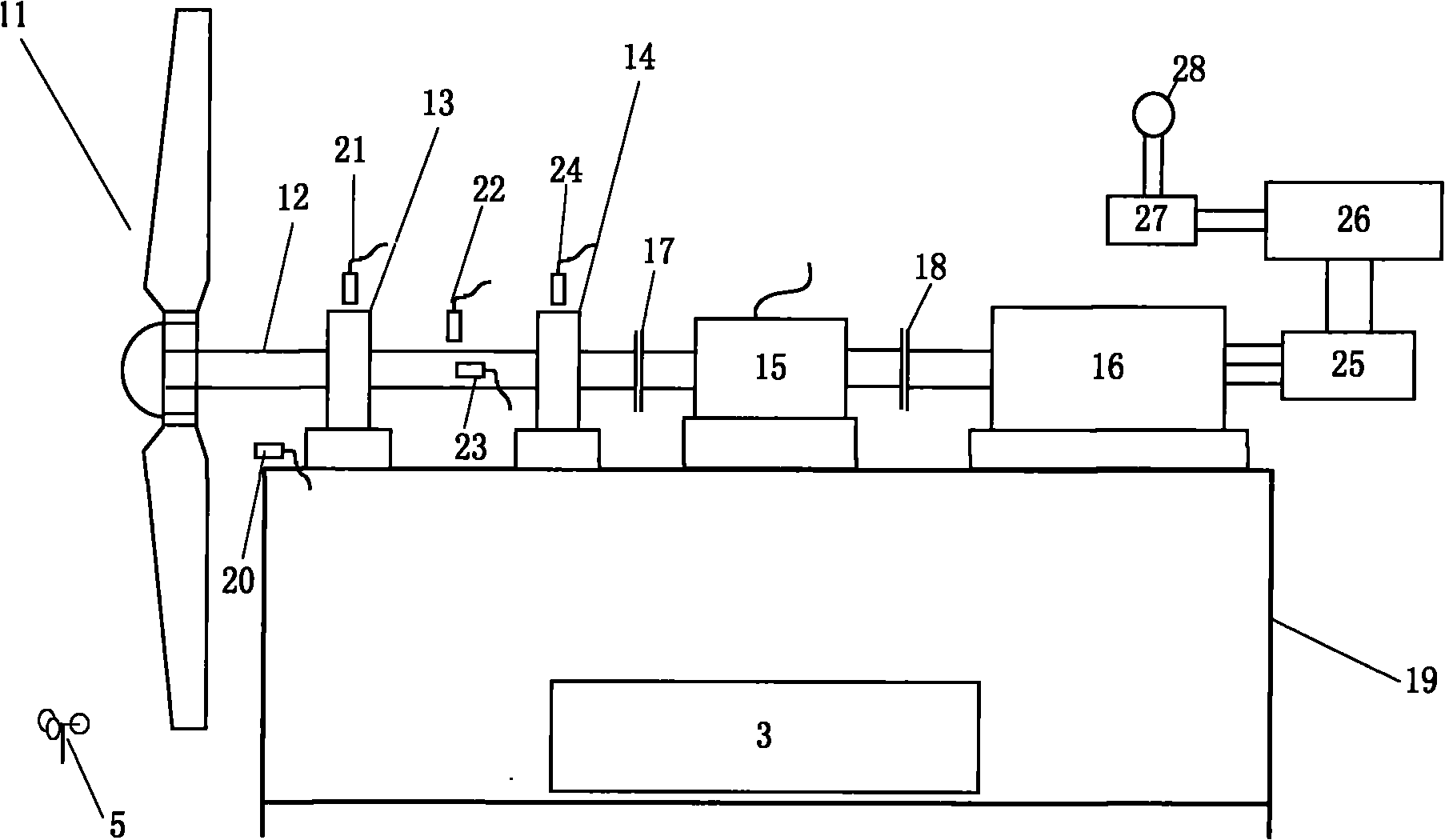

[0022] The structure, working principle and working process of the wind turbine performance analysis and failure experiment system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Wind machine performance analysis and failure experiment system of the present invention are mainly made up of wind tunnel, wind machine experimental device and data analysis and processing system; wherein wind tunnel produces different wind speeds and blows to wind machine experimental device; Driven to rotate, drive the generator to rotate, and generate various performance parameters and vibration parameters; the data analysis and processing system collects the performance parameters and vibration parameters of the wind turbine experimental device, displays, analyzes and stores the various parameters obtained, and can Realize reading of historical data, conversion of data format, etc. The overall structure of the system is as figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com