Water washing and hot drawing device for fiber tow spinning

A fiber tow and thermal drafting technology, which is applied in the field of fiber tow spinning with water washing and thermal drafting devices, can solve the problems of damaged fiber tow, low drafting efficiency, etc. Broken wire, beneficial to strengthen the effect of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

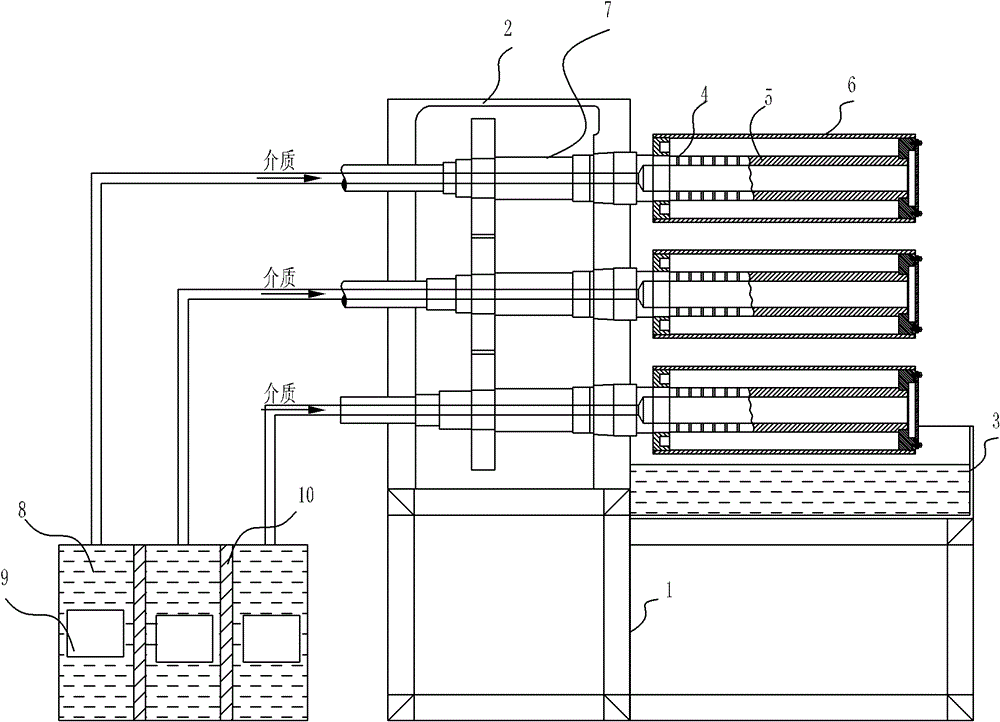

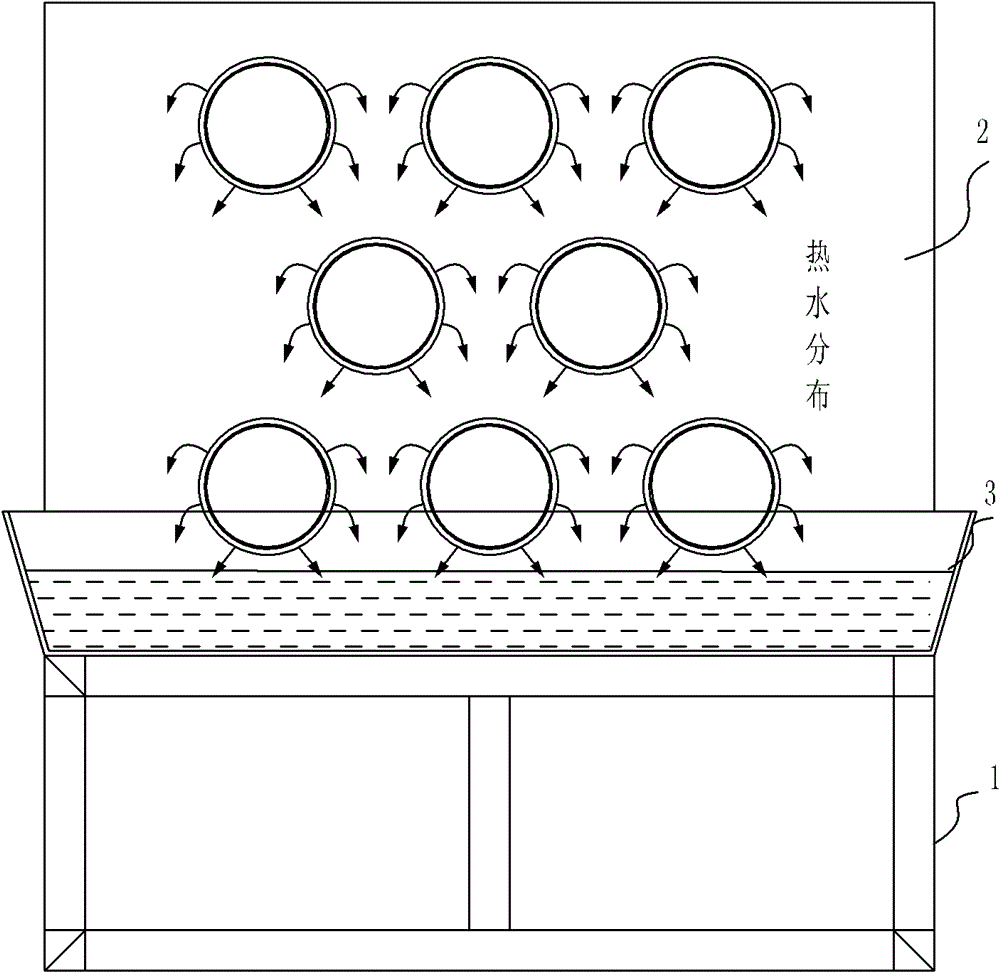

[0020] Such as figure 1 , figure 2 The schematic diagram of the structure of the fiber tow spinning water washing and hot drawing device, including the base 1, the box body 2, the transmission device 7 fixed on the box body and placed in the box body, the heat source supply device 8 and the base set on the box body Above the hot water collection tank 3, the transmission device 7 includes a transmission shaft 5 and a transmission roller 6 installed on the transmission shaft 5. A plurality of liquid outlet holes 4 are evenly distributed on the transmission shaft 5. The material of the transmission roller 6 is porous material. The heat source supply device 8 supplies hot water to the transmission shaft. The porous material is made of stainless steel, nickel, titanium and other metal alloy materials. The temperature of the hot water supplied by the heat source supply device is 50-99°C.

[0021] The present invention uses porous material as the roller surface of the drafting de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com