Flat waste wire recycling and drawing process and wire-drawing pay-off mechanism

The technology of waste flat wire and flat wire is applied in the field of waste flat wire recycling drawing process and wire drawing pay-off mechanism. Good, conducive to fine drawing, high filament quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

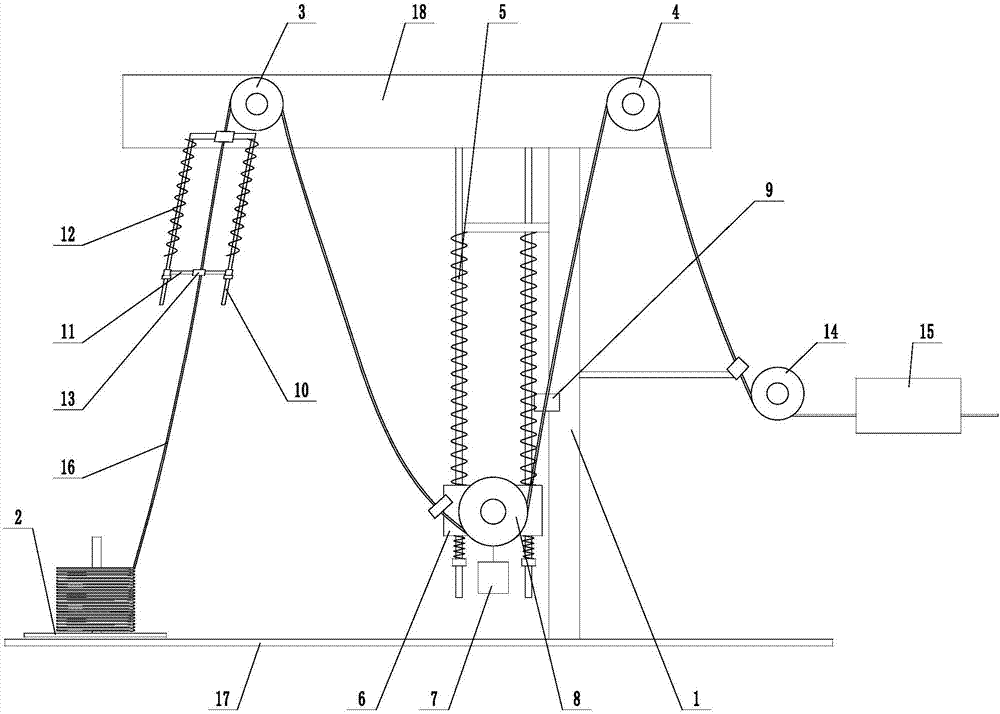

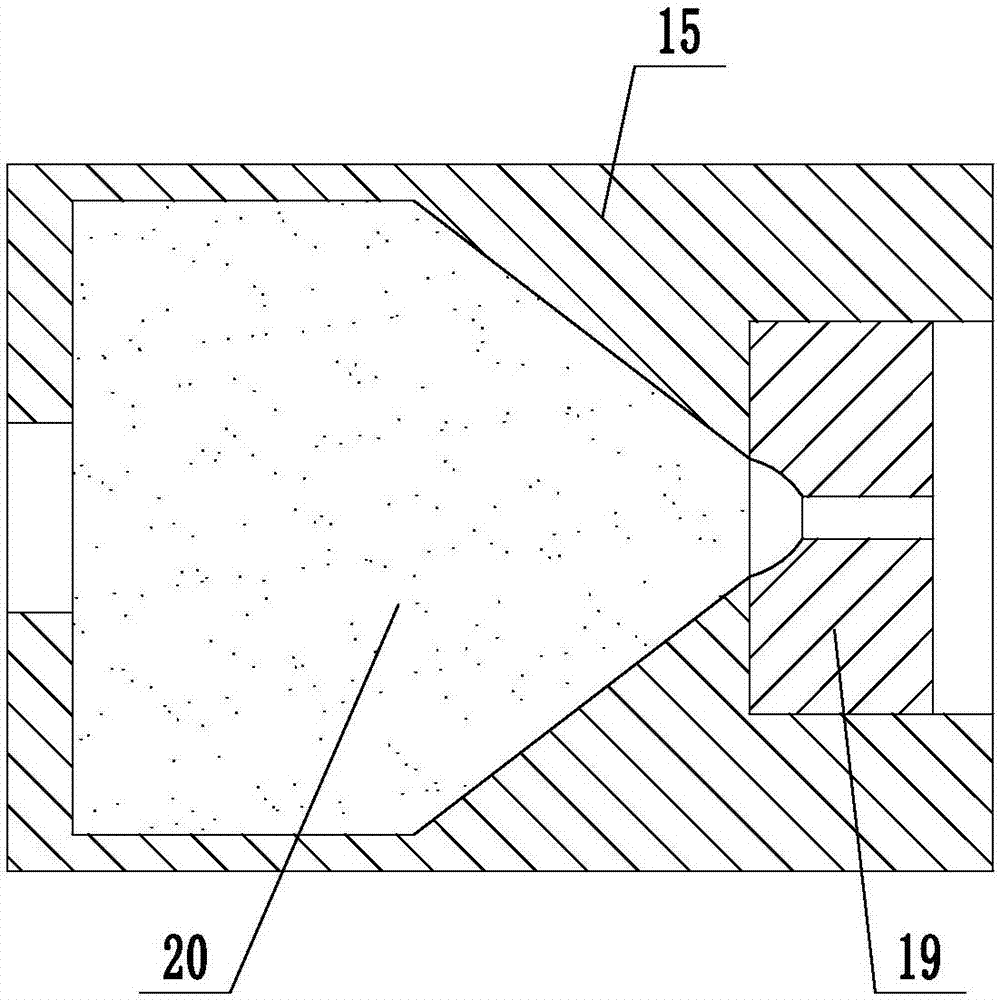

[0023] Embodiment: a waste flat wire recycling drawing process, comprising the following steps: a, butt welding the recovered waste wire into a linear shape; b, pressing the waste wire, placing the butt welded waste wire on a press for pressing into waste flat wire; c, rough drawing of waste flat wire, and the first wire drawing operation of waste flat wire through a wire drawing machine; d, take-up, after rough drawing of waste flat wire, the winding is wound on the pay-off reel; e, annealing Soften, put the pay-off reel that waste flat wire is housed into annealing furnace and soften; f, take out the pay-off reel in the annealing furnace, air-cool waste flat wire; After the waste flat wire is laid out, the surface oxide layer is removed by the peeling wheel; h, the waste flat wire is finely drawn, and the waste flat wire is sent to the wire drawing machine for fine cold drawing, and after the wire drawing is completed, it is wound on the take-up reel for take-up.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com