High-speed environmental-friendly tinning machine and smooth-transition method

A tin wrapping machine, environmental protection technology, applied in the direction of coating, metal material coating process, hot-dip plating process, etc., can solve the problems of loss of cost advantage, fierce market competition, etc., and achieve not easy broken wire, long service life, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

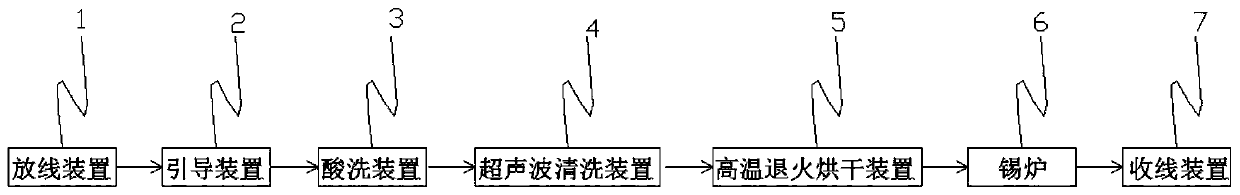

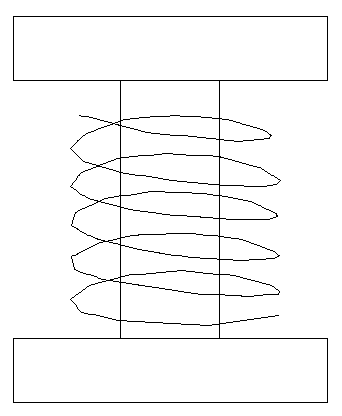

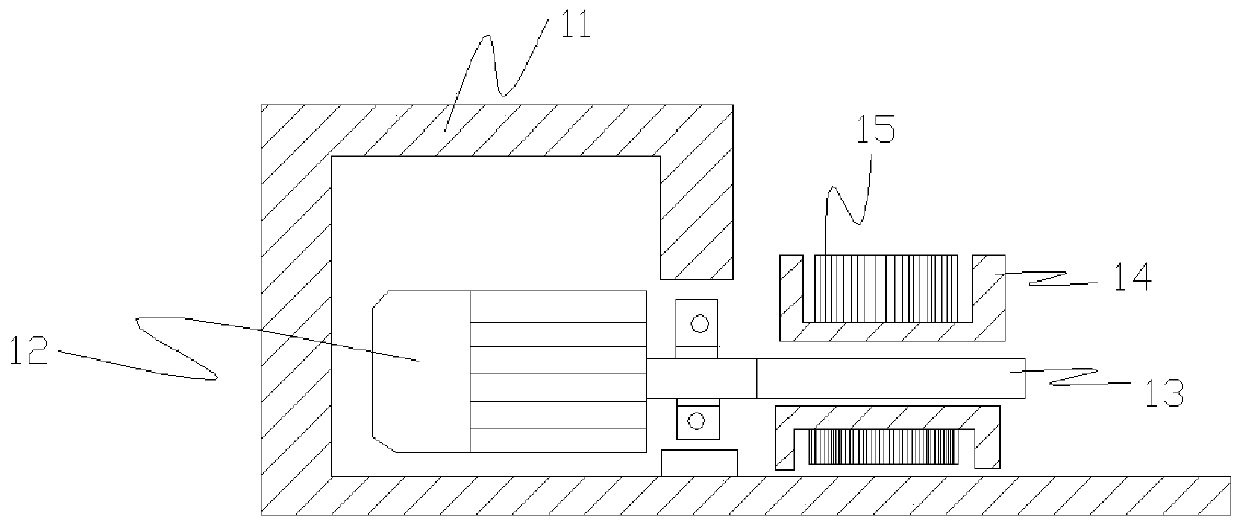

[0044] Such as Figure 1 to Figure 15 As shown, the high-speed environmental protection tin wrapping machine of the present invention includes a discharging device 1, a guiding device 2, a pickling device 3, an ultrasonic cleaning device 4, a high-temperature annealing drying device 5, a tin furnace 6 and a wire take-up device 7 connected in sequence The guide device 2 is provided with a first line-passing area, the pickling device 3 is provided with a second line-passing area, the ultrasonic cleaning device 4 is provided with a third line-passing area, and the high-temperature annealing drying device 5 is provided with a fourth line-passing area, The tin furnace 6 is provided with a fifth line-passing area; the first line-passing area, the second line-passing area, the third line-passing area, the fourth line-passing area and the fifth line-passing area are on the same horizontal plane and cooperate to form a straight-line line-passing area . The traditional tinning machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com