Plastic circular weaving machine with rolling track and without shuttle wheel

A technology for circular looms and rails, applied to circular looms, looms, textiles, etc., can solve problems such as short service life, difficult manufacturing, and non-compliance with environmental protection requirements, achieve convenient installation and maintenance, and overcome shuttle wheel rolling The effect of warp pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

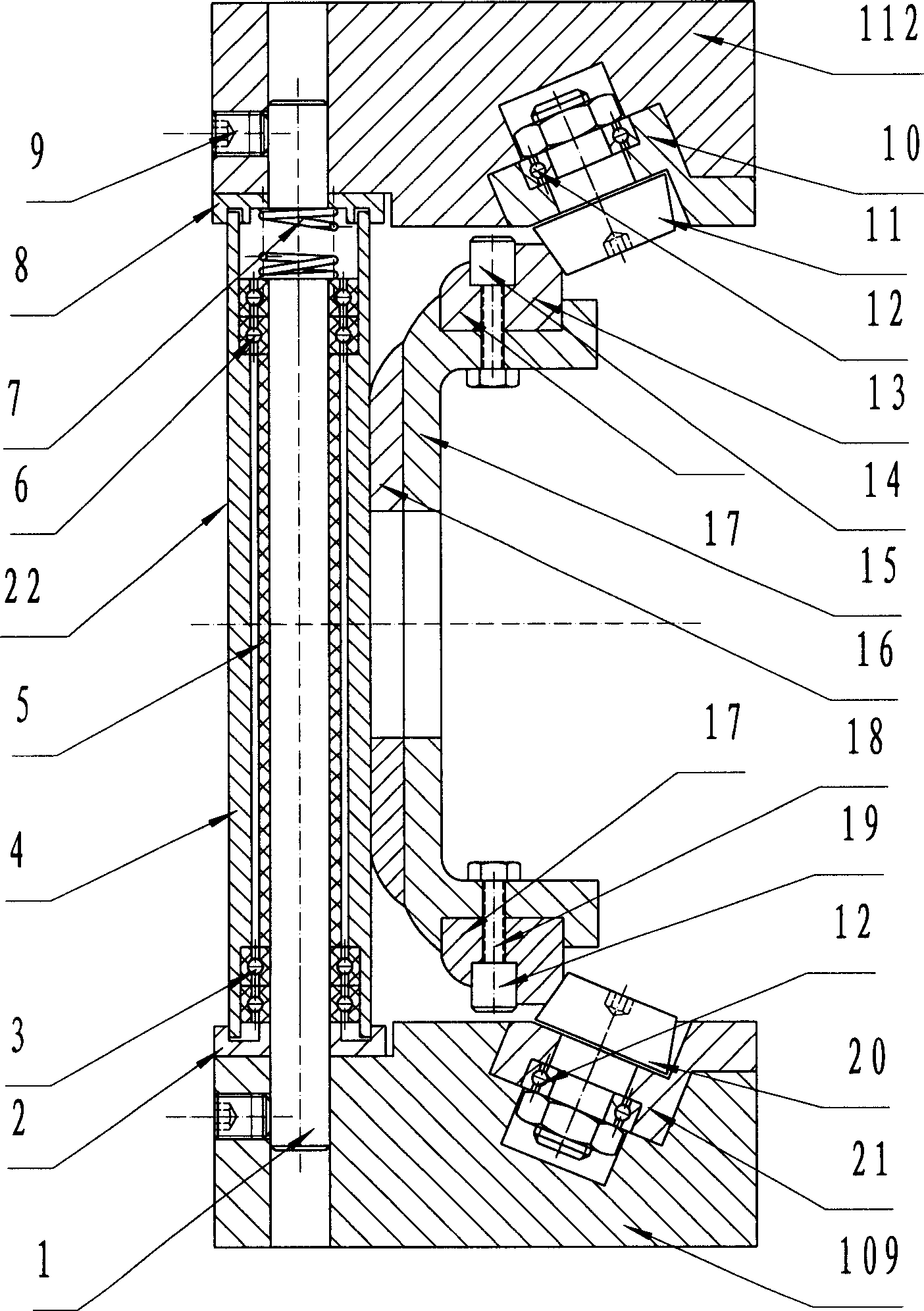

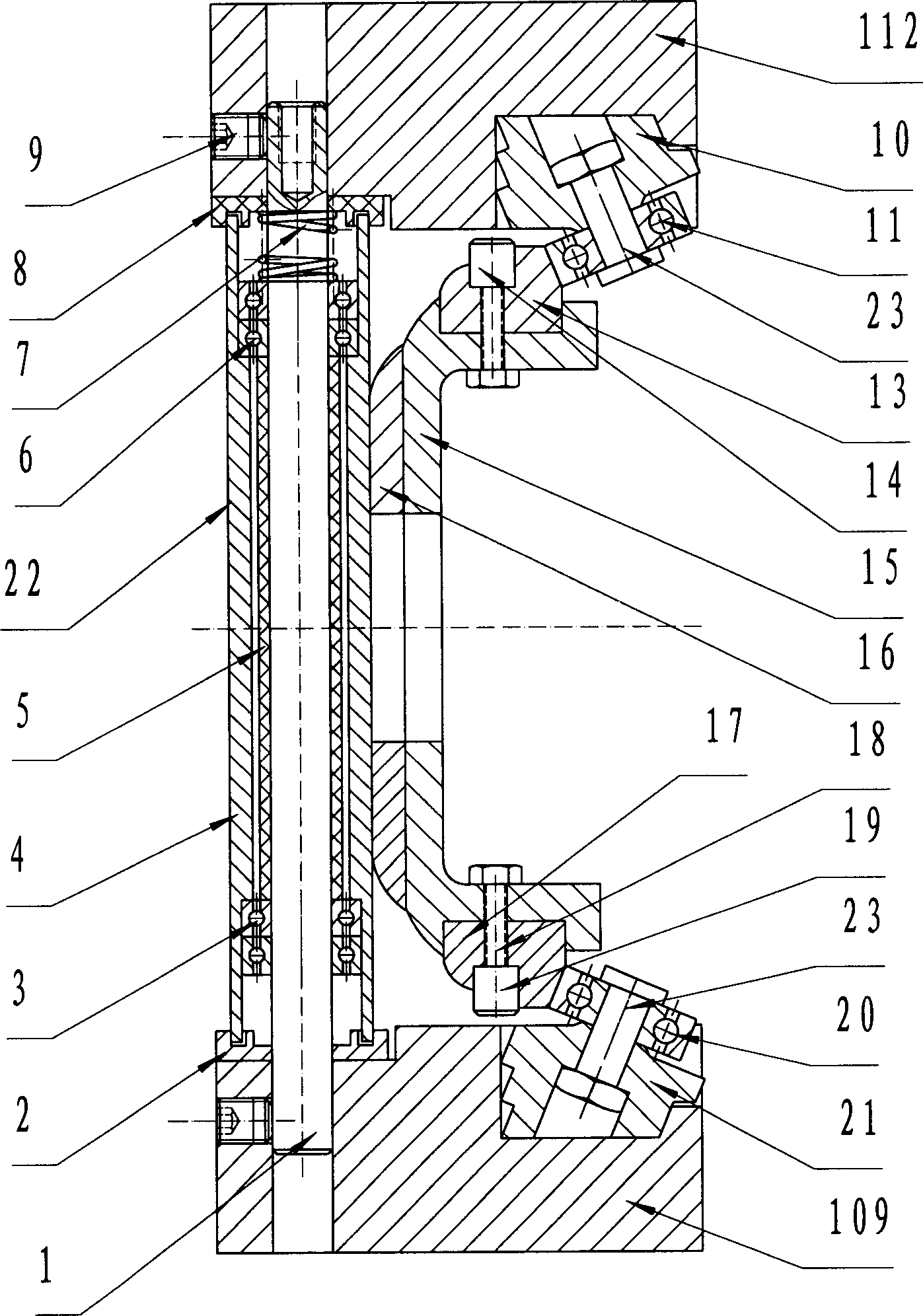

