Local high-precision printed circuit board and manufacturing method thereof

A printed circuit board, high-precision technology, used in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problem of difficult to meet the drilling requirements of high-end printed circuit boards, insufficient drilling accuracy control, and scrapped boards. and other problems, to achieve the effect of improving the drilling alignment accuracy, reducing the scrap rate, and being easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

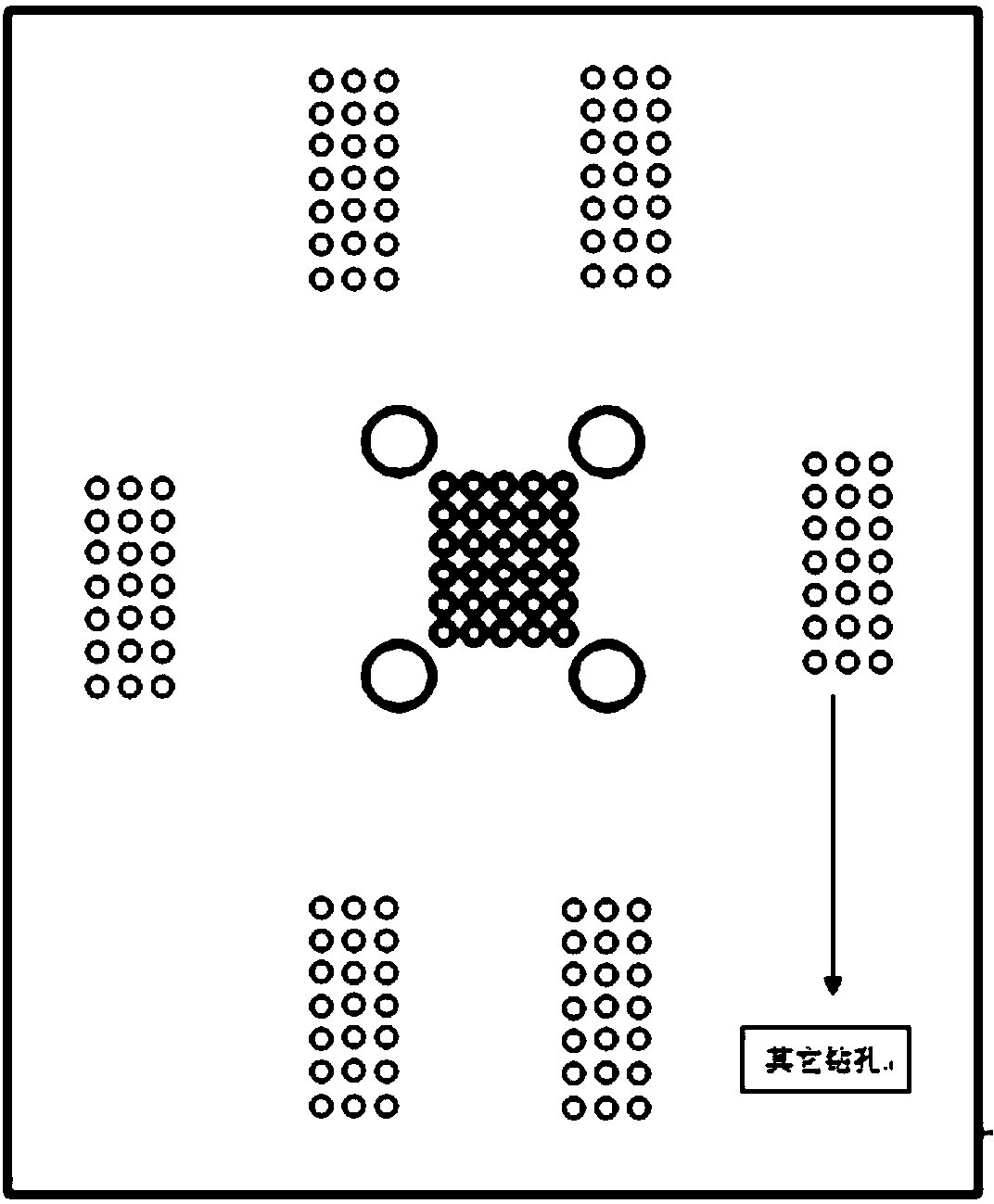

[0032] This embodiment is a method for preparing a local high-precision printed circuit board. The entire printed circuit board is divided into a high-precision pattern area and a common pattern area. The number of layers of the printed circuit board is 24. The distance from the hole to the conductor in the precision pattern area is 3.5 mils.

