Long glass fiber reinforced hard polyurethane synthetic material sleeper and method for preparing the same

A technology of long glass fiber and rigid polyurethane, which is applied in the direction of rails, other household appliances, household components, etc., can solve the problems of installation accuracy limitation, reduce the amount of consumption, and post-processing difficulties, and achieve easy processing and installation, and improve installation accuracy , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

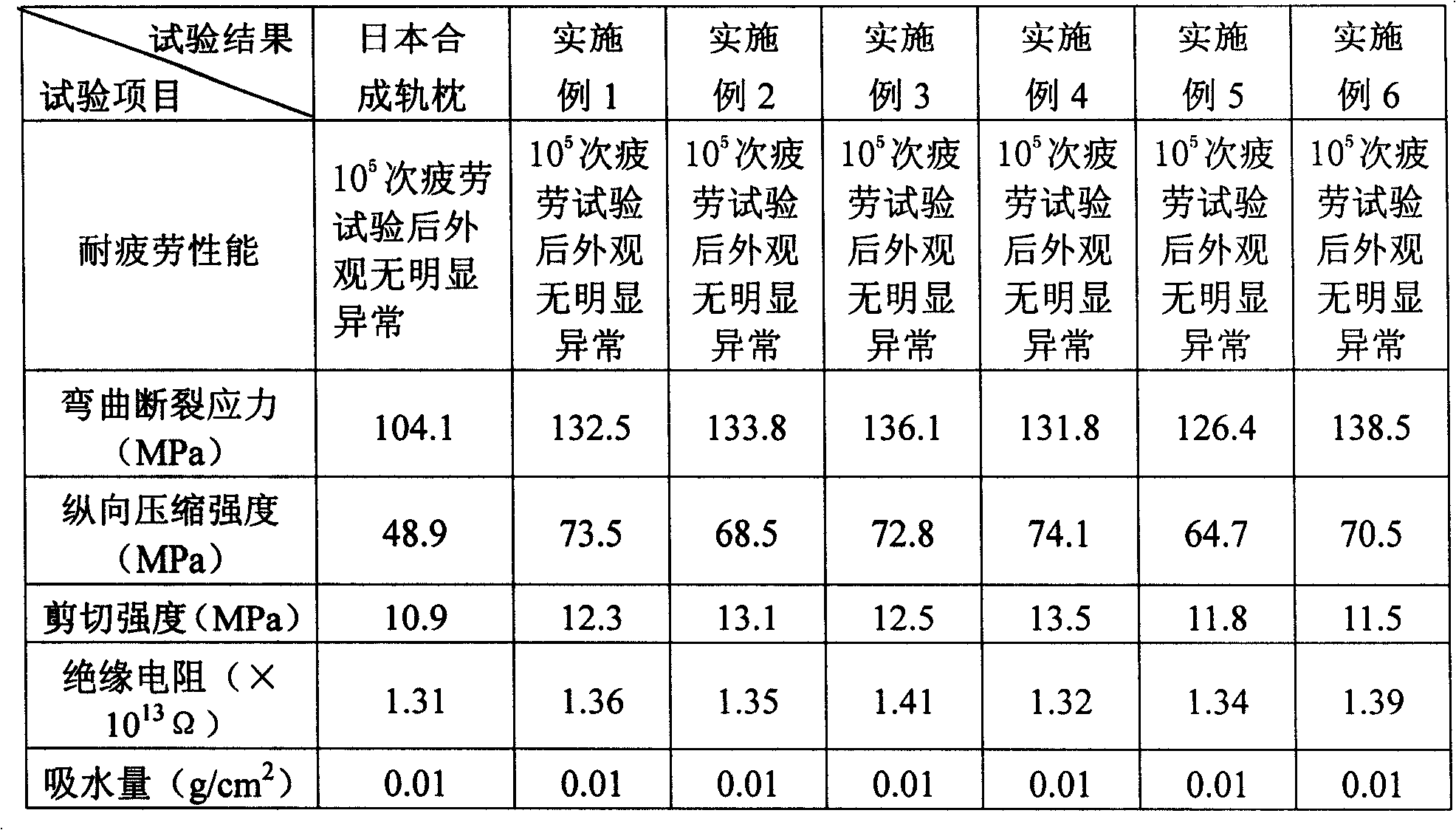

Examples

Embodiment 1

[0030] Configuration of Synthetic Materials

[0031] Polyol A is a polyether polyol with ethylene glycol as an initiator;

[0032] Polyol B is a polyether polyol with glycerol as an initiator;

[0033] Polyol C is a polyether polyol with mannitol as an initiator;

[0034] Polyol D is a polyether polyol taking sucrose as a starter;

[0035] The quaternary ammonium salt catalyst is the quaternary ammonium salt generated by the reaction of triethylenediamine and phosphoric acid;

[0036] The metal salt catalyst is zinc isooctanoate;

[0037] I component polyol composition mass fraction

[0038] Polyol A 8

[0039] Polyol B 52

[0040] Polyol C 30

[0041] Polyol D 10

[0042] The amount of quaternary ammonium salt catalyst is 0.3% of the amount of polyol component in component I

[0043] The amount of metal salt catalyst is 0.05% of the amount of polyol component in component I

[0044] The amount of silicone foam stabilizer is 1.6% of the amount of polyol in component I ...

Embodiment 2

[0058] Configuration of Synthetic Materials

[0059] Polyol A is polyether polyol with ethylene glycol and propylene glycol as initiator;

[0060] Polyol B is a polyether polyol with trimethylolpropane as an initiator;

[0061] Polyol C is a polyether polyol with methyl glucoside as an initiator;

[0062] Polyol D is a polyether polyol taking sucrose as a starter;

[0063] The quaternary ammonium salt catalyst is the quaternary ammonium salt generated by the reaction of pentamethyldiethylenetriamine and formic acid;

[0064] The metal salt catalyst is potassium isooctanoate;

[0065] I component polyol composition mass fraction

[0066] Polyol A 12

[0067] Polyol B 58

[0068] Polyol C 25

[0069] Polyol D 5

[0070] The amount of quaternary ammonium salt catalyst is 0.8% of the amount of polyol component in component I

[0071] The amount of metal salt catalyst is 0.2% of the amount of polyol component in component I

[0072] The amount of silicone foam stabilizer ...

Embodiment 3

[0086] Configuration of Synthetic Materials

[0087] Polyol A is a polyether polyol with diethylene glycol as an initiator;

[0088] Polyol B is a polyether polyol with glycerin and trimethylolpropane as initiators;

[0089] Polyol C is a polyether polyol with methyl glucoside as an initiator;

[0090] Polyol D is a polyether polyol taking sucrose as a starter;

[0091] The quaternary ammonium salt catalyst is the quaternary ammonium salt generated by the reaction of two (2-dimethylaminoethyl) ethers and acetic acid;

[0092] The metal salt catalyst is lead acetate;

[0093] I component polyol composition mass fraction

[0094] Polyol A 8

[0095] Polyol B 22

[0096] Polyol C 40

[0097] Polyol D 30

[0098] The amount of quaternary ammonium salt catalyst is 1.3% of the amount of polyol component in component I

[0099] The amount of metal salt catalyst is 0.5% of the amount of polyol component in component I

[0100] The amount of silicone foam stabilizer is 1.8% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com