A kind of preparation method of PVDC composition for spinning

A composition and spinning technology, applied in the field of preparation of PVDC compositions, can solve the problems of poor thermal stability and flame retardancy of PAN-based fibers, poor heat resistance of protein-based fibers, and high thermal shrinkage, and achieve spinning performance and Good thermal stability during processing, improved thermal stability and processing performance, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for spinning PVDC compositions, comprising the following steps:

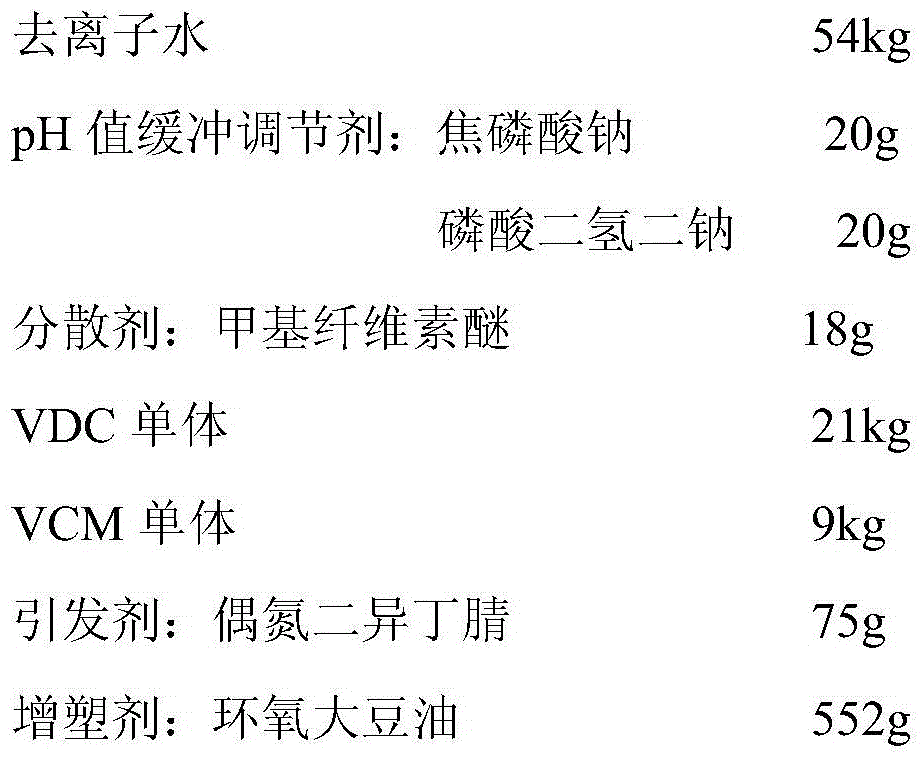

[0032] (1) Prepare the reaction raw materials for subsequent use, and the raw material formula is as follows:

[0033]

[0034]

[0035] (2) Prepare pH buffer regulator aqueous solution and dispersant aqueous solution: Sodium pyrophosphate 20g and disodium dihydrogen phosphate 20g are mixed with deionized water 2kg to make pH buffer regulator aqueous solution; Methyl cellulose ether 18g, Use 9kg of deionized water to prepare an aqueous dispersant solution;

[0036] (3) Put 5kg of deionized water into a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, double-layer two-page 45° inclined paddle), seal the kettle for pressure test and vacuumize, then add VDC Monomer, VCM monomer, azobisisobutyronitrile, dispersed at 120rpm / min for 10 minutes, then added aqueous solution of dispersant, aqueous solution of pH buf...

Embodiment 2

[0041] A preparation method for spinning PVDC compositions, comprising the following steps:

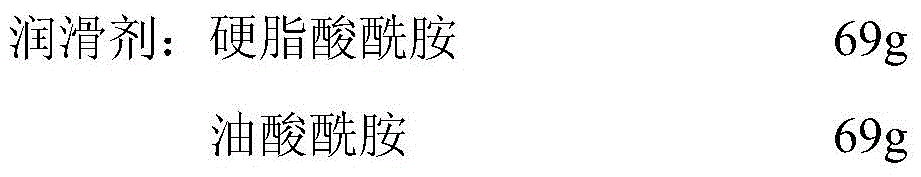

[0042] (1) Prepare the reaction raw materials for subsequent use, and the raw material formula is as follows:

