Plastic circular weaving machine

A technology of circular looms and plastics, applied in circular looms, looms, textiles, etc., can solve problems such as time-consuming and labor-intensive, unfavorable product promotion and sales, and increased use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

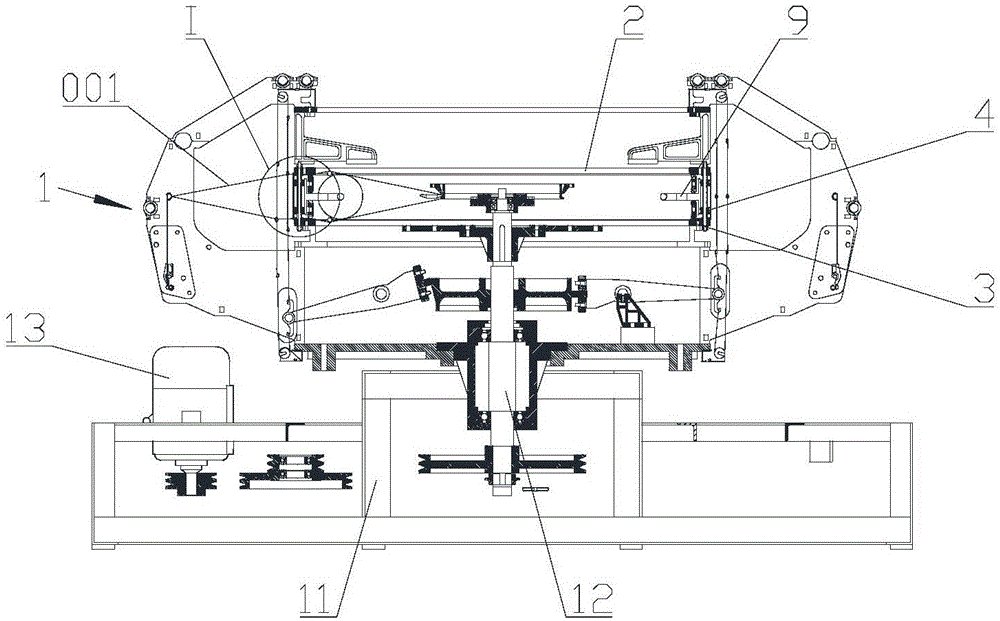

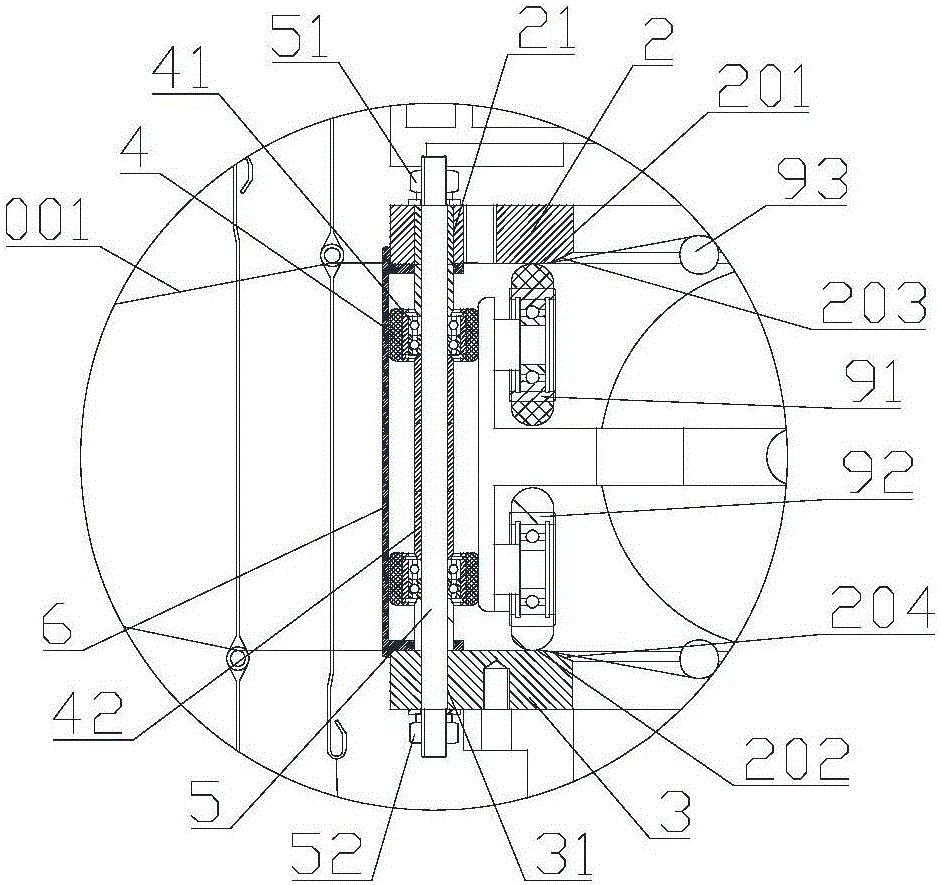

[0025] Such as figure 1 and figure 2 As shown, the present invention provides a kind of plastic circular loom, comprises main frame 1, and main frame 1 comprises frame 11, main shaft 12, door ring assembly and shuttle 9, is provided with motor 13 on frame 11, and main shaft 12 is driven by motor 13, The door ring assembly is installed on the frame 11, and the shuttle 9 is installed on the main shaft 12. The door ring assembly includes an upper door ring 2 and a lower door ring 3, and a plurality of rollers 4 are arranged between the upper door ring 2 and the lower door ring 3, and the rollers 4 The wheel shaft 5 is connected with the door ring assembly, and the roller 4 is distributed along the circumferential direction of the door ring assembly and forms a rolling track for the shuttle 9 to run. The shuttle 9 is provided with an upper limit wheel 91 and a lower limit wheel 92, and the lower surface of the upper door ring 2 There is an upper track surface 201 for the upper l...

Embodiment 2

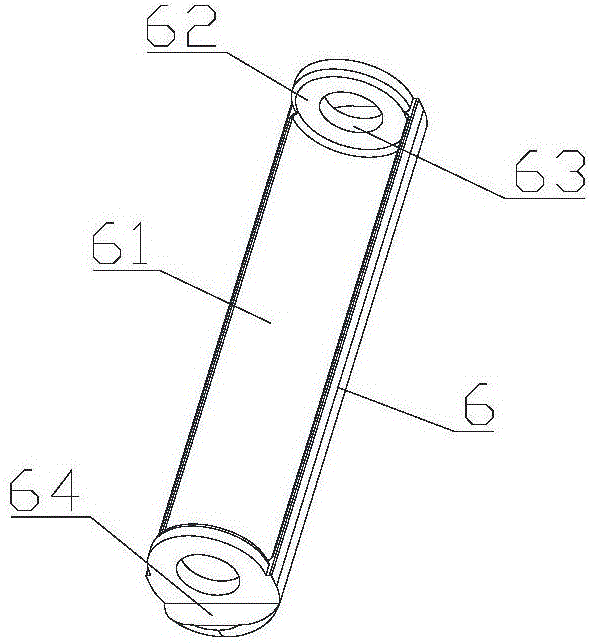

[0034] In this embodiment, the accommodation groove 61 has been improved, that is, how many rollers 4 are on a wheel shaft 5, and how many accommodation grooves 61 are set on a support member 6 correspondingly, as Figure 5 , Figure 6 and Figure 7 As