Antistatic bamboo charcoal fiber for underwear

A bamboo charcoal fiber, antistatic technology, applied in the field of textiles, can solve the problems of poor shape retention and stretchability of natural fibers, incapable of power and other problems, and achieve the effect of enhancing antistatic effect, reducing deformation and alleviating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of antistatic bamboo charcoal fiber for underwear, comprising,

[0043] The carbonization process of carrying out high-temperature carbonization treatment on moso bamboo; the homogenization process of bamboo charcoal obtained by carbonization; the spinning stock solution preparation process; and, the spinning process;

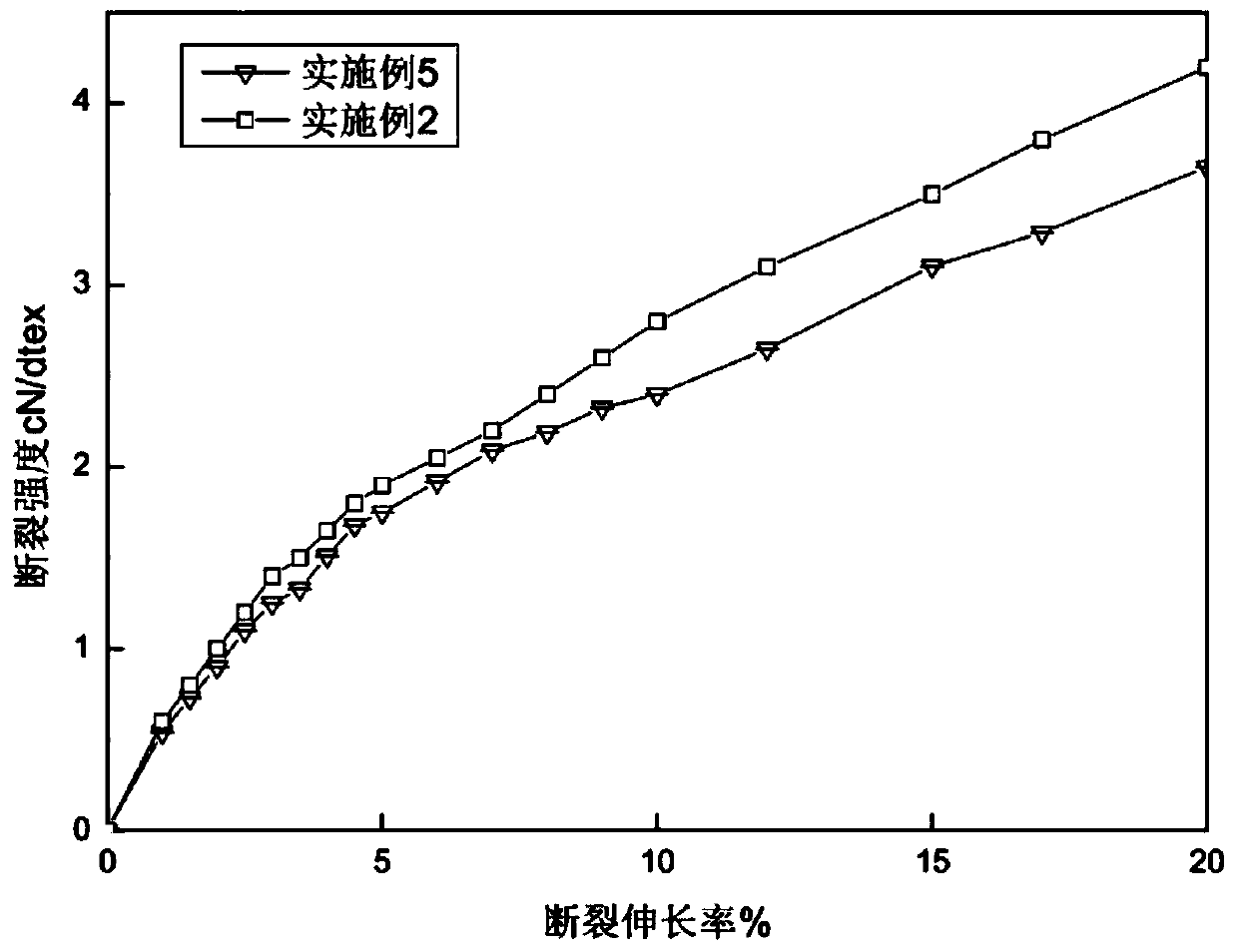

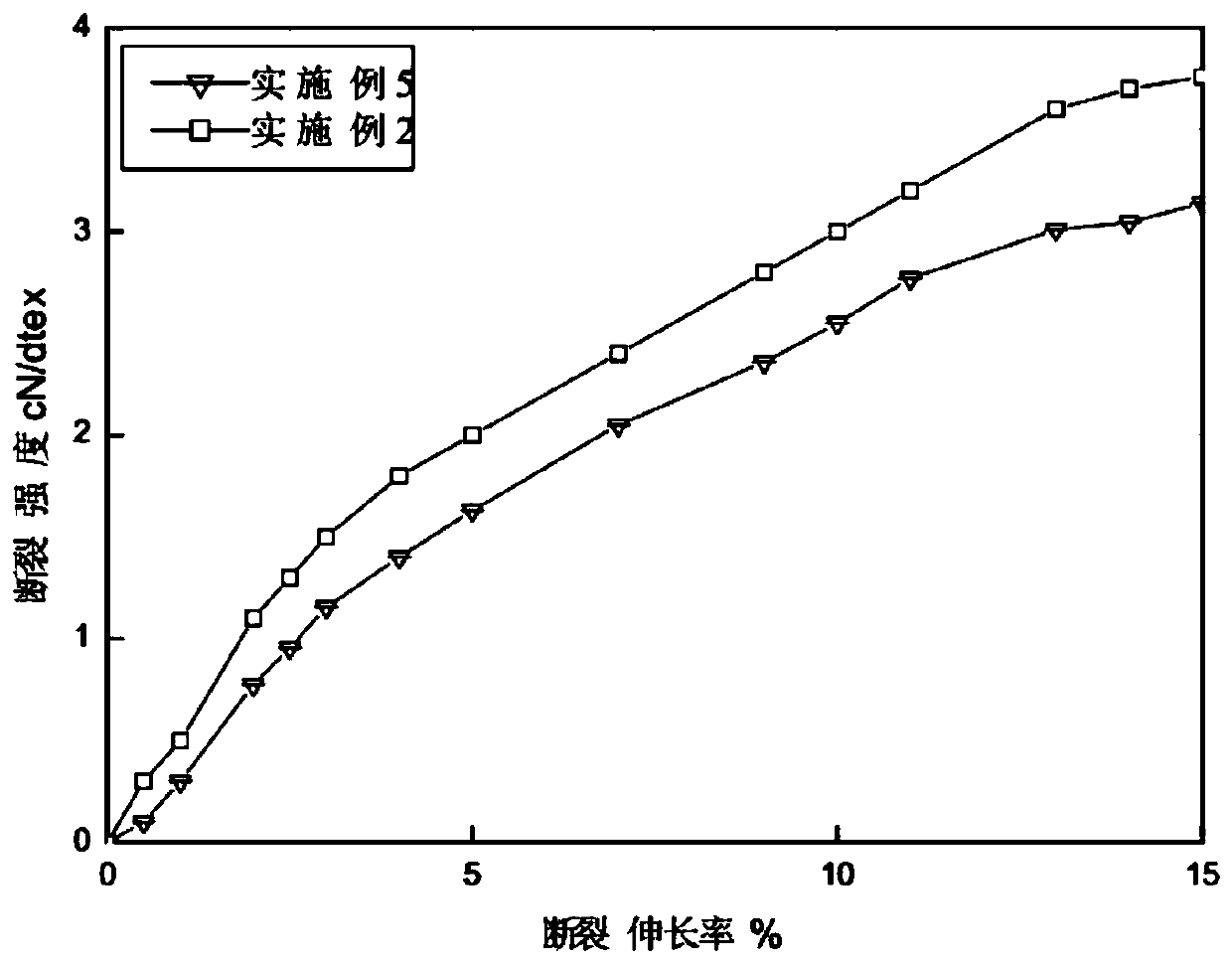

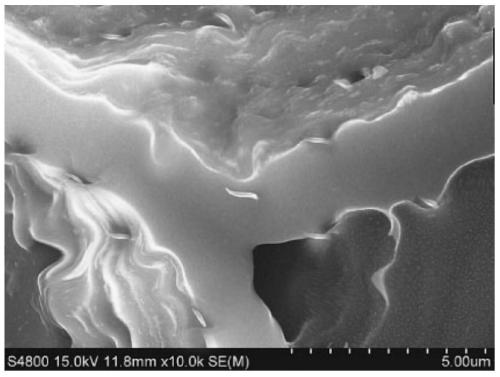

[0044] The dry strength at break of the bamboo charcoal fiber obtained in the above spinning process can reach 2.0-4.5 cN / dtex, and the wet strength at break can reach 1.8-3.8 cN / dtex. In this method, the bamboo charcoal is subjected to ultrafine treatment to form a micropowder to the nanometer level, and then the nanoscale bamboo charcoal is added to the stock solution formed by cellulose, and the fiber is prepared by the textile process, which retains the adsorption, deodorization, and Moisture absorption and perspiration, heat storage and warmth, antibacterial and anti-mildew and good far-infrared and negative ion emission, anti...

Embodiment 1

[0069] The preparation of one of the products of polymer A is specifically realized through the following steps:

