Multi-axis motion control system

A multi-axis motion and control system technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of difficult software and hardware upgrade, poor openness, low cost, etc., to achieve universal, high-precision, real-time satisfaction desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

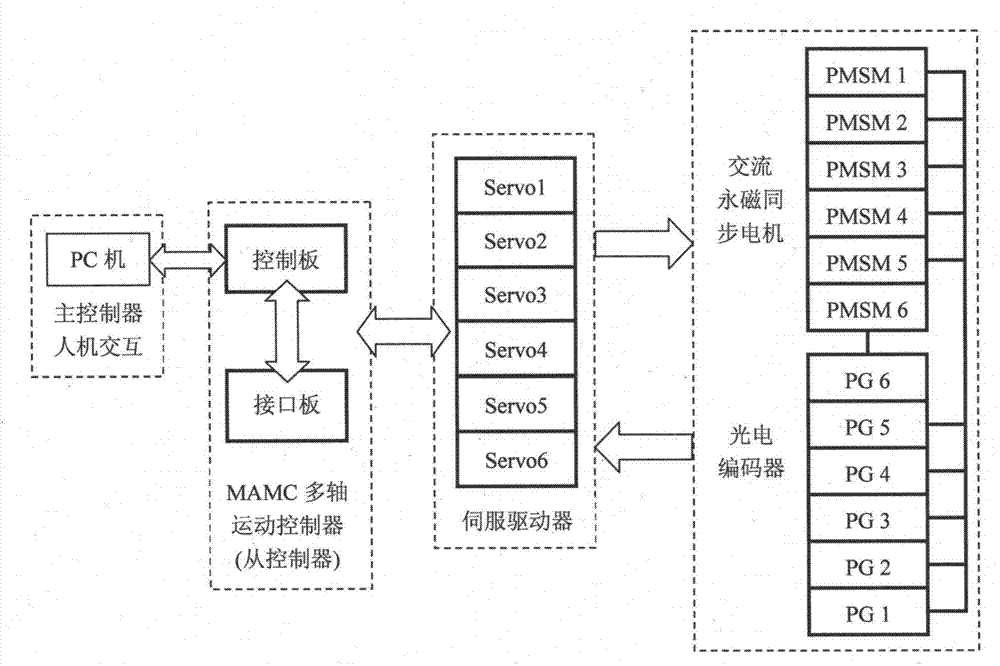

[0030] figure 1 The structural diagram of the multi-axis motion control system provided by the present invention, in which the PC is used as the main controller to complete the trajectory planning of the task space and the joint space, the command cycle interpolation of the joint space trajectory, virtual teaching, real-time status display of the robot pose, Task-level functions such as teaching instruction interpretation, human-computer interaction, and network communication. MAMC (Multi-Axis Motion Controller) multi-axis motion controller (slave controller) is the core device for performing motion control tasks in the entire system, acting as a bridge between the master controller and the motor servo driver, and executing the target position control command of the PC , undertake servo-level tasks such as servo periodic interpol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com