Device and method for maintaining stable operation of strip steel for cold-rolled strip steel production unit

A stable operation, cold-rolled strip technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as deviation, strip torsion, jitter, etc., to improve productivity, eliminate torsion and jitter, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

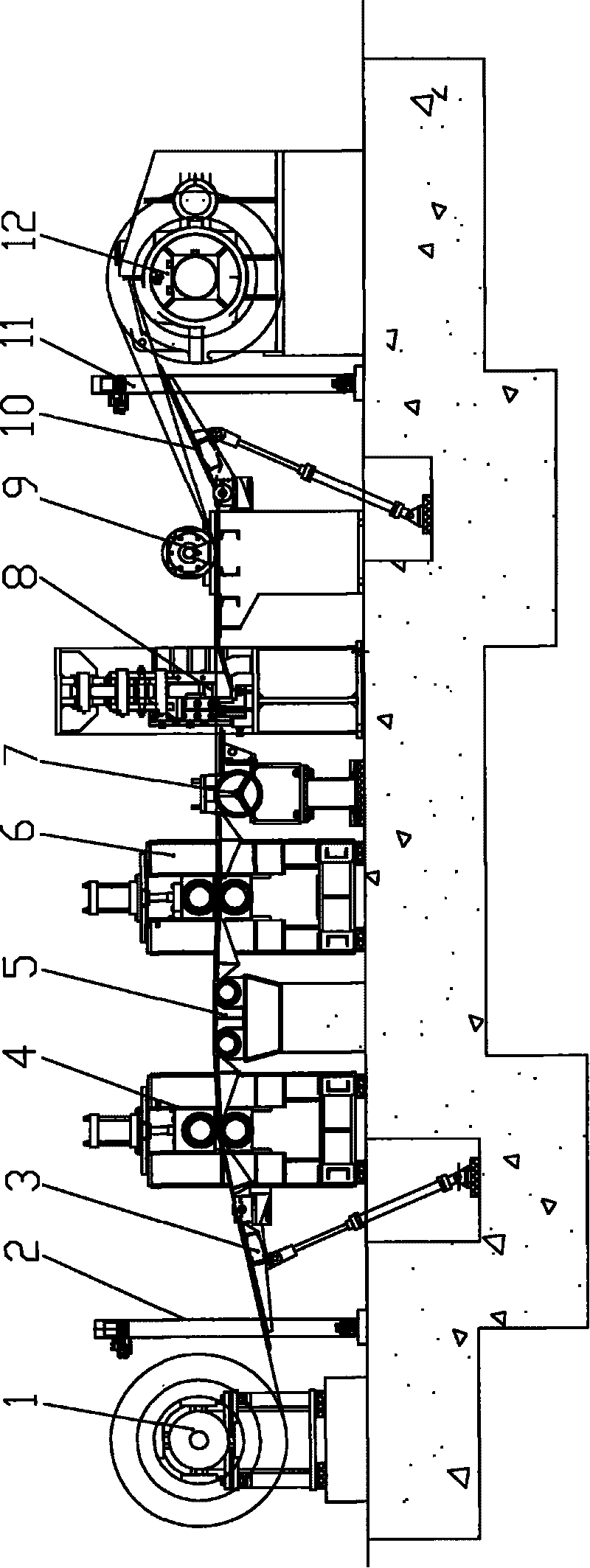

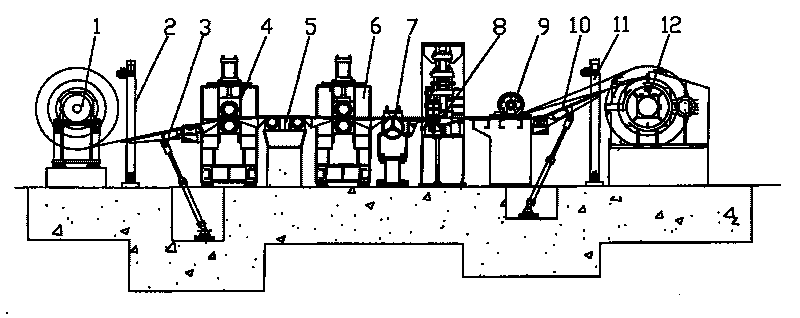

[0017] The cold-rolled strip production unit provided by the present invention maintains the method for the stable operation of the strip, and its steps include:

[0018] The first step is to start from the tension control to ensure the stable operation of the strip: install an uncoiler at the head of the unit, a coiler at the tail of the unit, and a high-precision encoder for the uncoiler and the coiler;

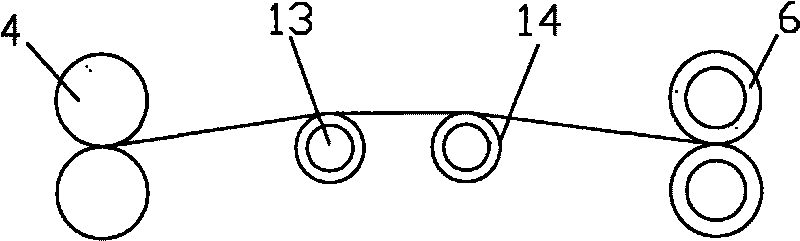

[0019] The second step is to prevent the twisting and shaking of the strip: add tension rollers to the unit. The tension rollers include left and right rollers of the same height. The elevation of the tension roller surface is higher than the strip passing line. , the strip forms a wrap angle at the entrance and exit of the tension roller, tensions the strip, and makes the strip run stably;

[0020] The third step is to prevent the deviation of the strip: add a CPC device after the uncoiler of the unit, the CPC device is an automatic centering and deviation correction contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com