[0070] 1) Take adipic acid and place it in 2-3 times the amount of thionyl chloride solution, heat it in a water bath to 30-50° C., remove the solvent, and place the obtained precipitate in a three-component solution containing 2-10% by weight In the acetonitrile solution of ethylamine and 1-15% 4-dimethylaminopyridine, then dropwise add phenylenediamine thereinto, and stir slowly, after the reaction is complete, wash with dilute hydrochloric acid, after removing the solvent, namely the above Chinese formula Blocks of (IIb);

[0071] 2) Add serine and Boc anhydride to tetrahydrofuran solution containing potassium hydroxide, overnight at 0-4°C, then add the above-mentioned block to it, and add 5-8 times the amount of polyphosphoric acid solution, and then place on ice in the bath for 30-60 minutes, then raise the temperature to 80-95°C and react for 1-3 hours to o...

Embodiment 2

[0081] The preparation method of antistatic bamboo charcoal fiber for underwear, its concrete steps are as follows:

[0082] 1) Choose moso bamboo more than 5 years old, keep the temperature at 160°C and dry for 6 days, then raise the temperature to 360°C for pre-carbonization for 4 days, then raise the temperature to 880°C for 5 days, cool to obtain block bamboo charcoal;

[0083] 2) Place the block bamboo charcoal in the suspension containing the photocatalyst of 0.35% by weight, and then use a dose of 30Gy 60 Co-gamma ray irradiation for 45s, after completion, take out and dry, and the photocatalyst suspension also contains 0.06% glycine and 0.08% benzenesulfonic acid by weight;

[0084] 3) First crush the block bamboo charcoal to a particle size of 10mm or below and then carry out jet milling. After the jet milling, classify, collect the particles with a particle size of less than 300nm for later use, and return the particles with a particle size greater than 300nm for jet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com