[0043]

[0044]

[0045] (2) Preparation of pH value buffer regulator aqueous solution and dispersant aqueous solution: sodium pyrophosphate 20g and disodium dihydrogen phosphate 20g are mixed with deionized water 2kg to make pH value buffer regulator aqueous solution; hydroxypropyl methylcellulose Ether 24g, mixed with deionized water 9kg to make dispersant aqueous solution;

[0046] (3) Add 5kg of deionized water into a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, aspect ratio 2:1, double-layer two-page 45° inclined paddle), seal the kettle for pressure test, add VDC unit after vacuuming Body, VCM monomer, dibenzoyl peroxide, after dispersing at 140rpm / min for 10 minutes, add dispersant aqueous solution, pH value buffer reg...

Embodiment 3

[0051] A preparation method for spinning PVDC compositions, comprising the following steps:

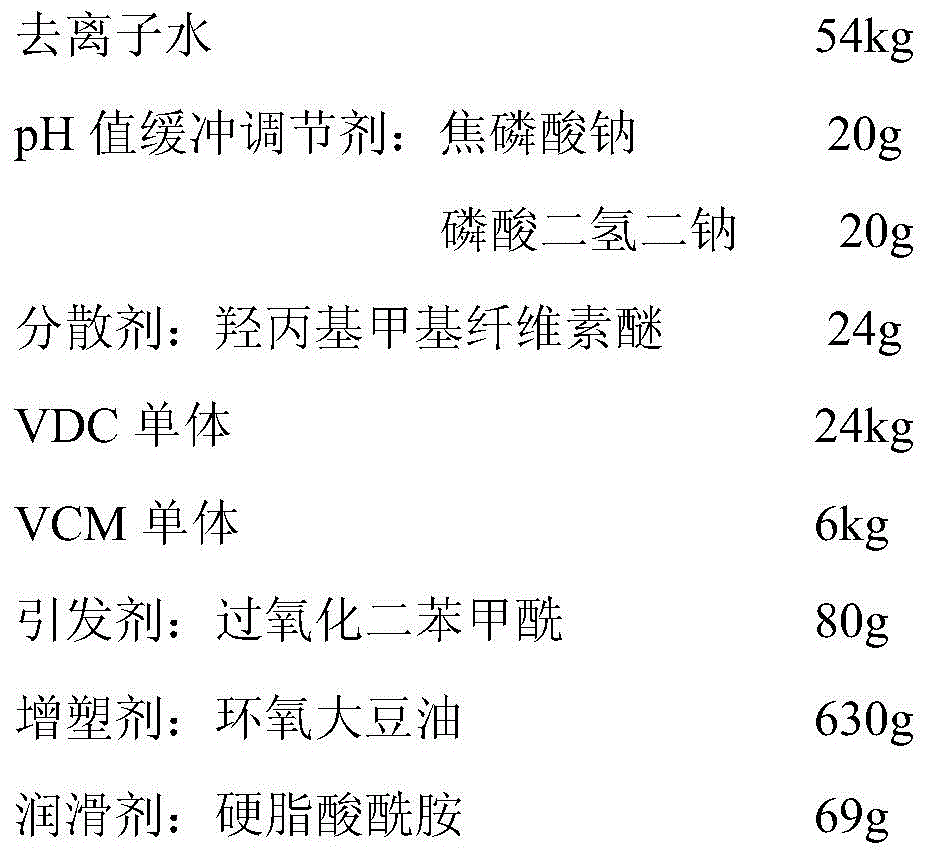

[0052] (1) Prepare the reaction raw materials for subsequent use, and the raw material formula is as follows:

[0053]

[0054] (2) Preparation of pH value buffer regulator aqueous solution and dispersant aqueous solution: sodium pyrophosphate 18g and sodium dihydrogen phosphate 12g are mixed with deionized water 2kg into pH value buffer regulator aqueous solution; hydroxypropyl methyl cellulose ether 24g, mixed with 9kg deionized water to make aqueous dispersant solution;

[0055] (3) Put 5kg of deionized water in a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, double-layer two-page 45° inclined paddle), seal the kettle for pressure test and vacuumize, and then add VDC monomer , VCM monomer and lauryl peroxide were dispersed at a speed of 130 rpm / min for 10 minutes, then an aqueous dispersant solution, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com