Full-automatic assembling machine for tapered roller bearing inner components

A technology of tapered roller bearings and inner components, applied in bearing assembly, bearing components, bearings, etc., can solve the problems of high rate of defective products, low efficiency, and high labor intensity of workers, so as to improve production efficiency and reduce labor intensity , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

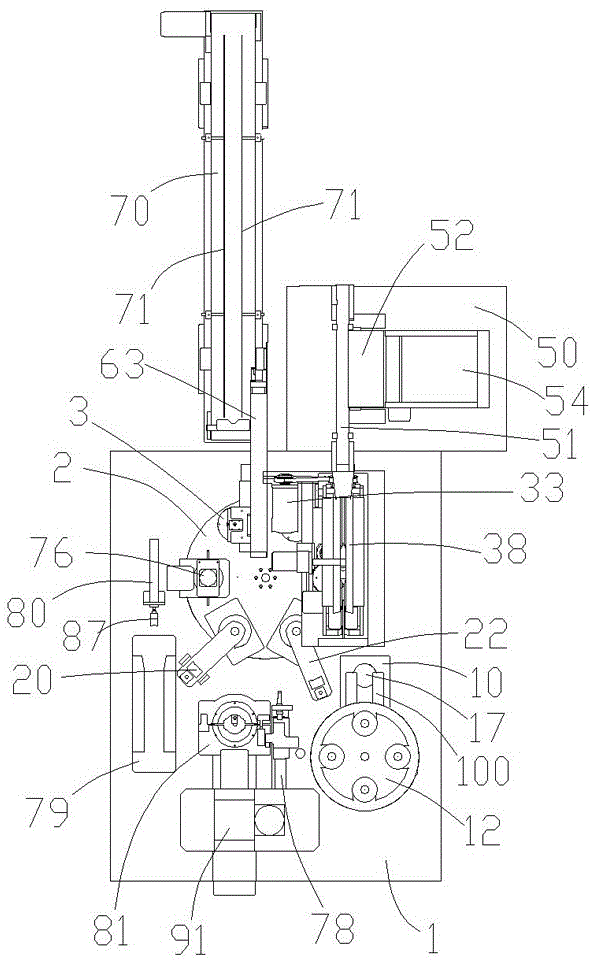

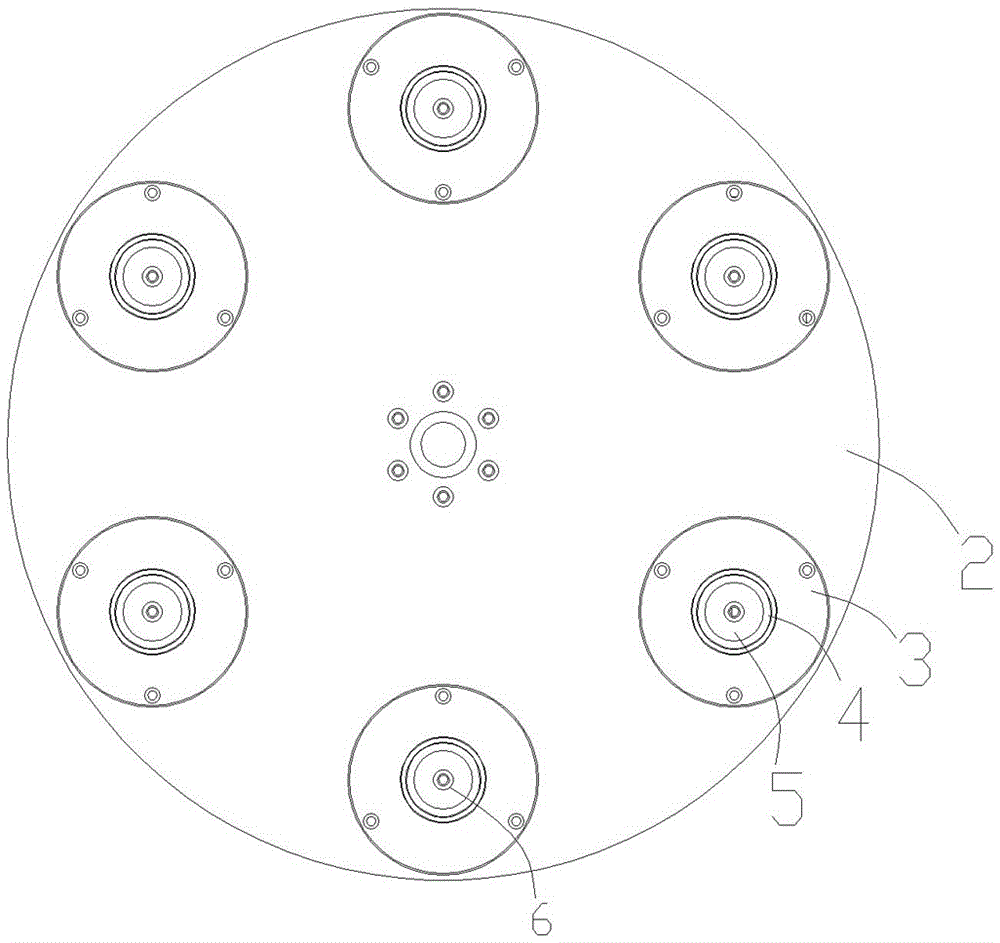

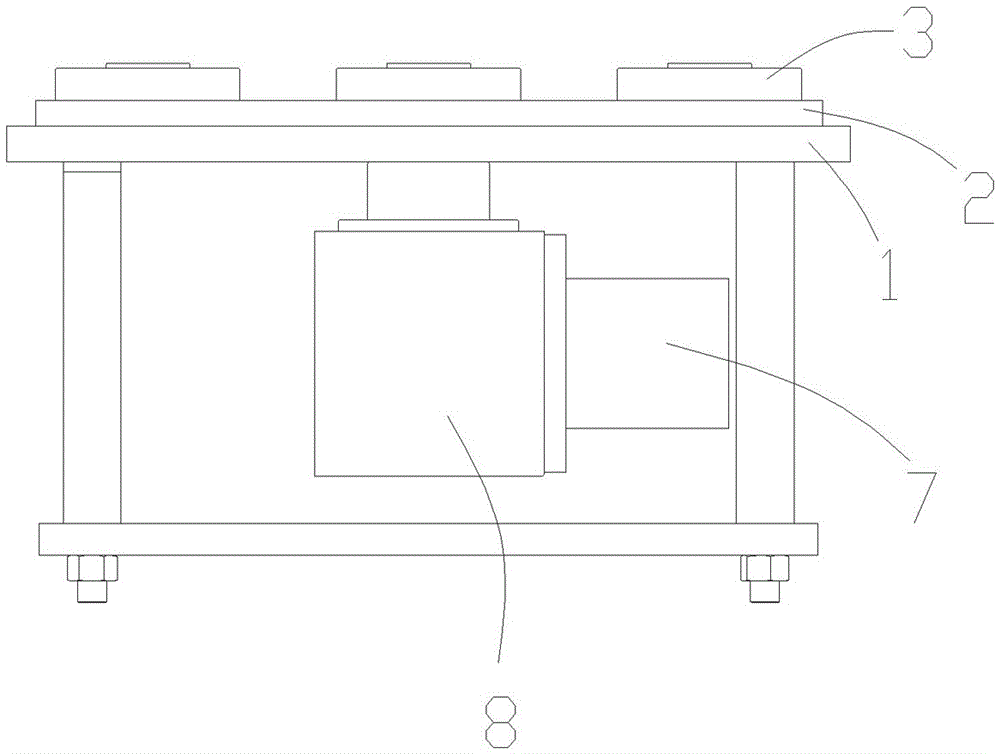

[0037] Such as Figure 1~19 As shown, a fully automatic assembly machine for inner components of tapered roller bearings, including a workbench 1, on which a turntable 2 and a drive mechanism for driving the turntable are arranged, and a number of assembly stations 3 are evenly distributed on the turntable , there are six assembly stations in this embodiment, and the middle of each tooling station is provided with a first annular groove 4 that is sunken downwards, and the center of the bottom of the first annular groove is sunken downwards Form the second annular groove 5, the center of the bottom of the second annular groove extends vertically upwards to form a fixed column 6, the radius of the second annular groove is less than the radius of the first annular groove, the The second ring groove is adapted to the inner component of the bearing, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com