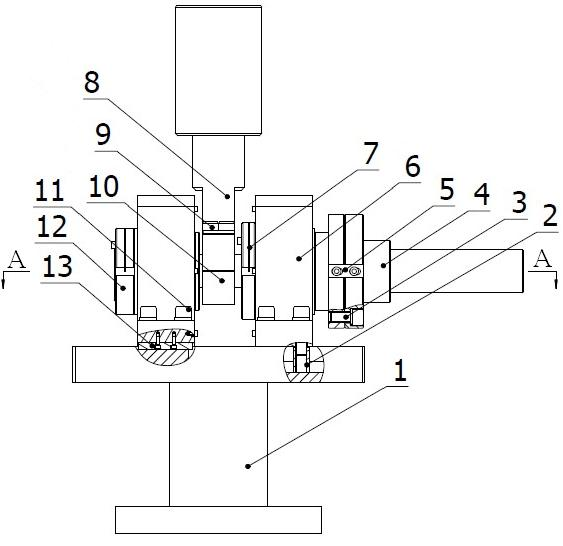

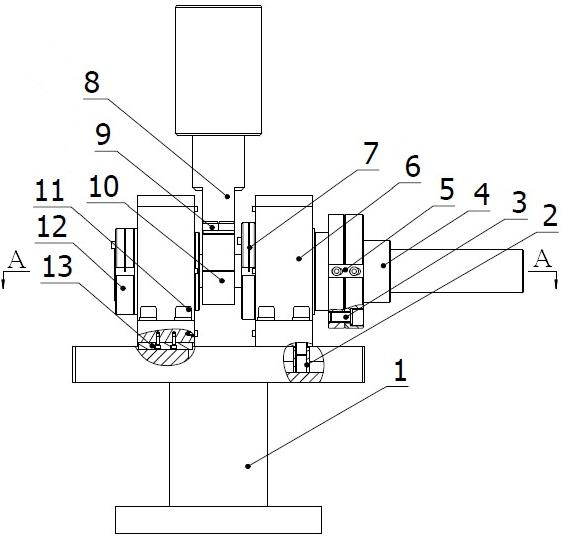

Test detection device for joint bearing

A joint bearing and detection device technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of joint bearing reliability inspection and measurement, and achieve the effect of novel structure, convenient repeated disassembly and assembly, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

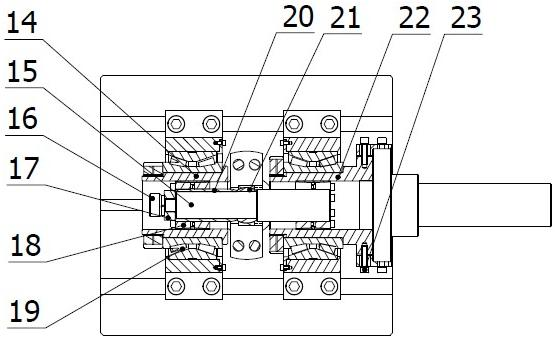

[0008] The guide block 13 is fixedly connected to the bearing seat 6, the bearing seat 6 is slidingly connected to the base 1 through the guide block 13, the two double-row tapered roller bearings 19 are fixedly connected to the two bearing seats 6 respectively, and the rotating sleeve 7 is used to rotate The sleeve 22 is fixed on the double-row tapered roller bearing 19 on the right, and the follower sleeve 14 is fixed on the double-row tapered roller bearing 19 on the left with the follower sleeve back nut 12. The open transition sleeve 20 is installed on the At the left end of the connecting shaft 15, install the opening transition sleeve 20 together with the connecting shaft 15 into the left expansion sleeve 18, and install the left expansion sleeve 18 into the follower sleeve 14. There is an expansion on the right side of the connecting shaft 15 Sleeve 18, put the right expansion sleeve 18 into the rotating sleeve 22, the follower sleeve 14 and the rotating sleeve 22 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com