High-speed plastic circular weaving machine capable of preventing all strands of warp yarn from being ground

A circular loom and warp thread technology, applied in the field of high-speed plastic circular looms, can solve the problems of thread breakage, large movement wear, affecting normal production, etc., so as to avoid thread breakage and improve the running speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments are further described in detail below in conjunction with accompanying drawings

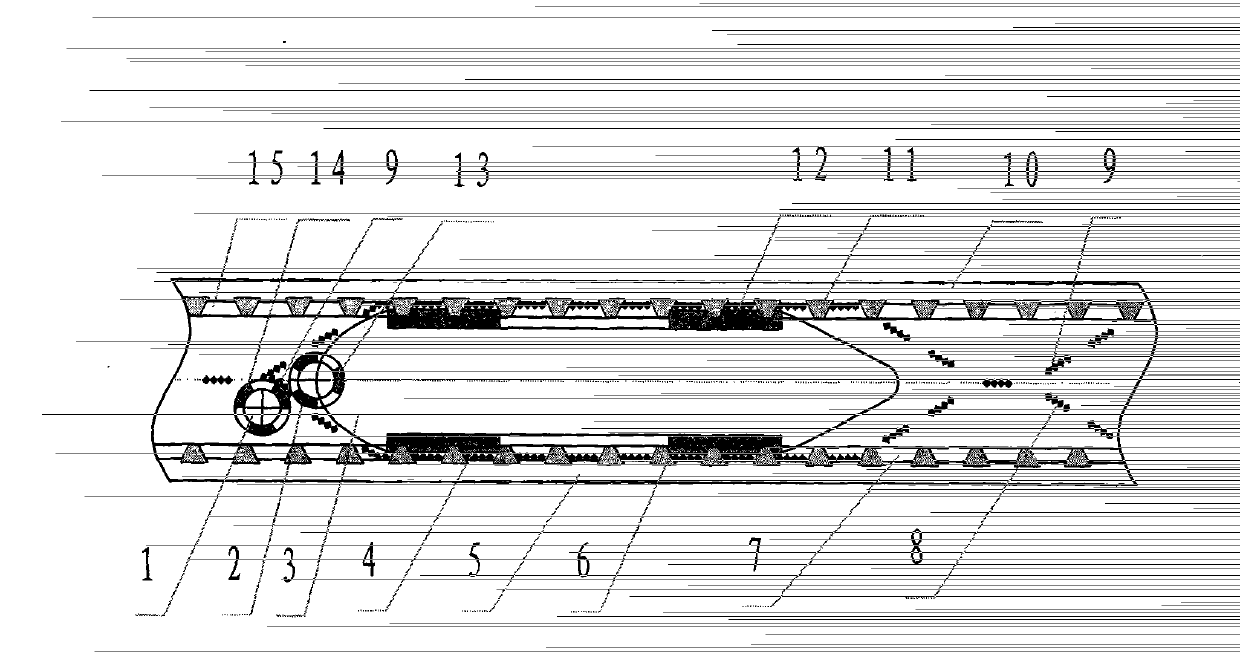

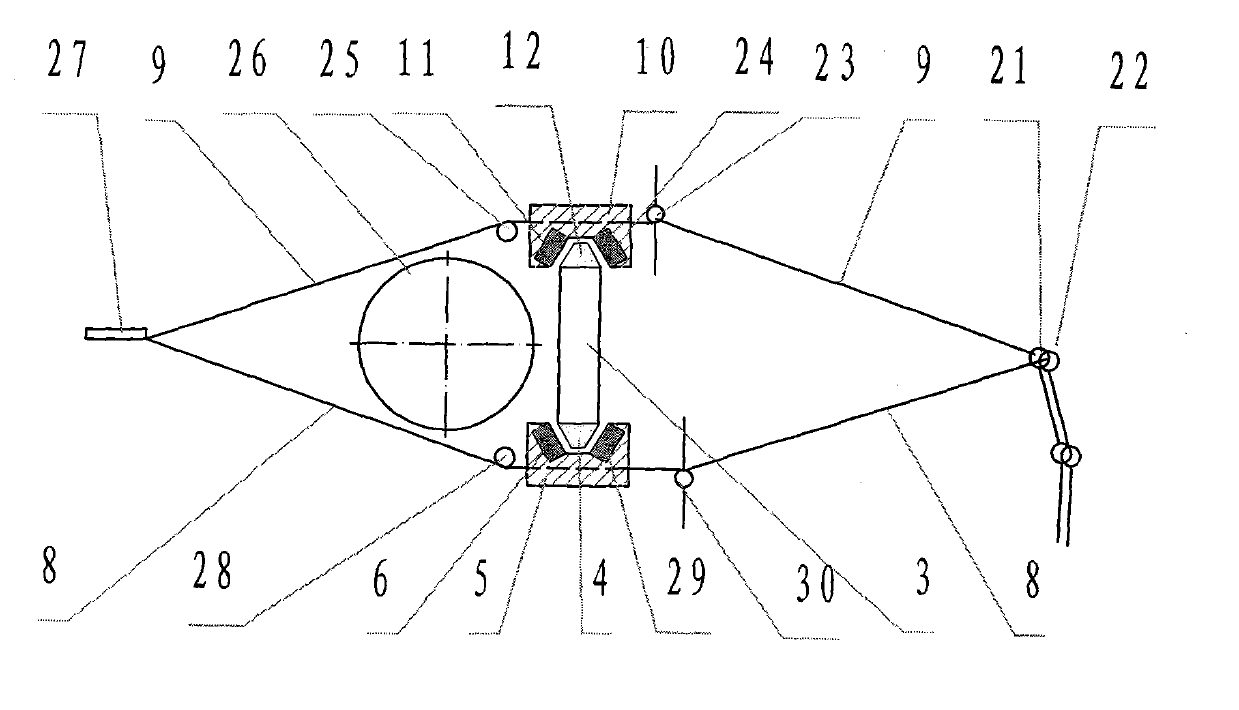

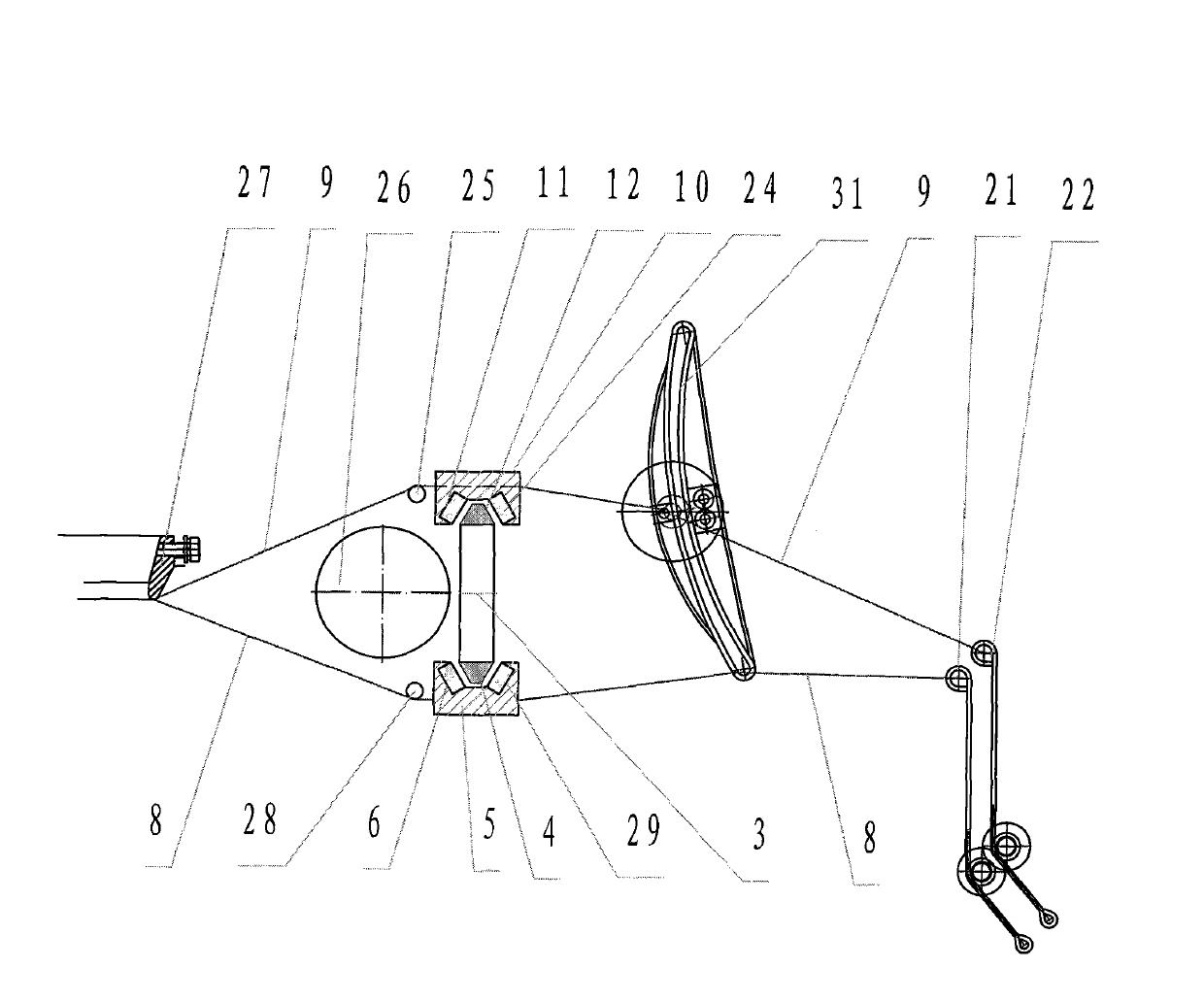

[0011] refer to figure 1 : figure 1 It is a schematic diagram of the structure of an embodiment of a high-speed plastic circular loom that is completely free from warp grinding, 1-shuttle push wheel, 2-shuttle rear wheel, 3-shuttle boat, 4-shuttle boat lower edge magnet, 5-lower door ring, 6-The inner ring magnet of the lower door ring, 7-The warp line passing through the groove of the lower door ring, 8-The warp line A, 9-The warp line B, 10-The upper door ring, 11-The inner ring magnet of the upper door ring, 12-The upper edge magnet of the shuttle boat, 13 - magnets on the outer surface of the shuttle rear wheel, 14 - the magnets on the outer surface of the shuttle wheel, 15 - the upper door ring warp thread passing groove, a kind of warp thread free of rolling high-speed plastic circular loom, it is characterized in that: the rear part of the shuttle boat 3 is installed T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com