A kind of braided vena cava filter and braiding method

A vein and filter technology, applied in the fields of filters in blood vessels, medical science, prostheses, etc., can solve the problems of collapse of the filter structure, damage to the inner wall of the vena cava, poor blood circulation, etc., and achieve good shape memory function and high elasticity and compliance. Good sex, low stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

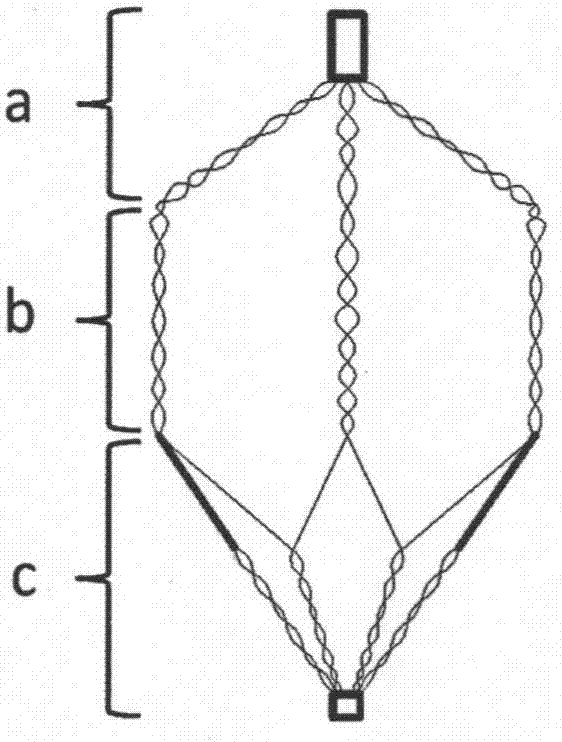

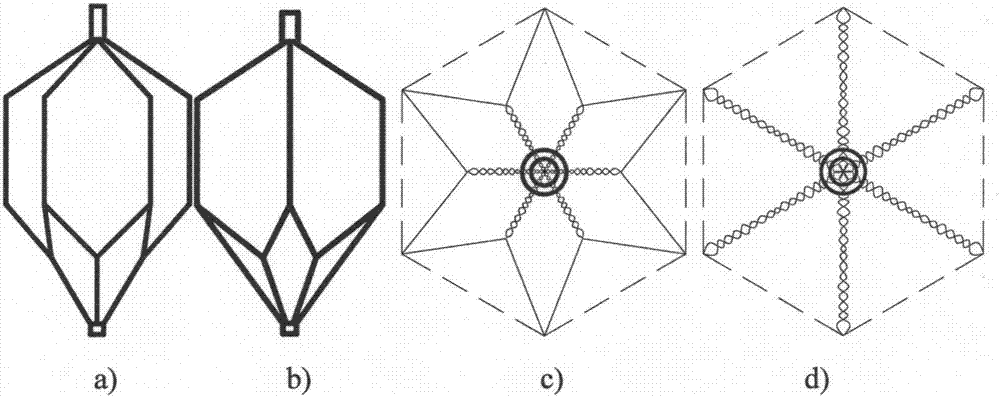

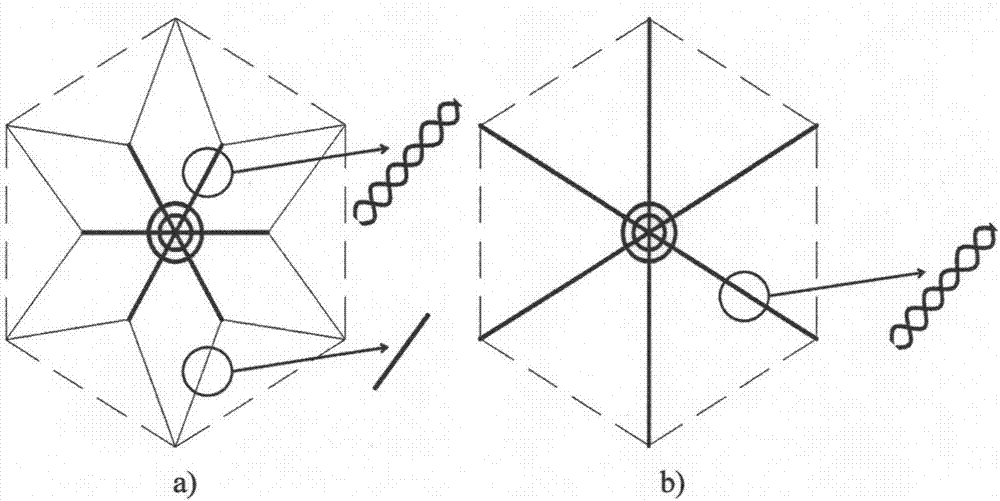

[0063] Such as figure 2 a) to figure 2 d) and image 3 a) to image 3 As shown in b), the cone mesh at the proximal end starts from the ligature steel sleeve, and 12 NiTi alloy wires are braided in pairs to form 6 Y-shaped braided structures, and the 6 Y-shaped braided structures are evenly distributed in the circumferential direction. The root of each Y-shaped braided structure is 2 NiTi wires, and the two branches are 1 NiTi wire respectively. The two adjacent NiTi wires of the two adjacent Y-shaped braided structures are merged and continue to be braided to form the middle fixing part. At this time, each of the six braided metal wires in the fixing part is composed of two NiTi wires. 6 braided metal wires extend to the distal end to form a tapered network at the distal end, and each braided metal wire continues to weave into an I-shaped braided structure, which is divided into cones and brought together, and finally fixed by a steel sleeve .

Embodiment 2

[0065] As shown in Figure 4a) and Figure 4 As shown in b), the cone mesh at the proximal end starts from the ligature steel sleeve, and 18 NiTi alloy wires are braided together to form 6 Y-shaped braided structures, and the 6 Y-shaped braided structures are evenly distributed in the circumferential direction. The root of each Y-shaped braided structure is 3 NiTi wires, and the two branches are 2 NiTi wires and 1 NiTi wire respectively. The two adjacent branches of the two adjacent Y-shaped braided structures are merged and continue to be braided into the middle fixing part. At this time, the six braided metal wires of the fixing part are each composed of three NiTi wires. 6 braided metal wires extend to the distal end to form a tapered network at the distal end, and each braided metal wire continues to weave into an I-shaped braided structure, which is divided into cones and brought together, and finally fixed by a steel sleeve .

Embodiment 3

[0067] Such as Figure 5 a) and Figure 5 As shown in b), the conical mesh at the proximal end starts from the ligature steel sleeve, and 24 NiTi alloy wires are braided in pairs to form 6 Y-shaped braided structures, and the 6 Y-shaped braided structures are evenly distributed in the circumferential direction. The root of each Y-shaped braided structure is 4 NiTi wires, and the two branches are respectively 2 NiTi wires. The two adjacent branches of the two adjacent Y-shaped braided structures are merged and continue to be braided into the middle fixing part. At this time, the six braided metal wires in the fixing part are each composed of four NiTi wires. 6 braided metal wires extend to the distal end to form a tapered network at the distal end, and each braided metal wire continues to weave into an I-shaped braided structure, which is divided into cones and brought together, and finally fixed by a steel sleeve .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com