shown, corresponding to the two rollers, one supporting member 6 is provided with two receiving grooves 61 correspondingly, and the receiving grooves 61 are connected through the matching groove 65, the depth of the matching groove 65 is smaller than the depth of the receiving groove 61, and the matching groove 65 An arc-shaped boss 66 is provided, and the arc-shaped boss 66 is to cooperate with the axle sleeve 42 on the wheel shaft 5 to limit the position of the axle sleeve 42. Since the wheel shaft 5 and the axle sleeve 42 will not move during the operation of the shuttle 9 Rotate, so the middle part of the support member 6 cooperates with the shaft sleeve 42, which can improve the supporting effect.

[0035] The content not...

Embodiment 3

[0037] In addition to connecting the top of the wheel shaft 5 with the upper door ring 2 and the bottom end with the lower door ring 3, the wheel shaft 5 can also be divided into two parts, such as Figure 8 As shown, the wheel shaft 5 includes an upper wheel shaft 501 connected with the upper door ring 2 and a lower wheel shaft 502 connected with the lower door ring 3, the bottom end of the upper wheel shaft 501 is suspended, and a roller 4 is arranged on the upper wheel shaft 501, and the top of the lower wheel shaft 502 Suspended, a roller 4 is provided on the lower axle 502 . The number of rollers on the upper wheel shaft 501 and the lower wheel shaft 502 can be increased as required. Since each roller can be removed individually, the rollers 4 can be replaced quickly and in a more targeted manner.

[0038] For the content not described in this embodiment, reference may be made to Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com