Magnetic shuttle movement aid unit of circular weaving machine

A circular loom and shuttle technology, which is applied in the field of the magnetic shuttle assisting device of the circular loom, can solve the problems of easy wire breakage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

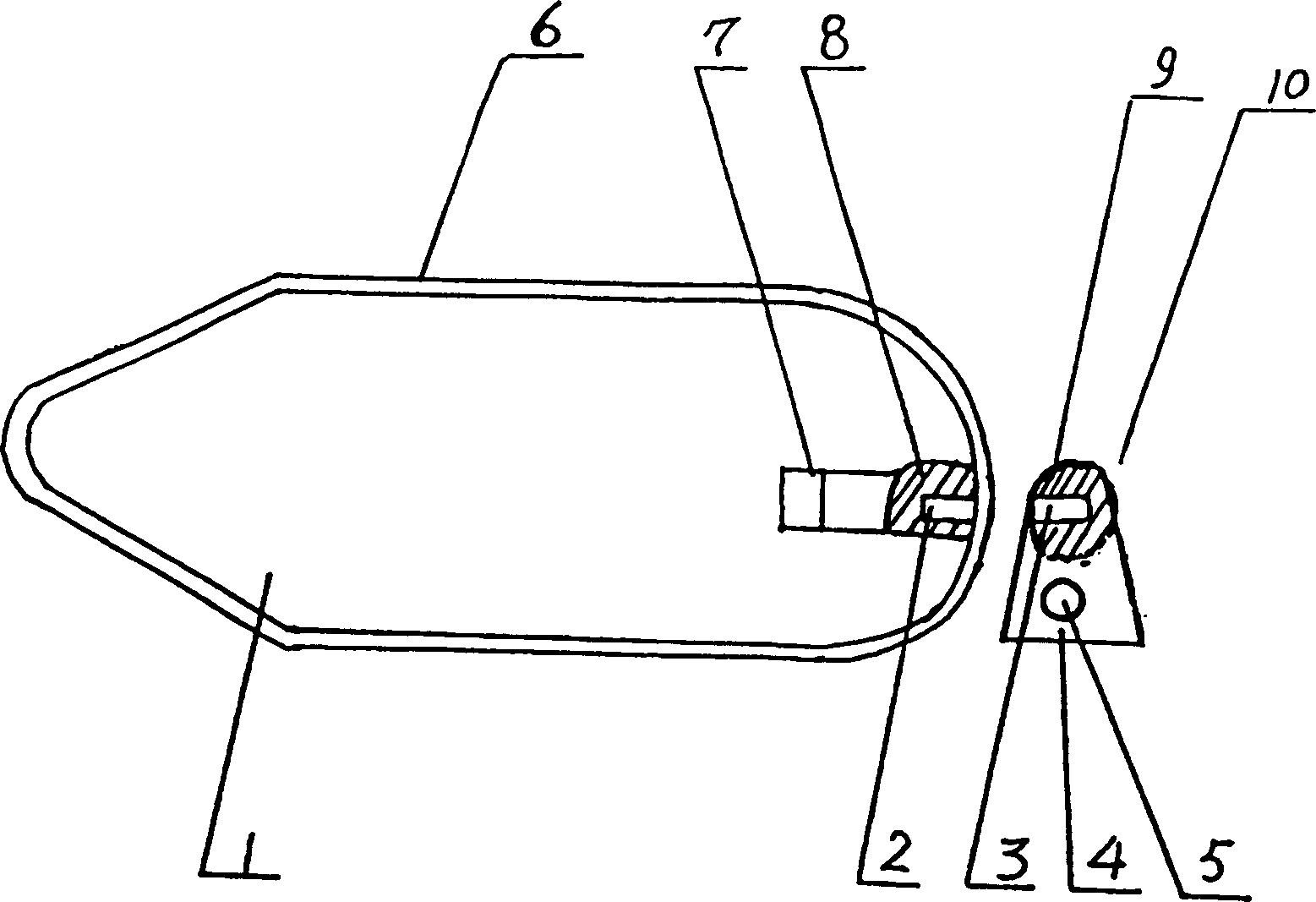

[0005] The present invention and its beneficial effects will be further described below in conjunction with the embodiments and accompanying drawings. figure 1 It is a schematic diagram of the structure of this embodiment. like figure 1 As shown, a magnetic shuttle auxiliary device for a circular loom, the shuttle 1 is arranged in the circumferential track, the push block 4 is connected with the main shaft through the push rod 5, there is a permanent magnet 2 at the tail of the shuttle 1, and the permanent magnet 2 is fixed on the push block 4. Magnet 3, two adjacent magnetic poles of permanent magnet 2 and permanent magnet 3 have the same name as magnetic poles. Also have a non-magnetic wire guide frame 6 to be contained in the periphery of shuttle 1, and an aluminum alloy integral back support 7 is also housed at the shuttle 1 afterbody, and its front part of described back support 7 is a large roller support. Load onto eccentric fixed wheel 8 above rear support 7. The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com