Double main thread master-slave type three-helix energy-saving lamp filament and manufacturing method thereof

A manufacturing method and triple-helix technology, which is applied to the dual-main-filament main-assistant triple-helix energy-saving lamp filament and its production field, can solve the problems of unsatisfactory life of the lamp tube, insufficient contact area, and low product qualification rate, and achieve Easy to activate electronic powder, improve service life, high storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

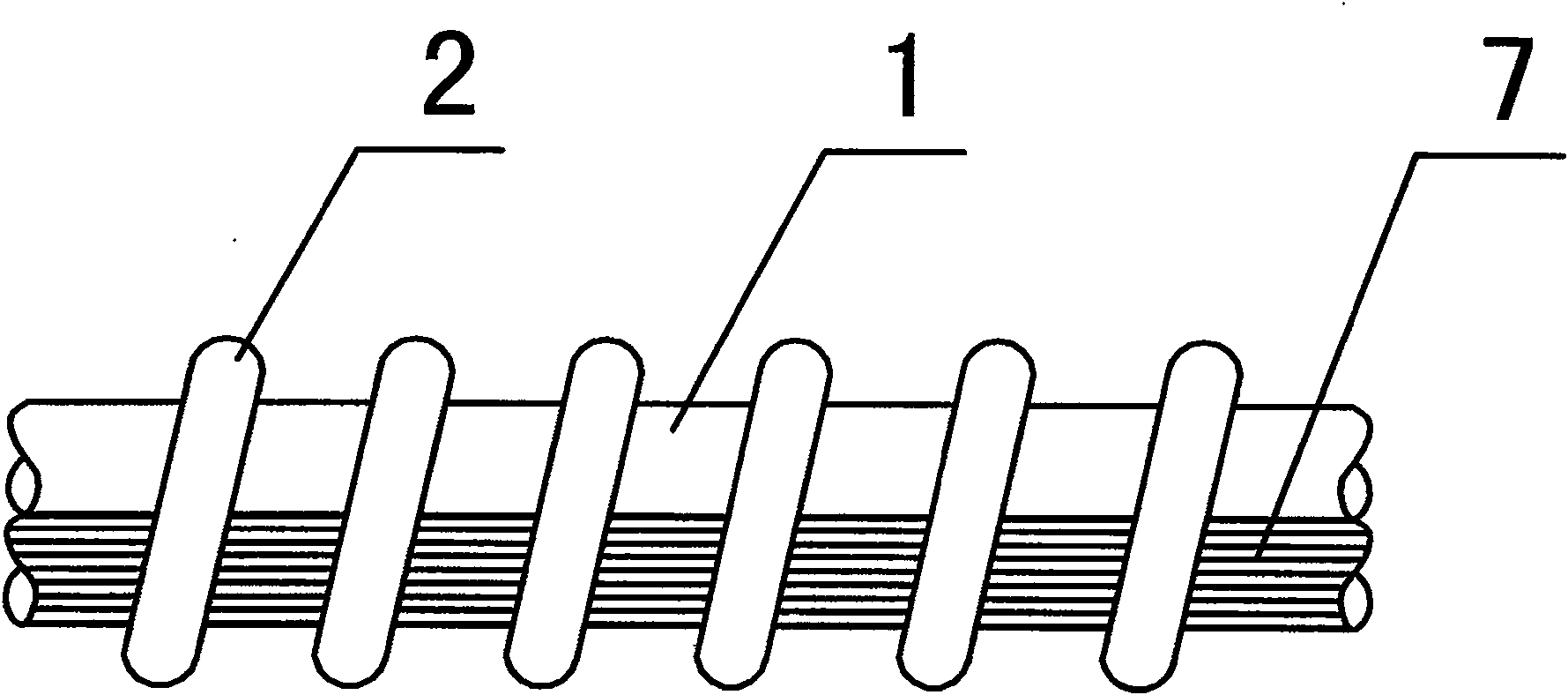

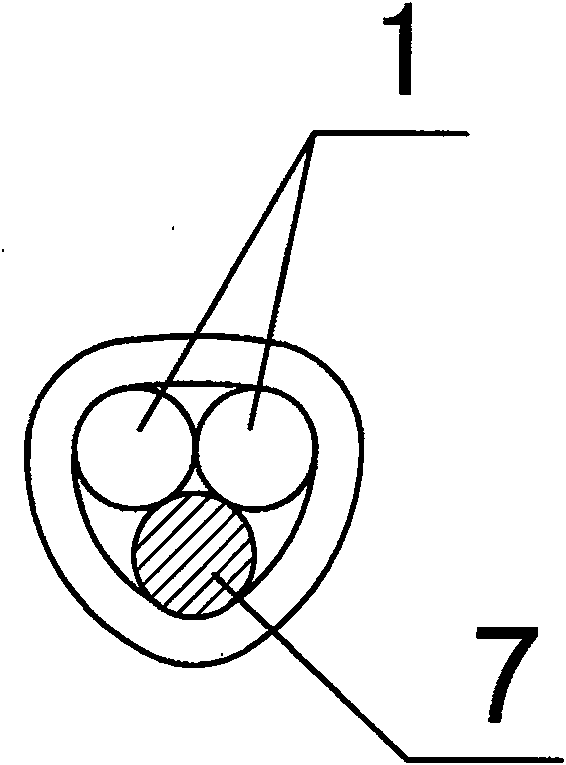

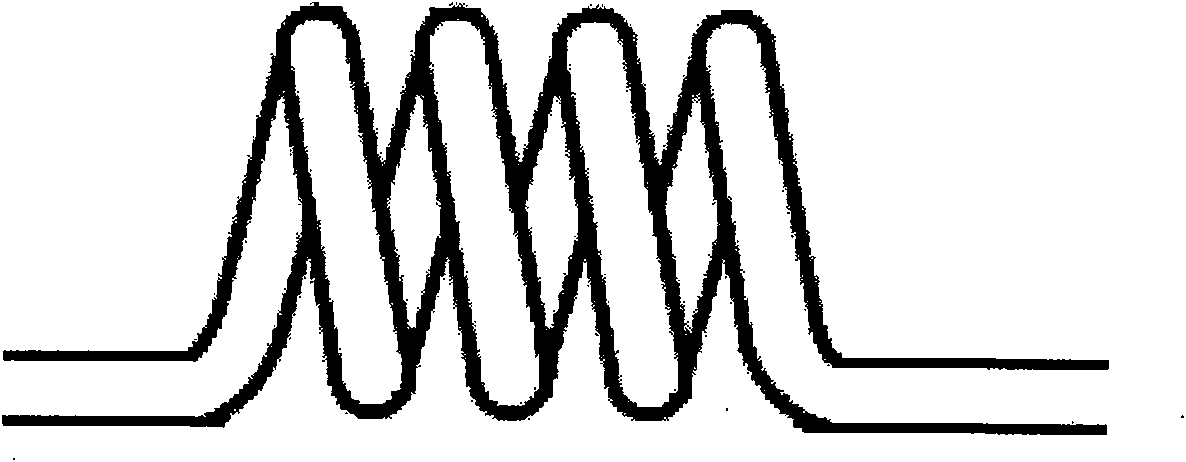

[0024] Example 1. like image 3 , 4 As shown, it is spirally wound by the filament secondary winding body 4, wherein the filament secondary winding body 4 is spirally wound by the filament primary winding body 3, as shown in Figure 5 shown. The filament primary winding body 3 is composed of two parallel and close main tungsten wires 1 and one molybdenum wire 7, and an auxiliary tungsten wire 2 spirally wound on the two main tungsten wires 1 and molybdenum wire 7 Coiled, the diameters of the two main tungsten wires 1 are the same, such as figure 1 , 2 shown. The diameter and spiral coefficient of the main tungsten wire 1 and the auxiliary tungsten wire 2 should be selected according to the power of the lamp. The diameters of the two main tungsten wires 1 can also be different, and the resistance can be adjusted through different combinations of the diameters of the two main tungsten wires 1 .

[0025] When processing, such as figure 1 , 2 As shown, firstly, two main t...

Embodiment 2