[0033] The preparation method includes the following steps: inner layer pattern making, pressing, drilling, outer layer dry film and post-processes;

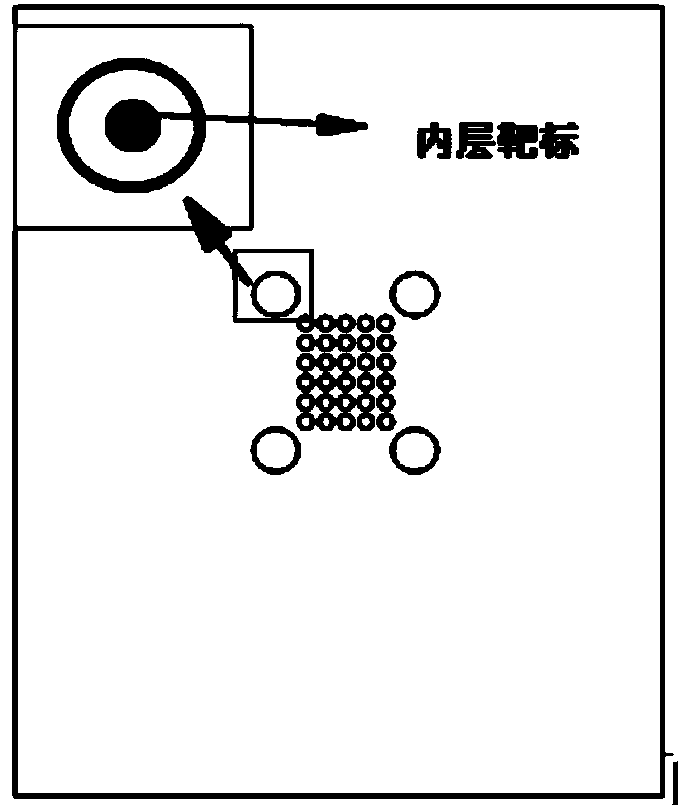

[0034] In the step of making the inner layer graphics, 4 positioning targets (such as figure 1 Shown);

[0035] In the pressing step, the Pin-Lam process is used for production;

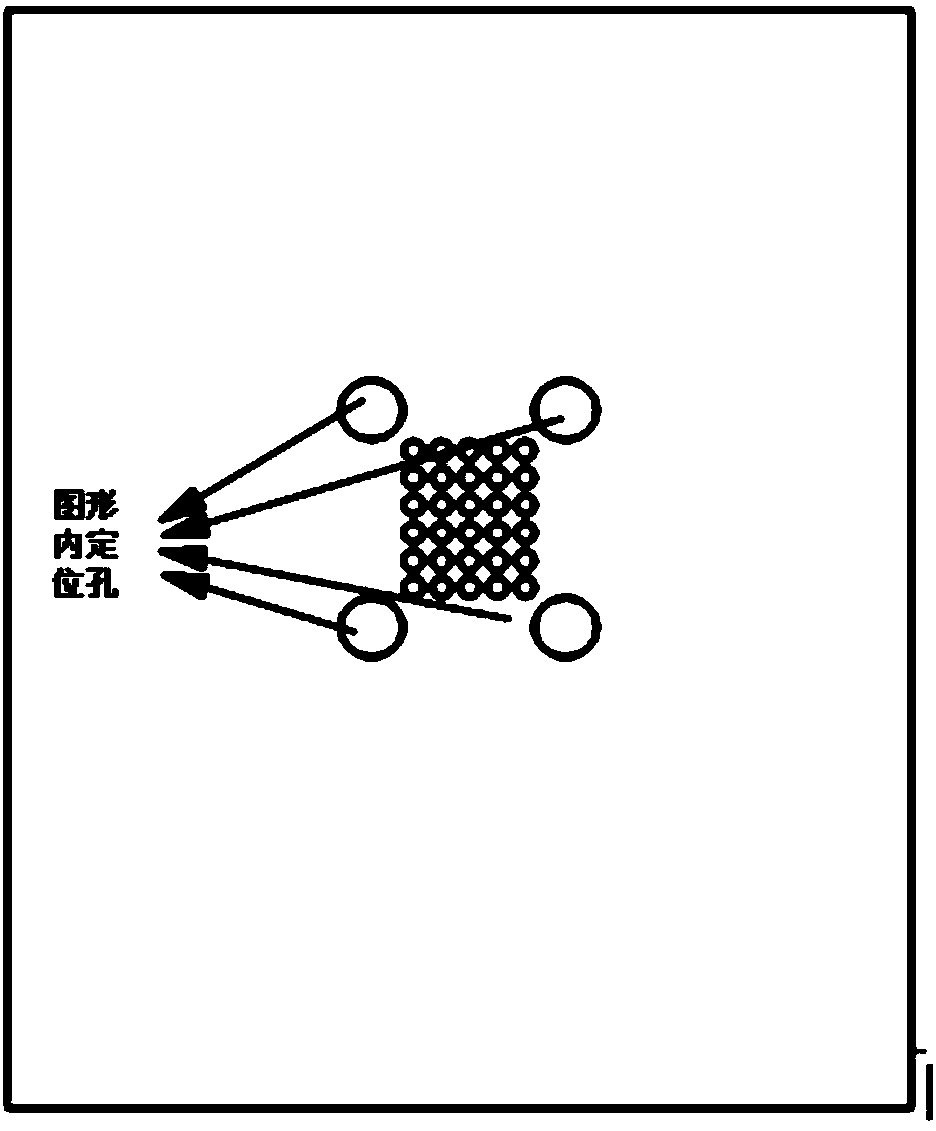

[0036] After pressing, use the inner layer positioning target of the graphic to determine the positioning hole in the graphic, and then use the X-RAY target punching machine to punch out the positioning hole in the graphic (such as figure 2 As shown), the positioning holes in the graph are non-metallized holes with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com