PVDC (polyvinyl dichloride) composition for spinning

A composition and spinning technology, which is applied in the field of PVDC compositions, can solve the problems of poor thermal stability and flame retardancy of PAN-based fibers, poor heat resistance of protein-based fibers, and high thermal shrinkage, and achieve spinning performance and processing heat Good stability, improved thermal stability and processing performance, and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

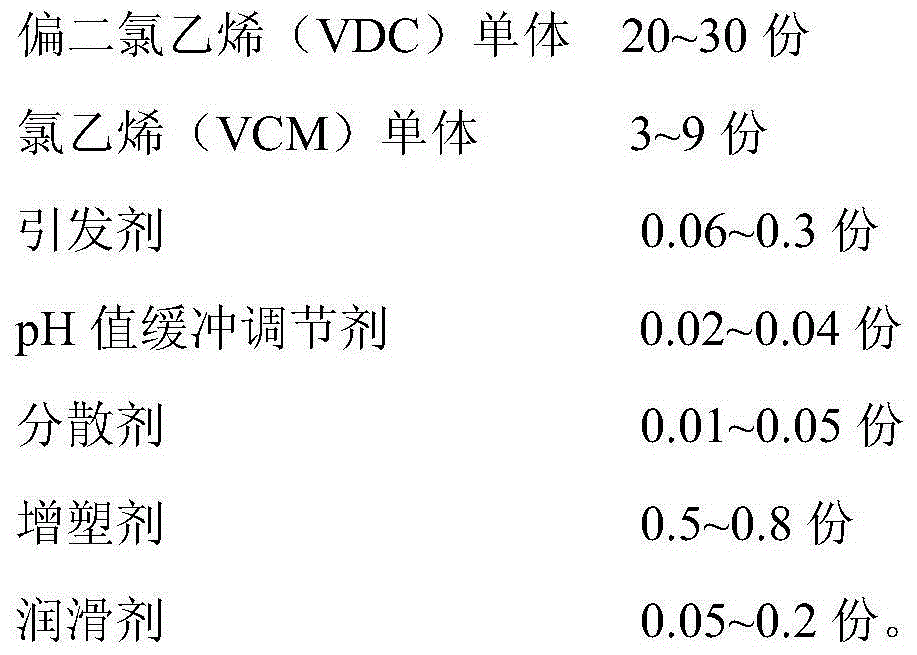

[0023] A kind of PVDC composition for spinning, its raw material formula is as follows:

[0024]

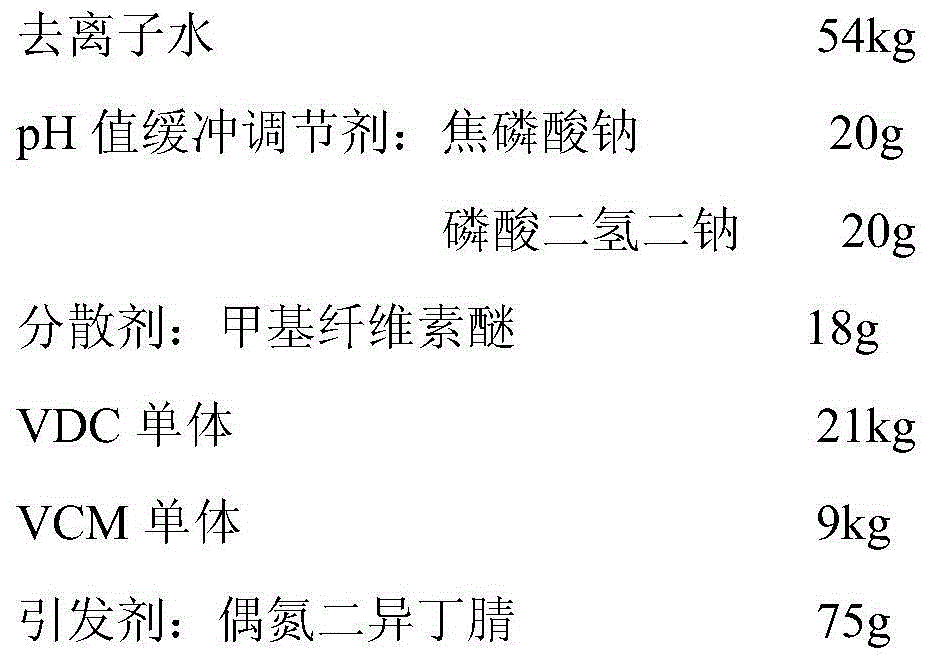

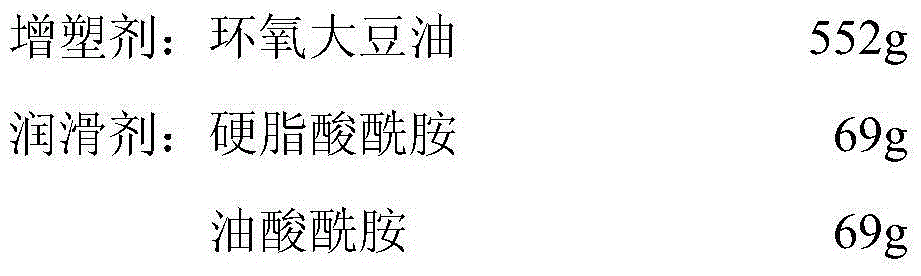

[0025]

[0026] The preparation method is as follows:

[0027] (1) Preparation of pH value buffer regulator aqueous solution and dispersant aqueous solution: 20 g of sodium pyrophosphate and disodium dihydrogen phosphate 20 g are mixed with deionized water 2 kg to prepare pH value buffer regulator aqueous solution; methyl cellulose ether 18 g, Use 9kg of deionized water to prepare an aqueous dispersant solution;

[0028] (2) Put 5kg of deionized water into a 100L polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, double-layer two-page 45° inclined paddle), seal the kettle for pressure test and vacuumize, then add the preparation Good VDC monomer, VCM monomer, and azobisisobutyronitrile were dispersed at a speed of 120rpm / min for 10 minutes, and then an aqueous solution of a dispersant, an aqueous solution of ...

Embodiment 2

[0033] A kind of PVDC composition for spinning, its raw material formula is as follows:

[0034]

[0035]

[0036] The preparation method was the same as that in Example 1, and the result: the polymerization process was stable, without concentrated exothermic phenomenon, and the obtained white resin with uniform particles had good stability, a viscosity of 1.461, and a molecular weight of 87,952.

Embodiment 3

[0038] A kind of PVDC composition for spinning, its raw material formula is as follows:

[0039]

[0040] The preparation method was the same as in Example 1, and the result: the polymerization process was stable, without concentrated exothermic phenomenon, and the obtained white resin with uniform particles had good stability, a viscosity of 1.478, and a molecular weight of 90239.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com