[0026] Example 2. It is spirally wound by the secondary winding body 4 of the filament, wherein the secondary winding body 4 of the filament is spirally wound by the primary winding body 3 of the filament; the primary winding body 3 of the filament is composed of two parallel and close Main tungsten wire 1 and molybdenum wire 7, and two auxiliary tungsten wires 2 that are spirally wound on the two main tungsten wires 1 and molybdenum wire 7 are wound together. The main tungsten wire 1 and auxiliary tungsten wire 2 The diameter and spiral coefficient should be selected according to the power of the lamp.

[0027] During processing, the two main tungsten wires 1 and the molybdenum wire 7 are parallel and close together, and the two auxiliary tungsten wires 2 are spirally wound on the two main tungsten wires 1 and the molybdenum wire 7 on the ordinary wire winding machine. Firstly, the primary winding body 3 of the filament is obtained; then the primary winding body 3 of the fil...

Embodiment 3

[0028] Example 3. It is spirally wound by the secondary winding body 4 of the filament, wherein the secondary winding body 4 of the filament is spirally wound by the primary winding body 3 of the filament; the primary winding body 3 of the filament is composed of two parallel and close The main tungsten wire 1 and molybdenum wire 7, and three auxiliary tungsten wires 2 that are spirally wound on the two main tungsten wires 1 and molybdenum wire 7 are wound. The diameter of the main tungsten wire 1 and the auxiliary tungsten wire 2 The size and spiral coefficient should be selected according to the power of the lamp.

[0029] During processing, the two main tungsten wires 1 and the molybdenum wires are parallel and close together, and the three auxiliary tungsten wires 2 are spirally wound on the two main tungsten wires 1 and the molybdenum wire 7 on the ordinary wire winding machine. , to obtain the filament primary winding body 3; then the filament primary winding body 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com