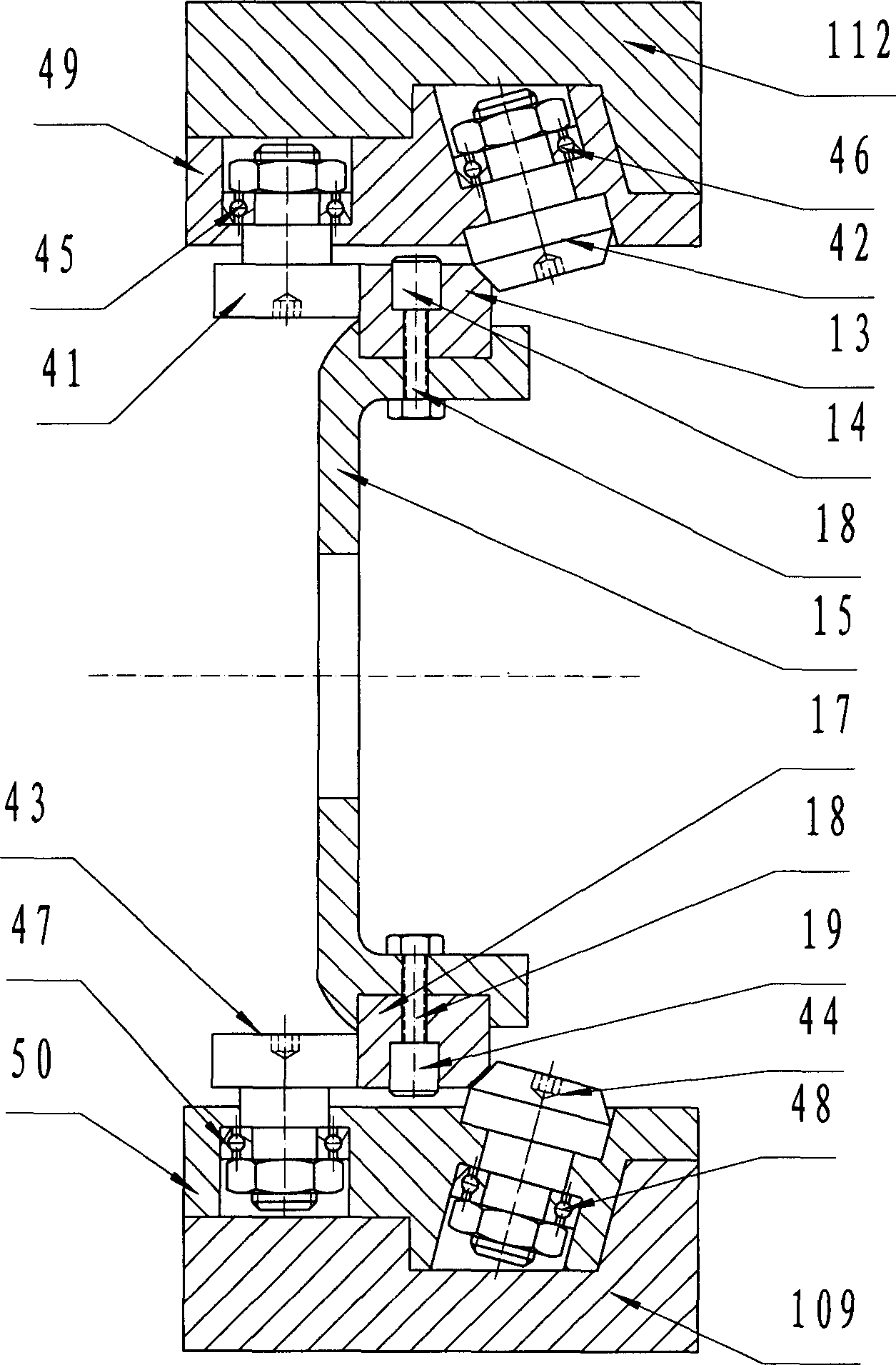

[0037] refer to figure 1 , figure 1 It is a structural diagram of an embodiment of the present invention. The rolling track of the shuttleless plastic circular loom is composed of a drum body and a roller part. The drum body structure includes a fixed column (1), a lower sealing positioning ring (2) and a lower bearing ( 3), roller (4), positioning sleeve (5), upper bearing (6), spring (7), upper sealing ring (8). The roller part comprises an upper bearing seat (10), an upper roller (11), a bearing (12), a lower roller (20), and a lower bearing seat (21). 30-288 fixed columns are fastened on the upper and lower door rings (112) (109) by screws (9) evenly distributed on the circumference, and the fixed columns are covered with lower sealing positioning sleeves (2), lower bearings (3), and rollers ( 4), positioning sleeve (5), upper bearing (6), spring (7), upper sealing ring (8), inner rings of upper and lower bearings (6) (3) tightly fit with fixed column (1), upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com